Tree-digging machine with soil balls

A tree digging machine and soil ball technology, applied in forestry, application, agriculture, etc., can solve the problems of difficult operation, time-consuming, easy to scatter, etc., and achieve the effect of improving labor efficiency, scientific and reasonable design, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

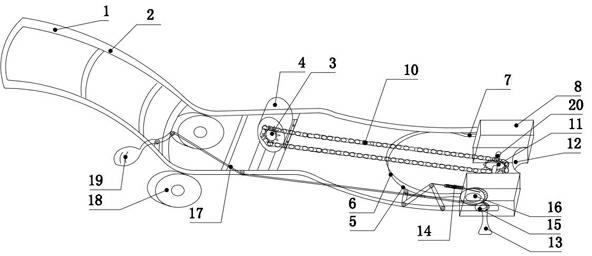

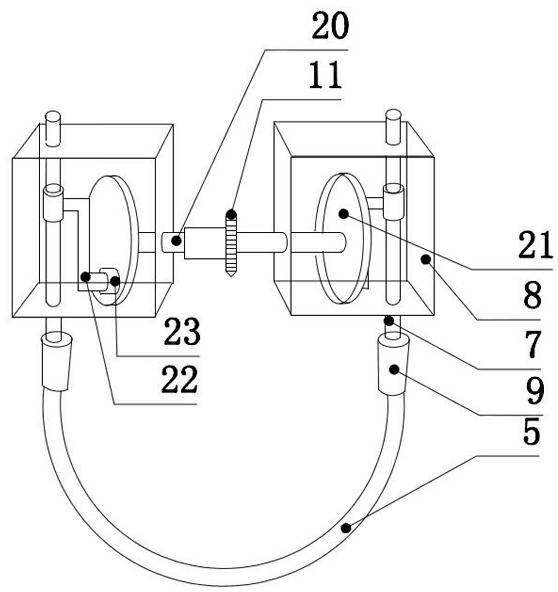

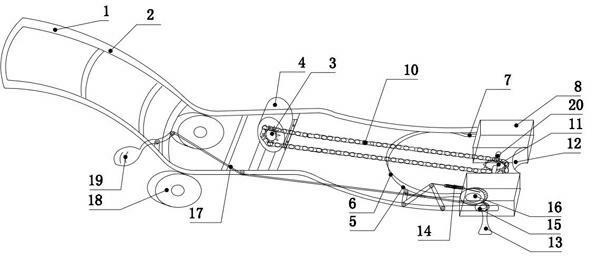

[0021] Such as figure 1 with figure 2 As shown, the tree digging machine with soil ball of the present invention comprises a frame 2, a motor 4 arranged on the upper side of the middle part of the frame 2 and a wheel 18 arranged on the lower side of the middle part of the frame 2, and the rear part of the frame 2 is upwardly bent into Arc-shaped handrail 1, the lower end of the handrail 1 is provided with a rotary pedal 19, the front part of the frame 2 is curved downward to form an arc, and a vibration box 8 is movable on both sides of the top, and the two vibration boxes 8 share a power shaft 20 The power shaft 20 is inserted into the top end of the vibrating box 8 through the bearing arranged on the inside of the vibrating box 8. A disc 21 is installed on the top of the vibrating box 8. An eccentric fixed shaft 23 is arranged on the disc 21. The fixed shaft 23 connects with the small connecting rod 22. The vibration connecting rod 7 installed in the two through holes on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com