a rock breaking device

A rock-breaking device and rock-breaking technology, applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problem of not being able to fundamentally eliminate blasting, and achieve the effect of safe excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

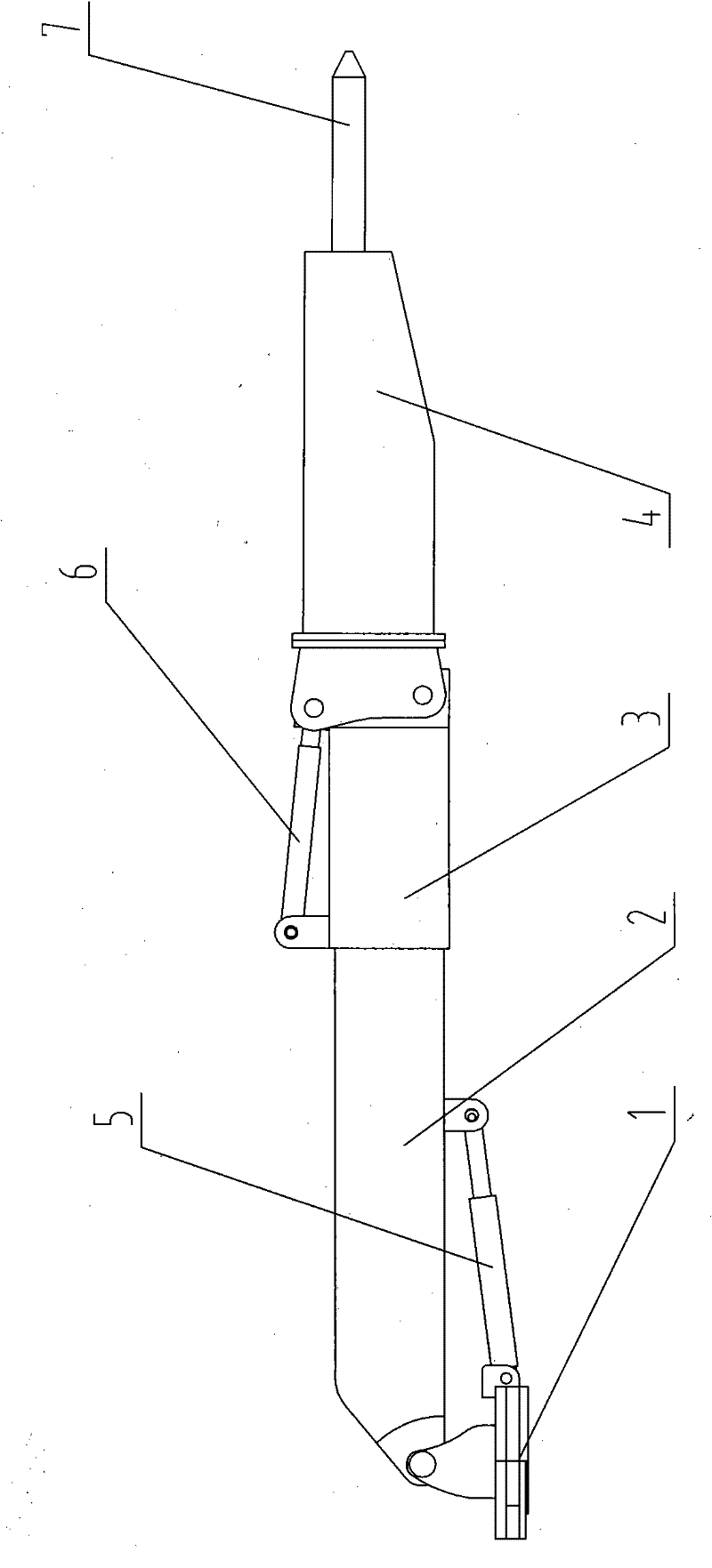

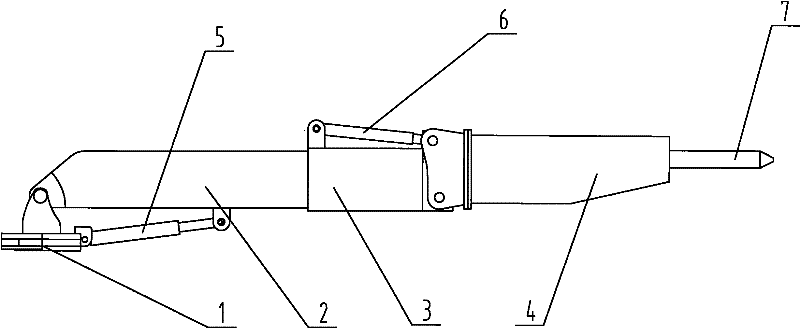

[0022] Such as figure 1 As shown, the rock-breaking device of the present invention mainly includes a rotary table 1, a rock-breaking arm (the telescopic outer arm 2 of the rock-breaking arm, and the telescopic inner arm 3 of the rock-breaking arm) and a breaking hammer 4, and one end of the rock-breaking arm is connected to the rotary table 1. The other end of rock arm is connected breaking hammer 4. The turntable 1 is installed on the carrier through the slewing bearing, and the turntable 1 is driven by a hydraulic cylinder or a hydraulic motor, which can realize the deflection around the rotary axis; the rock-breaking arm is a telescopic arm structure, which is driven by the hydraulic cylinder to realize the expansion and contraction of the rock-breaking arm. In this embodiment, the rock-breaking arm is a telescopic arm structure formed by connecting the telescopic inner arm 3 of the rock-breaking arm and the telescopic outer arm 2 of the rock-breaking arm. One end of 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com