Rotary pruner

A technology of pruning machine and turning machine, which is applied to electric pruning saws, agricultural machinery and implements, cutting tools, etc., can solve the problems of increased work intensity, poor balance of the whole machine, heavy machine weight, etc., and achieves improved operating comfort. , the effect of good balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments provided by the present invention are described in further detail in conjunction with the accompanying drawings:

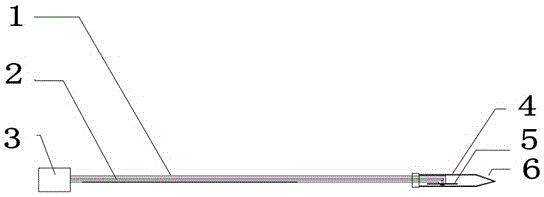

[0009] Such as figure 1 As shown, a rotary pruning machine includes a hollow long-distance rod 1, a rotating shaft 2 is arranged in the long-distance rod 1, a turning machine 3 is provided at one end of the long-distance rod 1, and a protective cover 4 is provided at the other end. The front end of the protective cover 4 is provided with a branch pad 6 , one end of the rotating shaft 2 is connected to the rotating machine 3 , and the other end is connected to the saw disc 5 .

[0010] The pruning machine of the present invention satisfies the working conditions of flat cutting, side cutting and other different arc surfaces through the rotation of the cutting assembly at different angles, and meets the needs of pruning different working planes, and at the same time changes the shearing plane of the cutting assembly through the rotating parts It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com