Assembly machine offline detection device and detection method

An offline detection and detection device technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem that the assembly machine cannot realize six degrees of freedom movement, the assembly machine cannot realize offline detection, and there is no quality inspection experimental device and other problems, to achieve the effect of convenient processing, production, installation and layout, easy offline detection, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

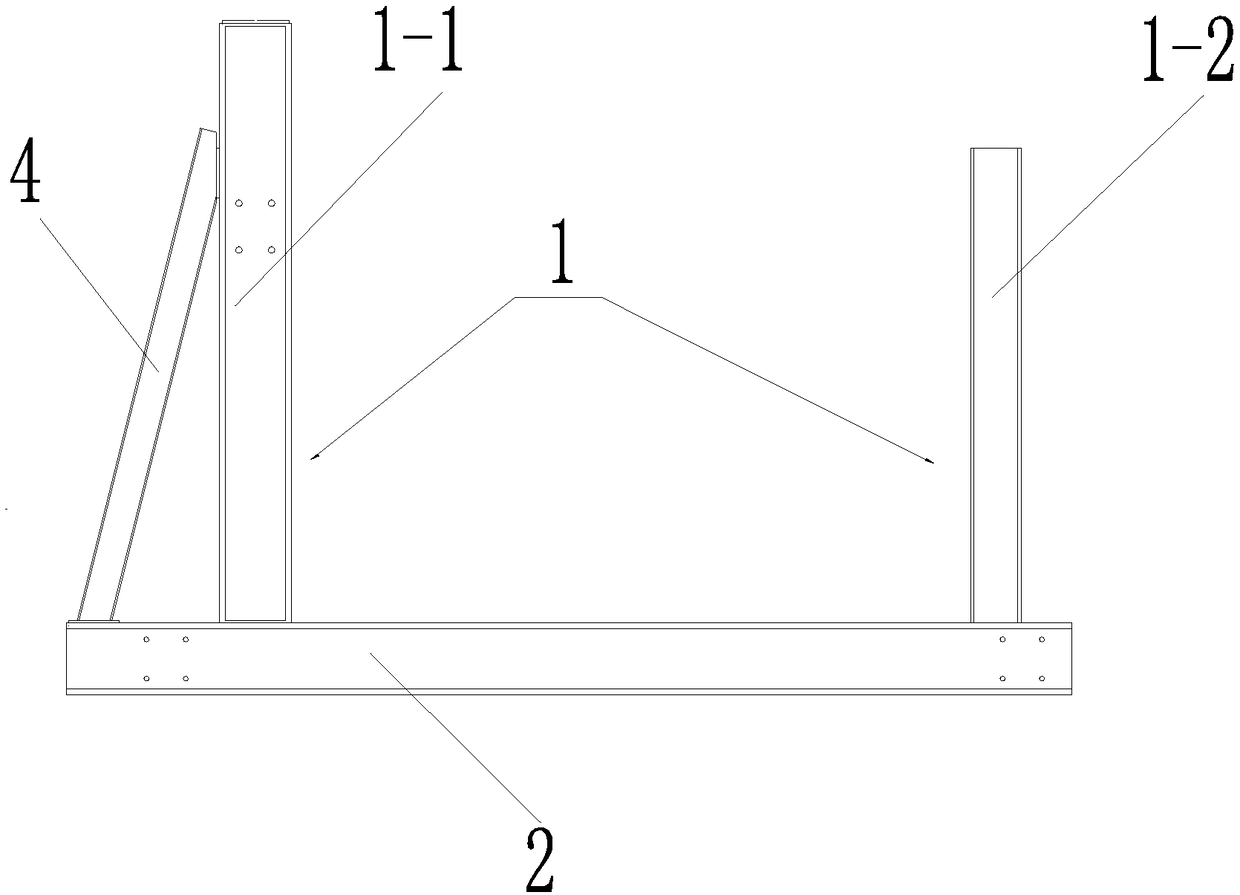

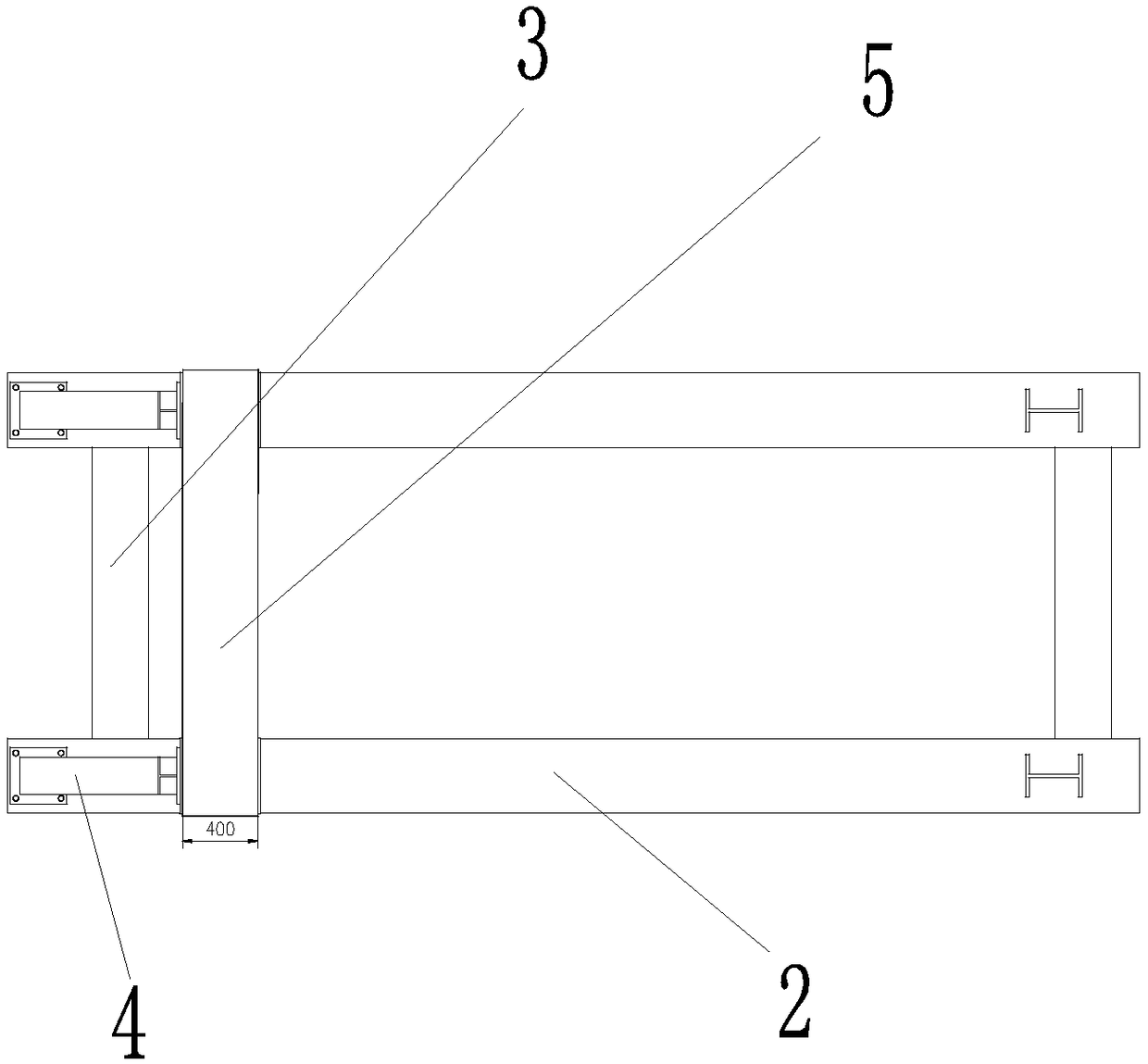

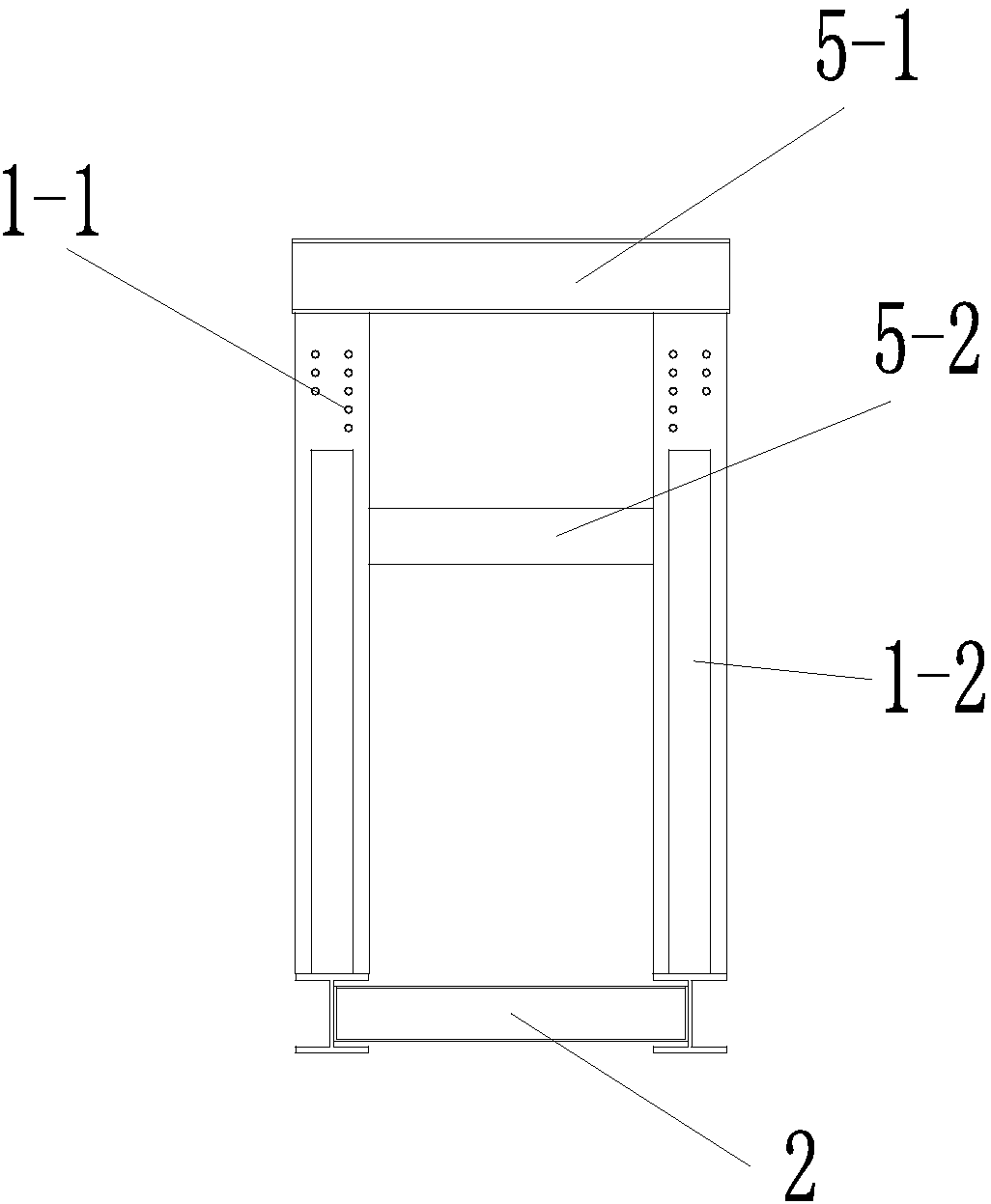

[0052] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes an installation platform for connecting the main beam of the assembly machine and a detection device for detecting the off-line assembly machine. The installation platform includes a vertical beam 1 for connecting the main beam of the assembly machine and a vertical The base at the bottom of the beam 1, the base includes two base beams 2 installed at the bottom of the vertical beam 1 and a base that is respectively arranged at the two ends of the two base beams 2 and is used to connect the two base beams 2 Beam connecting plate 3, the vertical beams 1 are respectively the first group of vertical beams 1-1 close to the side of the base beam 2 and the second group of vertical beams 1-2 close to the other side of the base beam 2, the One end of the base beam 2 is respectively provided with vertical beam oblique support plates 4 connected to the first group of vertical beams 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com