Timely speed regulation internal gear planetary gear train mechanism of multi-rotor unmanned aerial vehicle

A multi-rotor unmanned aerial vehicle and planetary gear system technology, which is applied to aircraft parts, aircraft power transmission, aircraft power devices, etc., can solve the problems of difficult control of multi-rotor oil-powered unmanned aerial vehicles and difficulty in guaranteeing the rotor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

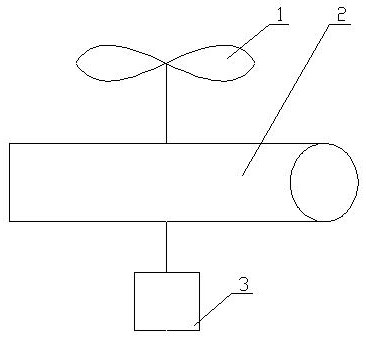

[0019] Specific implementation mode one: as figure 1 , figure 2 As shown, this embodiment discloses a multi-rotor unmanned aerial vehicle timely speed-adjustable internal tooth planetary gear train mechanism, which consists of a rotor 1, a planetary gear train 2, an engine 3, a speed-regulating motor 4, and a worm gear pair 5; The output shaft of the speed-regulating motor 4 is connected to one end of the worm of the worm-gear pair 5, and the worm of the worm-gear pair 5 is meshed with the ring gear 27 of the planetary gear train 2; the output shaft of the engine 3 is connected to the planetary gear The center wheel 26 of the gear train 2 is unidirectionally or fixedly connected; the middle part of the tie rod 28 of the described rotor 1 is unidirectionally or fixedly connected with the planetary gear train 2 .

specific Embodiment approach 2

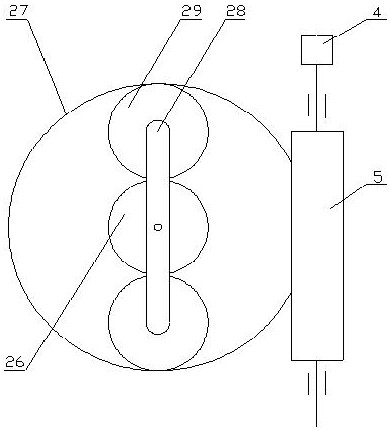

[0020] Specific implementation mode two: as figure 1 , figure 2 As shown, a kind of multi-rotor unmanned aerial vehicle described in the specific embodiment 1 timely adjusts the internal tooth planetary gear train mechanism, and the described planetary gear train 2 includes the sun gear 26, the ring gear 27, the tie rod 28 and two Planetary gear 29; the central gear 26 and two or more planetary gears 29 are all arranged inside the ring gear 27, the central gear 26 meshes with two or more planetary gears 29 at the same time, and the planetary gear 29 is about the central gear 26 is symmetrical to the center; the planetary gear 29 is internally meshed with the ring gear 27 at the same time, and the two ends of the axles of the central gear 26 and the planetary gear 29 are respectively connected in rotation with the tie rod 28 through bearings.

specific Embodiment approach 3

[0021] Specific implementation mode three: as figure 1 , figure 2 As shown, a kind of multi-rotor unmanned aerial vehicle described in the specific embodiment 1 timely adjusts the internal tooth planetary gear train mechanism, and the worm gear is fixed on the internal ring gear 27, and the two can be split, that is, the internal ring gear and the worm gear are The two parts are fixed together by bolts, rivets, welding, jacking screws, keys, or designing a specific structure. At this time, the gear teeth and worm gear teeth may not be on the same plane; they can also be integrated , that is, the inner side of the ring gear is gear teeth, and the outer side is worm gear teeth. At this time, the gear teeth and worm gear teeth may not be on the same plane.

[0022] Working principle: engine 3 (direct drive engine) transmits power to rotor 1 through planetary gear train 2. The rotational speed of the rotor 1 is equal to the synthesis of the rotational speed of the engine 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com