Full-face fast vertical supporting anchor digging machine

A full-section, bolt-mining technology, applied in the direction of temporary shield, bolt installation, directional drilling, etc., can solve problems such as insufficient improvement in operation efficiency, inconvenience for drivers to get on and off, and easy damage to the device, and achieve low vibration. , Short working time, the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

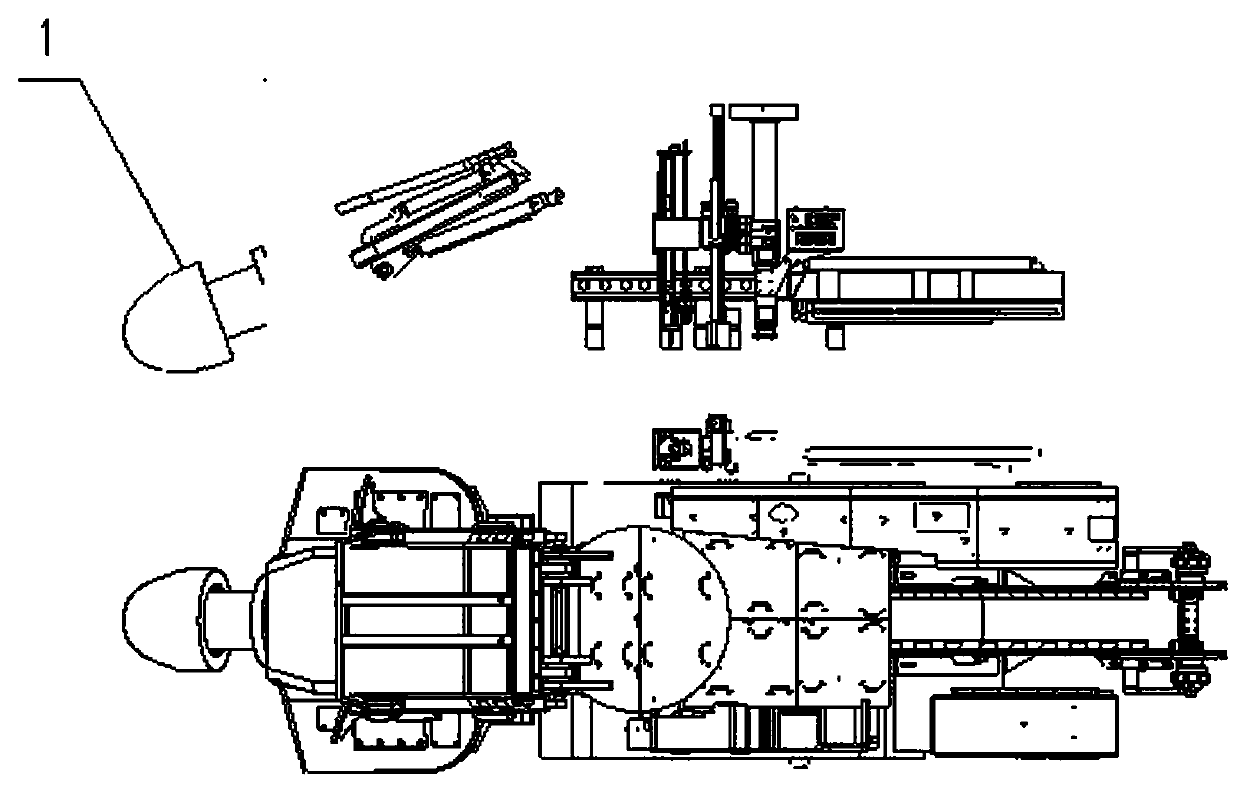

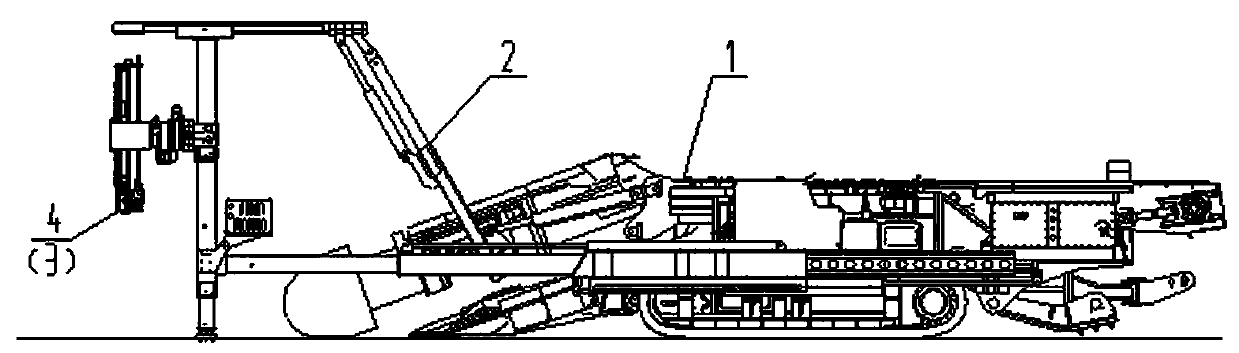

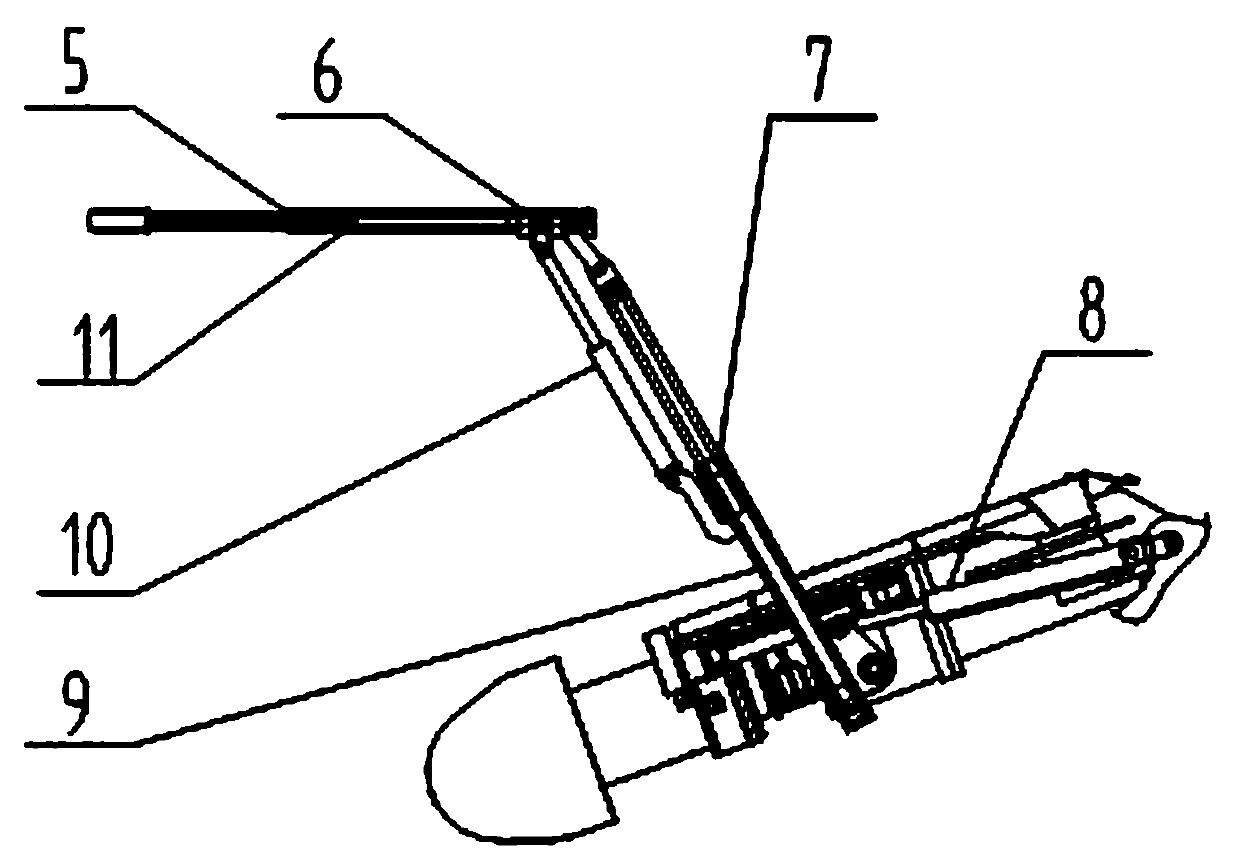

[0043] A full-section fast vertical anchor bolter, such as figure 1 As shown, it mainly includes three parts: cantilever type roadheader (1), temporary support device (2) and left and right bolter devices (4) (3). The temporary support device (2) is installed on the cutting part of the roadheader, folded above the cutting part during excavation, does not affect the driver's line of sight and the excavation performance of the roadheader, and unfolds during support to play the role of temporary support. The left and right rock bolt devices (4) (3) are respectively installed on both sides of the traveling part of the boring machine. Such as figure 2 As shown, during the support operation, the temporary support device (2) is unfolded to hold up the mesh to play the role of netting and temporary support, and the left and right bolter devices (4) (3) are stretched out forward to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com