Folding-arm type tunneling machine capable of monitoring intelligently and automatically regulating rotate speed of cutting head

An automatic adjustment and intelligent monitoring technology, applied in cutting machinery, slitting machinery, earth-moving drilling, etc., can solve the problems of lack of monitoring methods, roadheader failures relying on field experience, etc., to achieve a large amount of information transmission, anti-interference ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

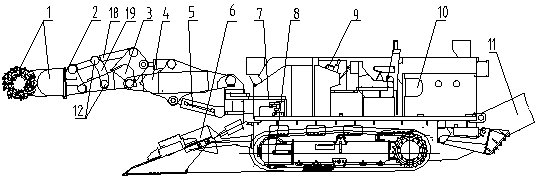

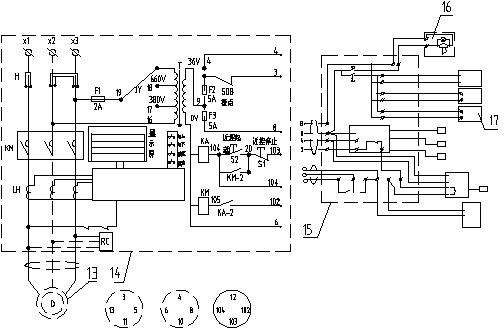

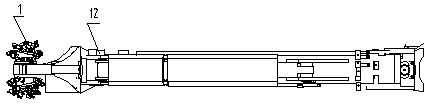

[0023] exist figure 1 and figure 2 Among them, the folding-arm roadheader with intelligent monitoring and automatic adjustment of the cutting head speed includes a working arm, a conveying mechanism 11, an operating mechanism 9, an electrical system 10, a hydraulic system 5, a traveling mechanism 8 and a vehicle body 7. The conveying Mechanism comprises shovel part 6, and described working arm comprises cutting head 1, spray frame 2, arm 3 and big arm 4, and one end of described working arm is movably connected with vehicle body 7, and described cutting head comprises cutting part and The power part used to drive the cutting head to rotate, the power part is respectively equipped with sensors for gas, dust and displacement monitoring, and the sensors for gas, dust and displacement monitoring are optical fiber sensors, and the optical fiber sensors pass through The fiber optic cable transmits the sensor monitoring data to the communication substation, and then transmits it to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com