Method for determining reasonable empty-support distance of tunneling head

An empty roof and roadway technology, which is applied in the field of coal mine roadway excavation technology, can solve the problems of difficult selection of mechanical parameters, poor reliability, and large test workload, and achieve the effect of avoiding tediousness, high reliability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

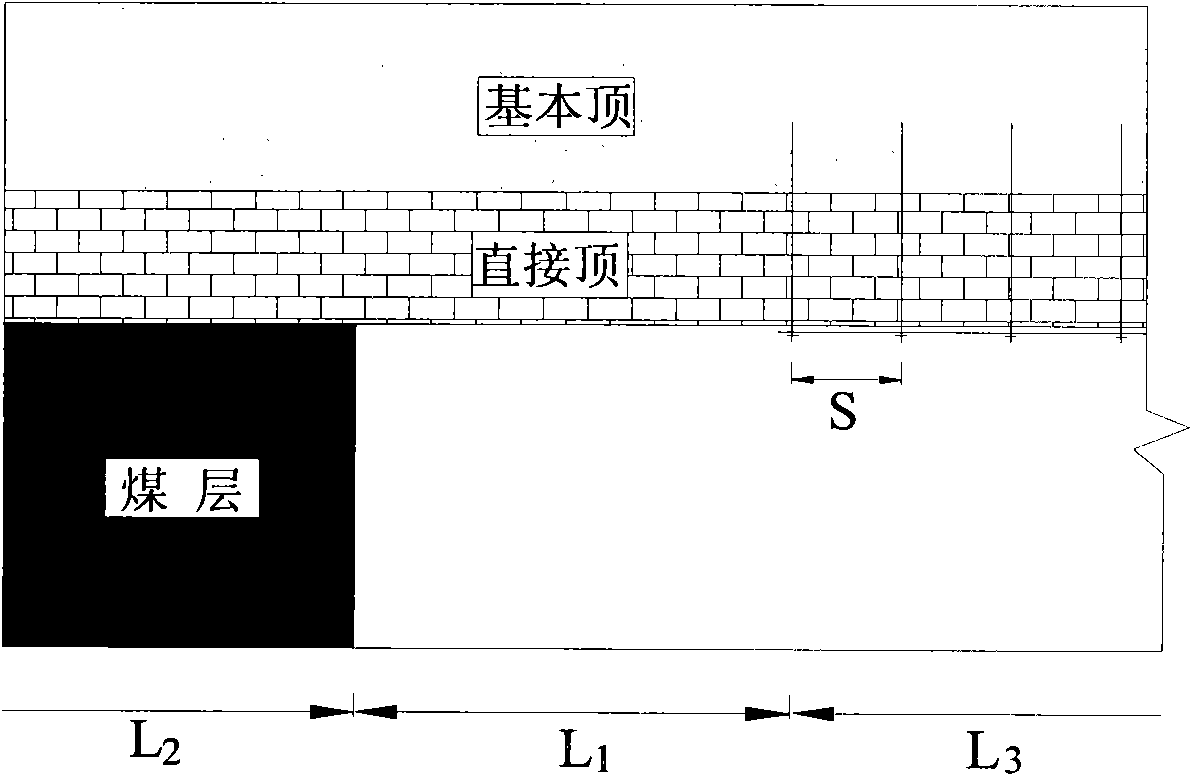

[0020] (1) Sampling the rock directly on top of the roadway to measure its uniaxial compressive strength and tensile strength. The direct roof of the mining roadway in the 9802 working face of a mine is mudstone with a thickness of 2.54m, and the basic roof is medium-fine sandstone with a thickness of 35m. The uniaxial compressive strength and tensile strength of the immediate roof of the mudstone determined by the test are 21.87MPa and 0.9MPa, respectively.

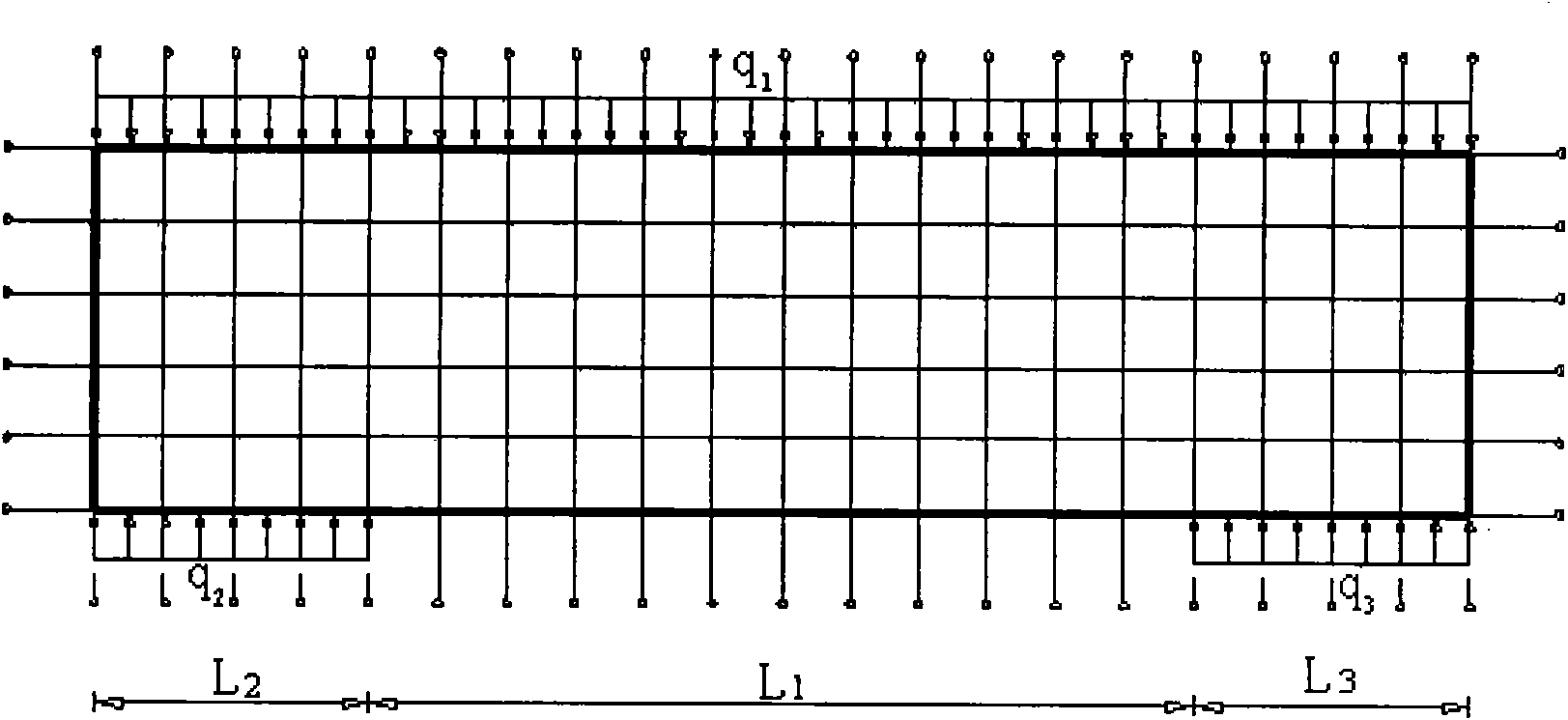

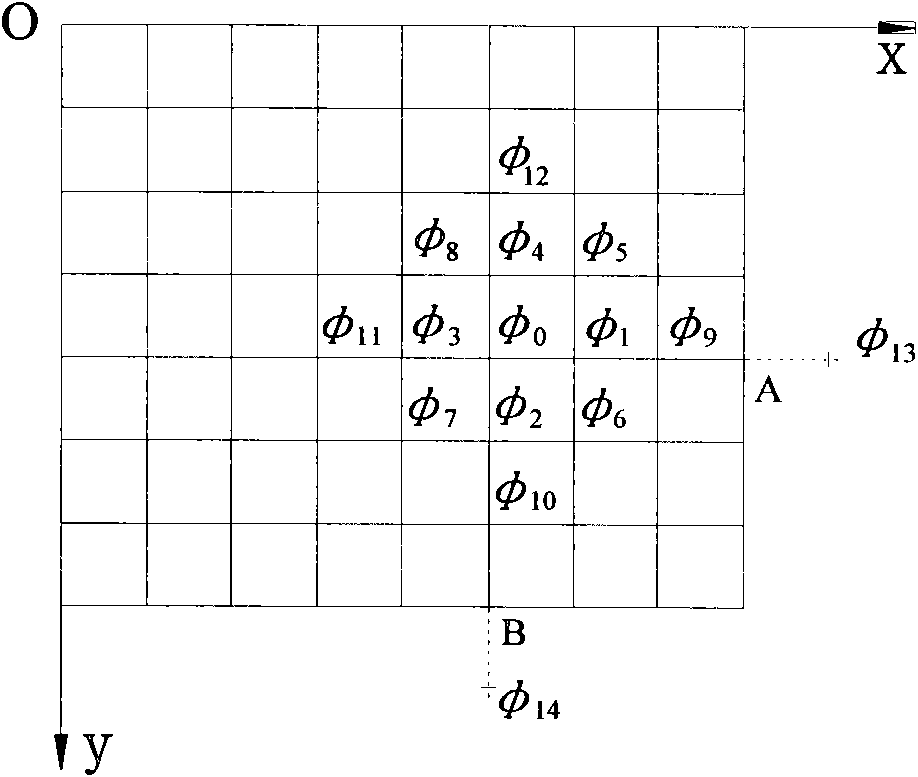

[0021] (2) Carry out the force analysis of the direct roofing of the tunneling head-on roadway, and establish a number of direct roofing mechanical models with an integer number of bolt row spacing S (the distance between two adjacent rows of bolts) as the empty roof distance. 9802 working face back mining roadway bolt row distance S = 1m. The on-site construction found that the stability of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com