Arch frame installation trolley double-remote-control control system

An arch installation and control system technology, applied in general control systems, control/adjustment systems, program control, etc., can solve the problems of low efficiency of artificial vertical arches, poor construction environment, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

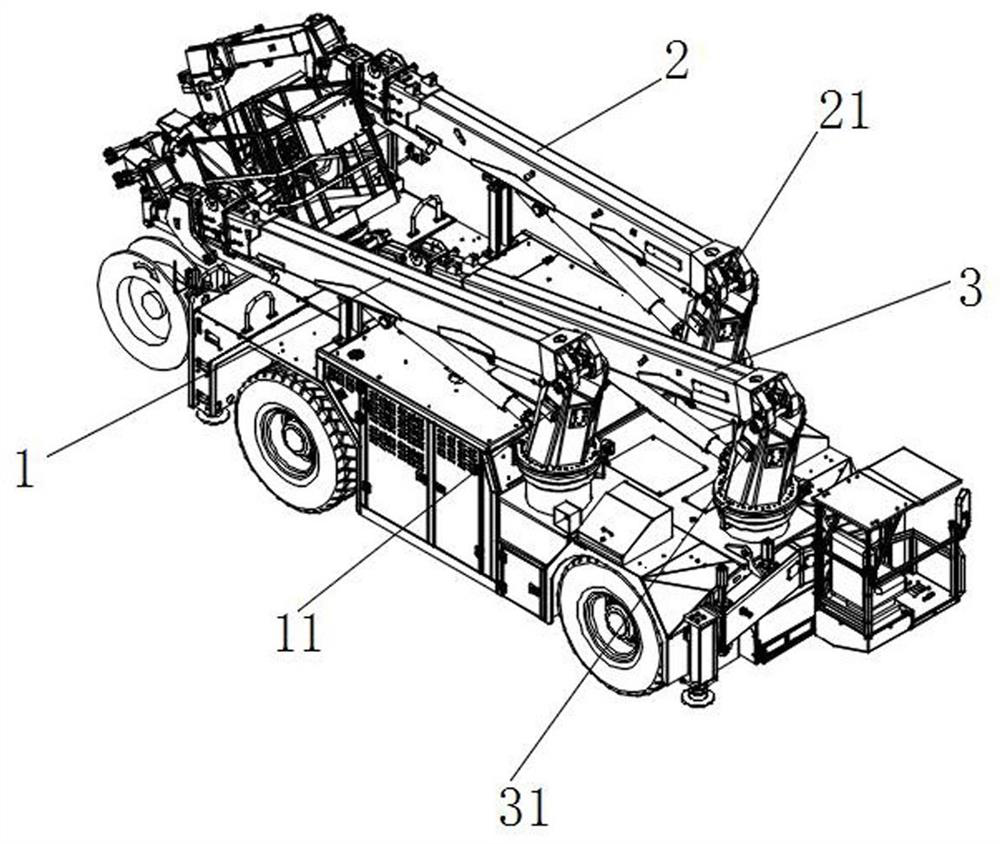

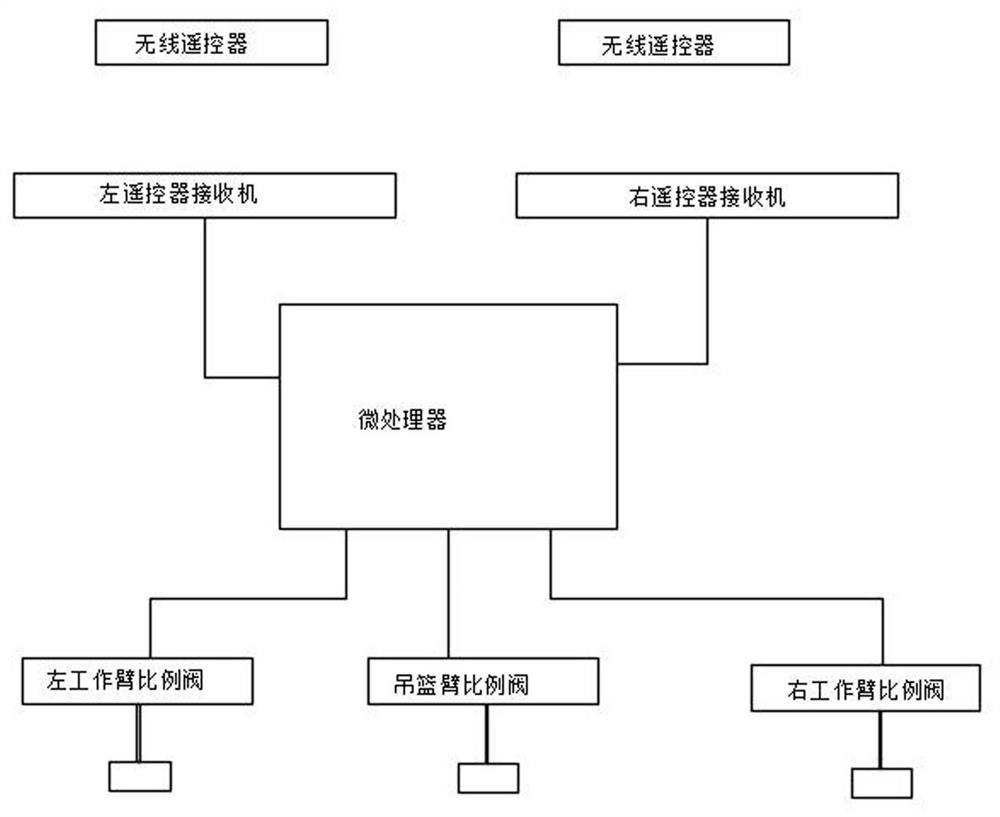

[0024] like figure 1 As shown, the double remote control control system of the arch frame installation trolley of the present invention includes a left remote control receiver, a right remote control receiver, a microcontroller, a left working arm proportional valve 11, and a hanging basket arm installed on the arch frame installation trolley. The proportional valve 31, the right working arm proportional valve 21 and the two remote controllers used to control the arch installation trolley, the output ends of the left remote controller receiver and the right remote controller receiver are respectively connected to the microcontroller through signal lines, and the microcontroller The output end of the controller is respectively connected to the proportional valve 11 of the left working arm, the proportional valve 31 of the hanging basket arm, and the proportional valve 21 of the right working arm through signal lines, and the left remote control receiver can independently control...

Embodiment 2

[0033] Based on Embodiment 1, the left remote controller receiver and / or the right remote controller receiver control the proportional valve 11 of the left working arm, the proportional valve 31 of the hanging basket arm and the proportional valve 21 of the right working arm according to the control instructions issued by the wireless remote controller Execution of independent actions or combination of actions.

Embodiment 3

[0035] Only one remote controller is connected with the right remote controller receiver, and the left working arm proportional valve 11, the hanging basket arm proportional valve 31, and the right working arm proportional valve 21 are controlled by the right remote controller receiver, thereby carrying out the arch installation operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com