A device and method for detecting instantaneous torque of a rotating shaft

A detection device, instantaneous torque technology, applied in measurement devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of limited application environment, strong magnetic interference of motors, low detection frequency, etc., to overcome low measurement sensitivity , Improve anti-interference ability, measure the effect of frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

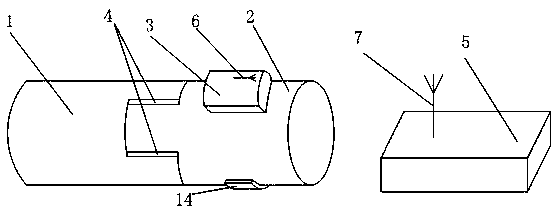

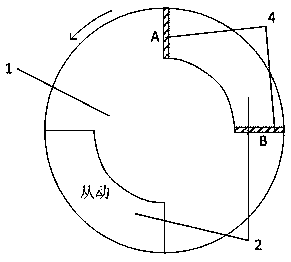

[0020] like figure 1 As shown, the mechanical connection of the rotating shaft in the transmission system adopts the existing elastic plum blossom coupling structure. The elastic plum blossom coupling structure is composed of the driving shaft 1 and the driven shaft 2. The driving shaft 1 and the driven shaft 2 are axially Nested with each other, the driven shaft 1 drives the driven shaft 2 to rotate.

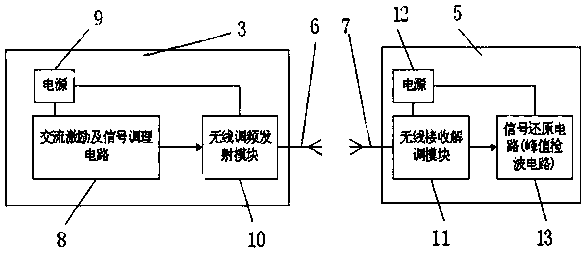

[0021] A rotating shaft instantaneous torque detection device according to the present invention is composed of a follower part and a fixed part 5. The follower part is composed of a stress sensor 4, a follower circuit board 3 and a counterweight 14. The follower part is installed on the rotating shaft. As the rotating shaft rotates, the fixed part is not in contact with the rotating shaft, and signals are transmitted wirelessly between the fixed part 5 and the driven part.

[0022] When the driving shaft 1 and the driven shaft 2 rotate, the stress sensor 4 is fixed and embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com