Construction method and hole sealing structure for super-large section tunnel for traversing coal measure strata section

A technology for coal-measure strata and super-large cross-section, which is used in earth-moving drilling, sealing/packing, wellbore/well components, etc., and can solve the technical method of incomplete coal and gas burst tunnel construction, and gas tunnel construction can be used for reference It can reduce the amount of fracturing preparation work, improve the efficiency of tunnel driving, and have a strong pressure bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

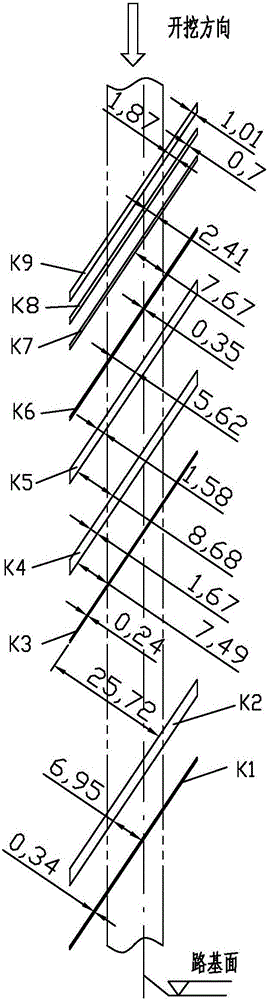

[0026] Example 1, a construction method for a super-large-section tunnel passing through coal-measure strata, including the steps of hydraulic fracturing and gas extraction, the method is used for excavation of a tunnel that crosses a total of 9 coal seams from K1 to K9 in a certain design, according to the geological The true thickness and spacing of K1~K9 coal seams in the survey results, such as figure 1 Shown, where the unit of thickness and spacing is m.

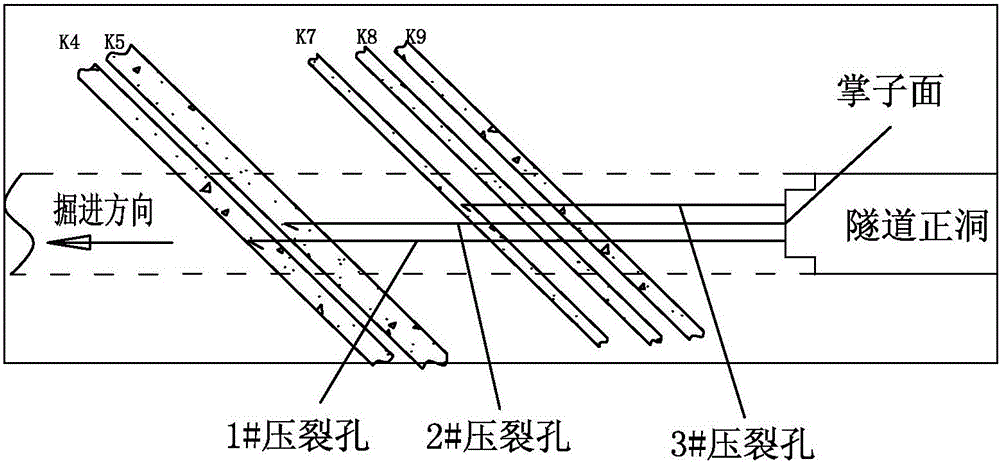

[0027] According to the above-mentioned geological prospecting data of the coal-measure strata section to be crossed, it is determined that the 9 coal seams in the coal-measure strata section adopt two concentrated fracturing methods to perform multiple fracturing on multiple coal seams. ~K4 coal seam, the second concentrated fracturing is carried out on K3~K1 coal seam.

[0028] When the minimum vertical distance from the tunnel excavation face to the roof of the K9 and K3 coal seams is 10m, the average coal seam thic...

Embodiment 2

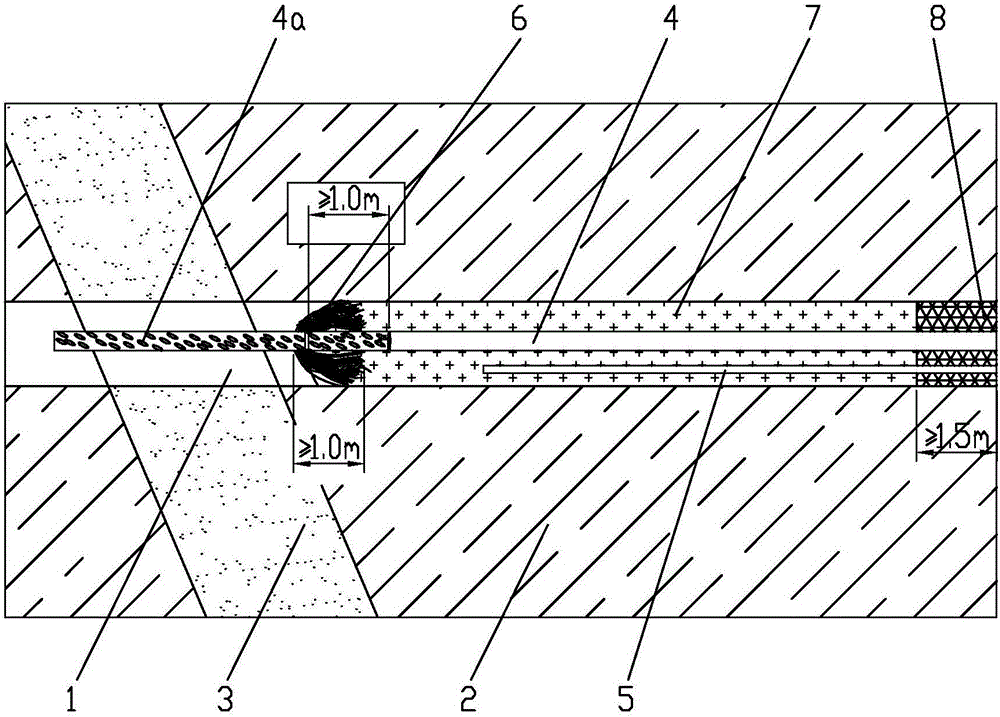

[0034] Example 2, see Figure 4 , a concentrated hydraulic fracturing drilling and sealing structure in which super-large-section tunnels pass through multiple coal seams, including a plurality of fracturing drillings 1 corresponding to the number of times of centralized fracturing, and sealing holes are correspondingly arranged in each fracturing drilling 1 device, and form a sealing structure through the corresponding sealing device, the sealing device extends from the coal seam roof 2 direction into the corresponding coal seam 3, the sealing device includes a fracturing pipe 4, a grouting pipe 5, and a device is formed at the inner end of the fracturing pipe 4 The flower tube section 4a of fixed length, the flower tube section 4a is divided into the inner section of the flower tube and the outer section of the flower tube by the binding part through the horsetail 6, the inner section of the flower tube is used for hydraulic fracturing, and the outer wall of the outer section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com