Coal-rock drift quick tunnelling method

A coal-rock roadway, rapid technology, applied in the field of coal-rock roadway rapid excavation, can solve the problems of coal-rock mass penetration enhancement, outburst elimination, safety and rapid excavation difficulties, etc., to achieve the effect of suppressing spontaneous combustion, improving the working environment, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

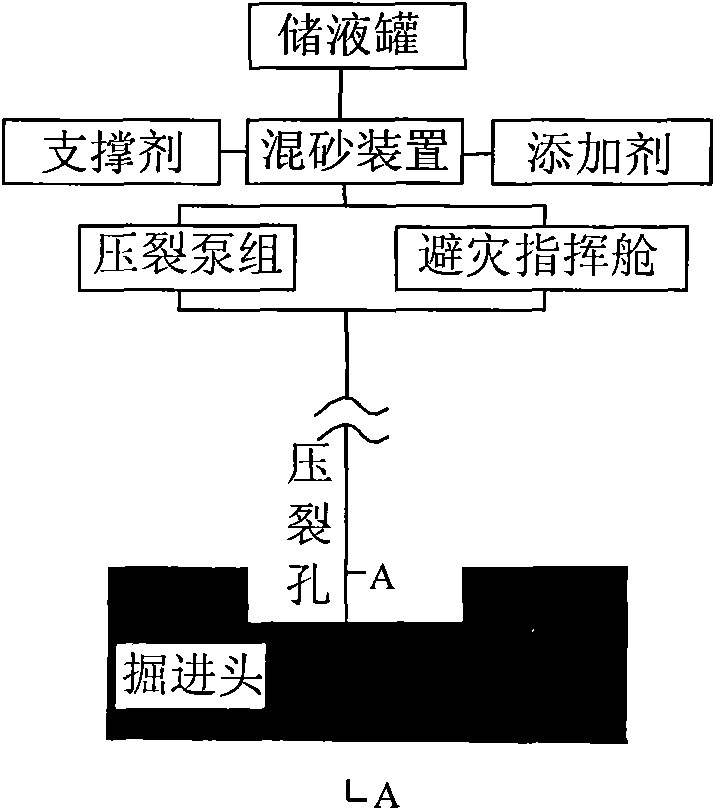

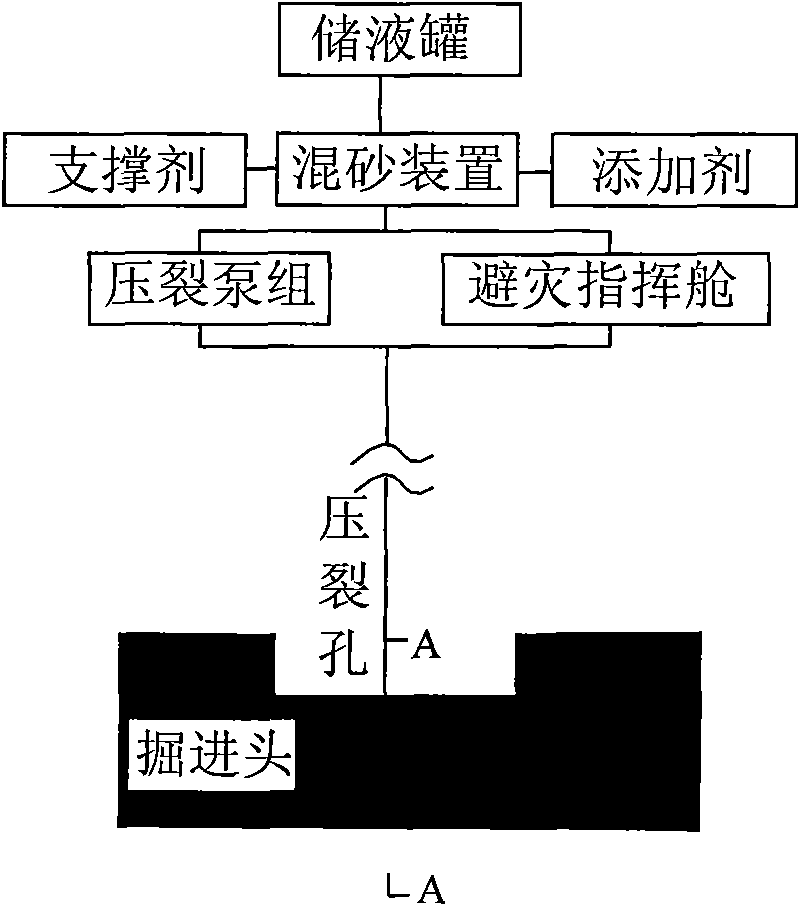

[0014] Such as figure 1 , 2 Shown, the present invention carries out by following steps operation:

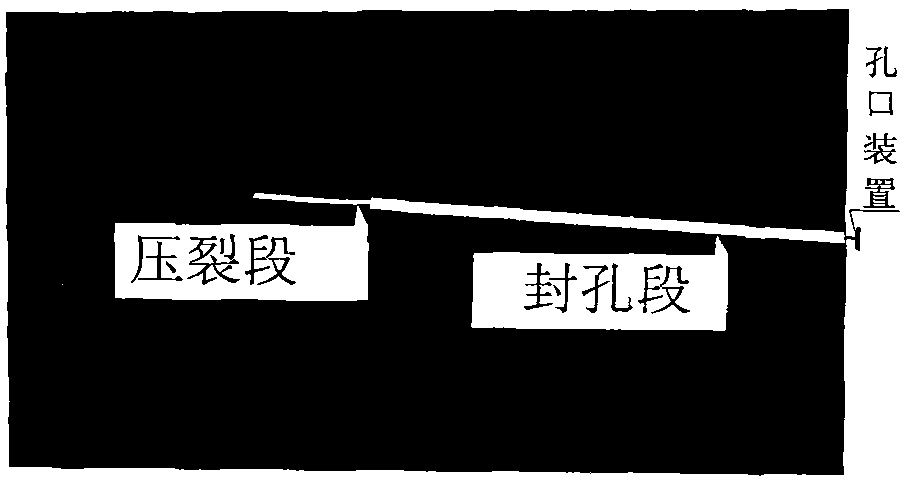

[0015] The first step is to construct long boreholes for fracturing in the front of the excavation. The position of the final hole must pass through the pressure relief area to ensure that there is no geological or pre-exploration boreholes around, and seal the holes with a special sealer for fracturing;

[0016] The second step is to lay high-pressure pipelines, install, arrange and debug fracturing pump sets;

[0017] The third step is to connect the special hole sealer for fracturing through the high-pressure pipeline while ensuring the smooth flow of the high-pressure pipeline;

[0018] The fourth step is to cut off the power, evacuate people, set up a safety warning line, and professional operators start the fracturing pump unit to implement the excavation hydraulic fracturing operation;

[0019] The fifth step is to drain underground, implement drainage holes, and netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com