Roadheader cutting head with harrow teeth, telescopic structure thereof and accessory drilling tool

A telescopic structure and cutting head technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems that the cutting head will not expand and retract slag removal, it is unrealistic, and the focus area is limited, so as to save labor and save energy in blasting. The effect of reducing the distance between the medicine and the slag and reducing the degree of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

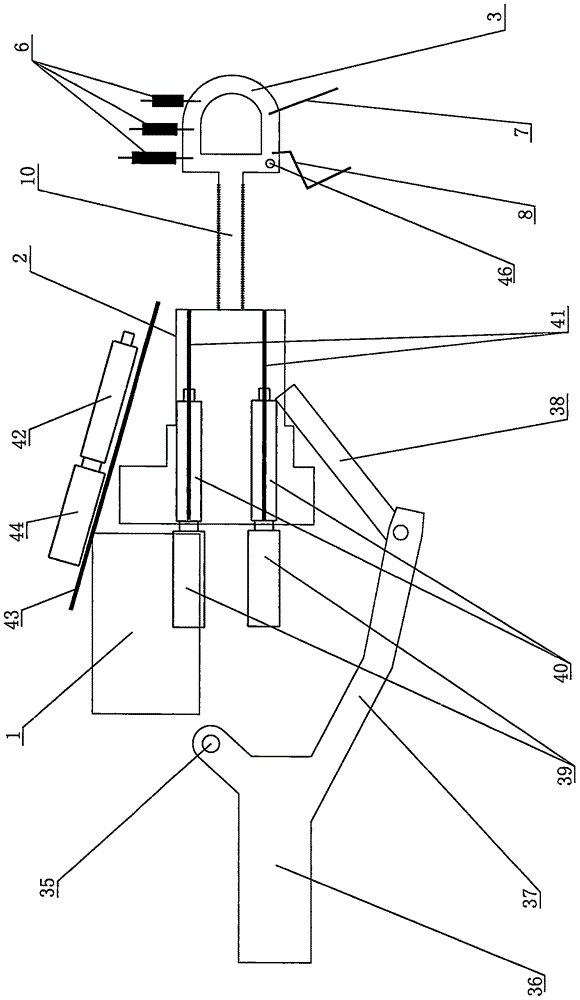

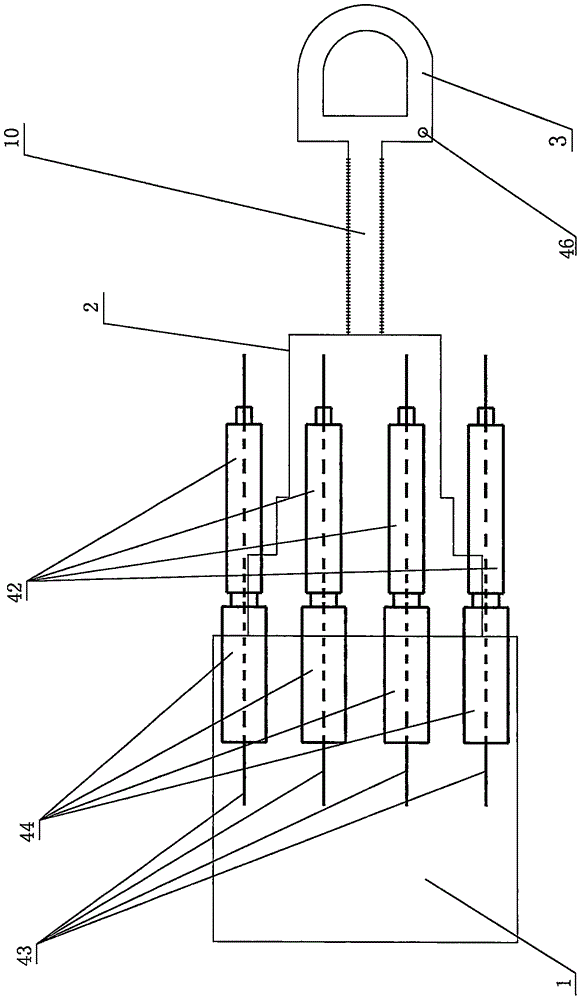

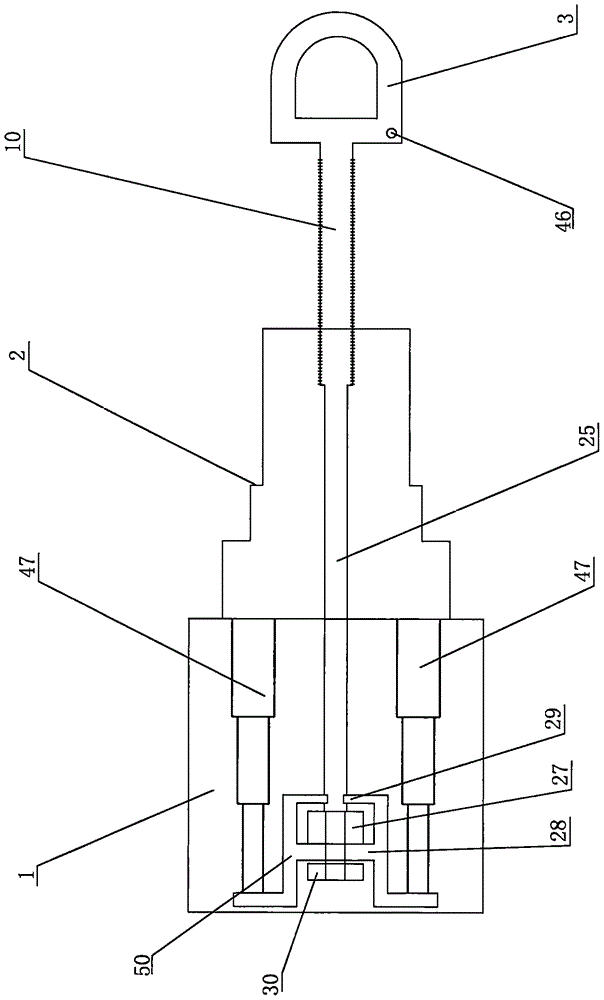

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0027]Among the above-mentioned accompanying drawings: the structure of the first embodiment when the present invention is used is shown; Referring to the accompanying drawings, its basic structure is: the roadheader cutting head with rake teeth and its telescopic structure and accompanying drilling tool are existing The cutting arm and cutting head of the roadheader are remade. Now take a certain type 260 roadheader as an example. The characteristics are: the original telescopic structure of the coal roadway is still used, and the telescopic activity is increased to 1 meter or more. Long, the spline sleeve 11 part of about 480 mm outer diameter and 200 mm inner diameter, lengthened thereupon, and the front end has a ball retaining cover 15, a ring seal ring 14, and a gland 13 with an outer diameter of about 350 mm and an inner diameter of 200 mm , their i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com