Main driving device of angle adjustable shield tunneling machine

A shield machine, adjustable technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of increased angle between the shield body and the segment, insufficient weight, damage to the assembled segments, etc., to simplify the cutter head Structure, the effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

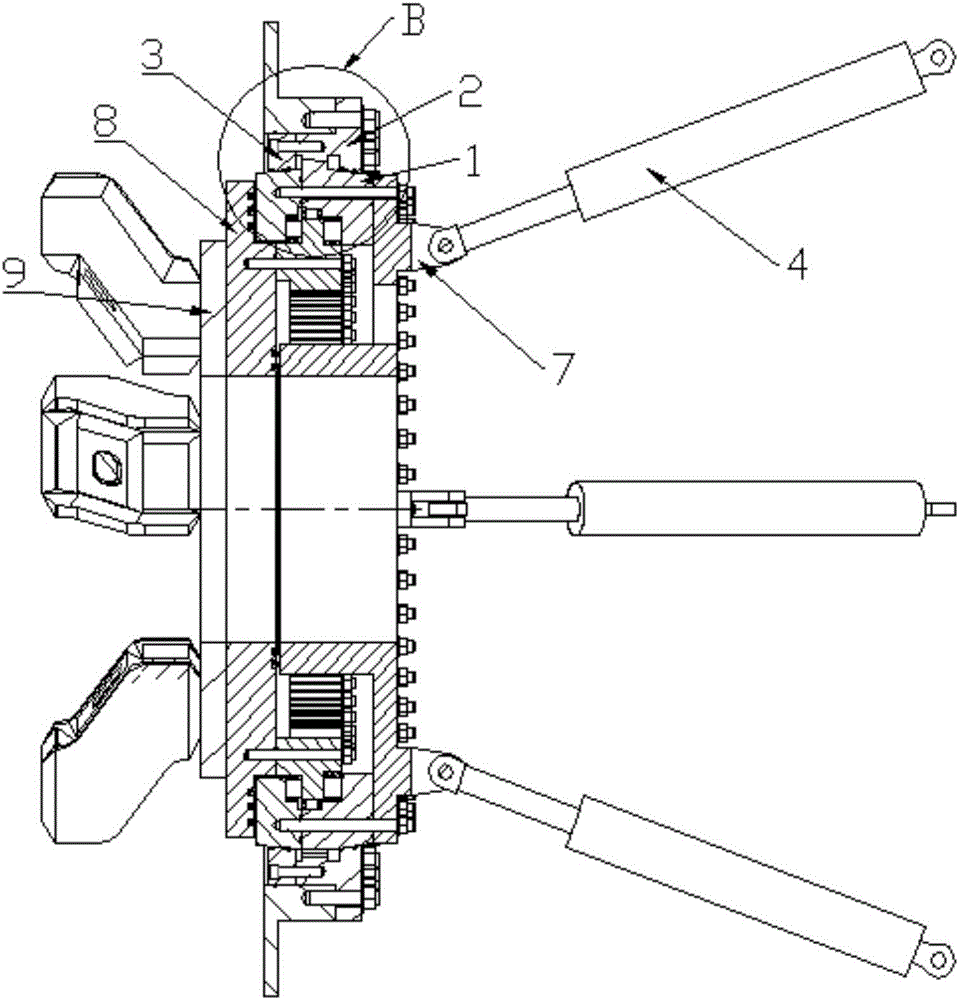

[0026] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

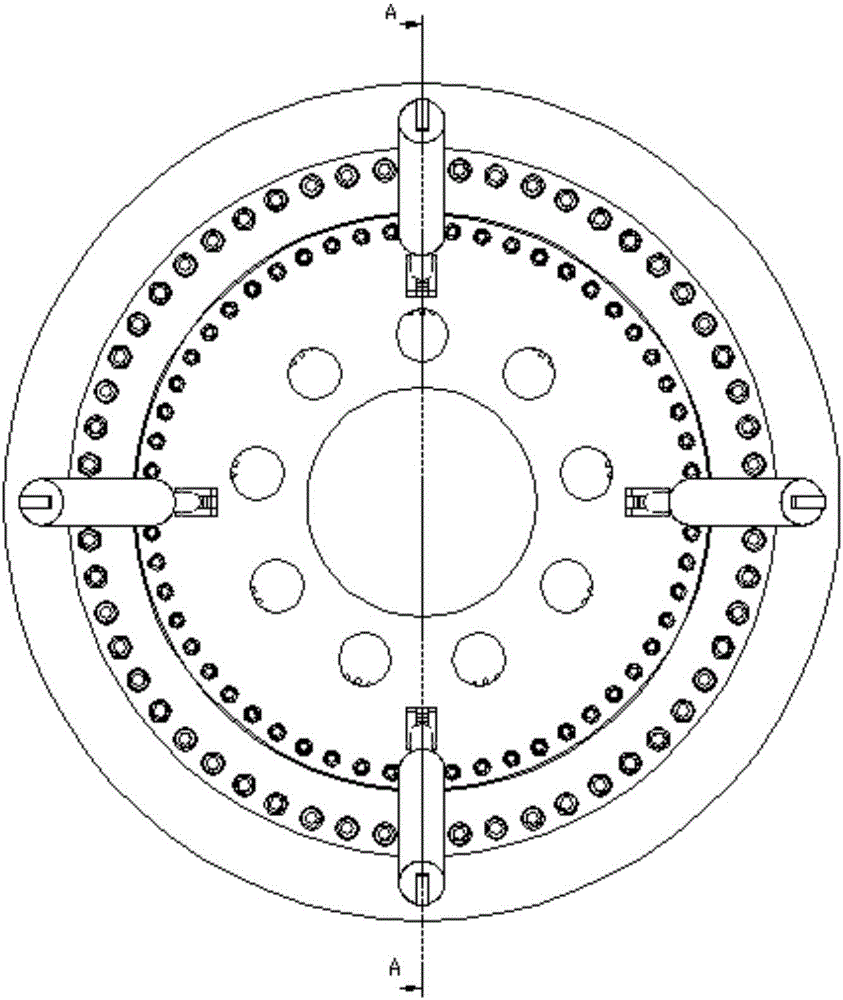

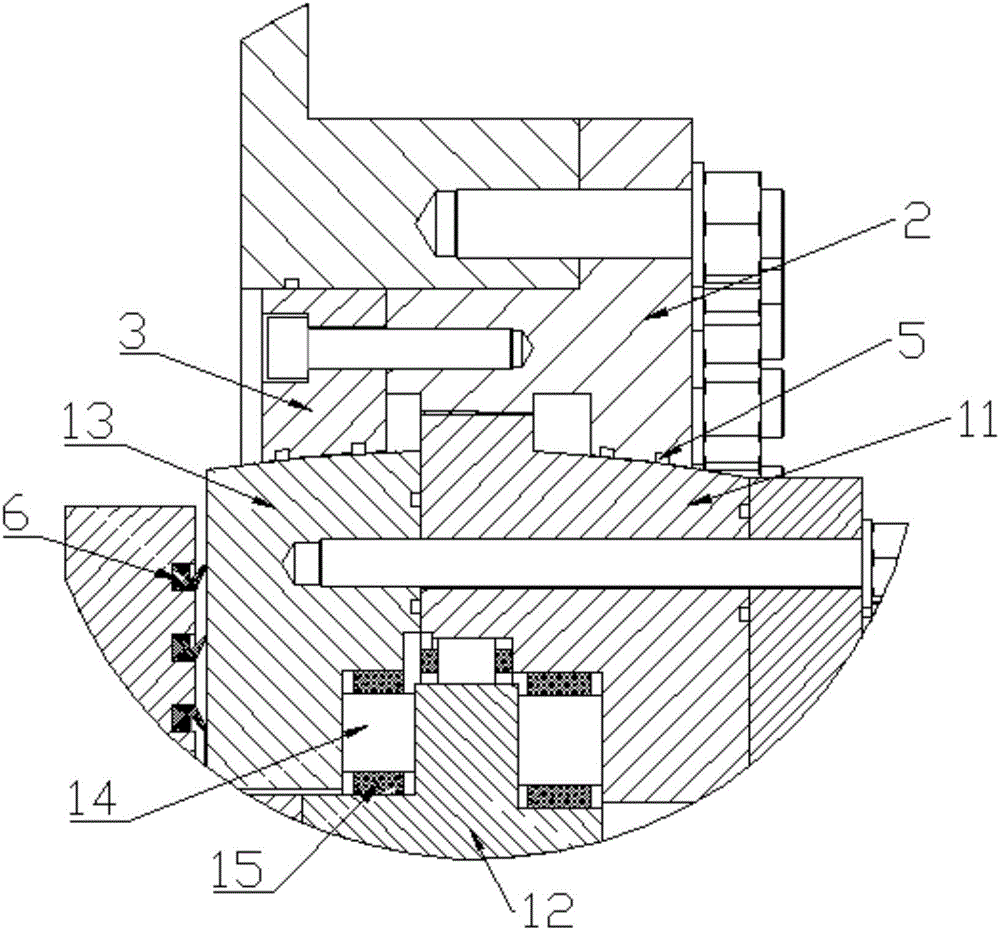

[0027] A main driving device of an angle-adjustable shield machine, including an outer spherical main bearing 1, an inner spherical main bearing mounting seat 2, an inner spherical main bearing mounting seat 3, an angle adjustment oil cylinder 4, an O-shaped sealing ring 5, and an end face sealing ring 6 , oil cylinder mount 7, seal mount 8.

[0028] The outer spherical main bearing 1 is a three-row cylindrical roller bearing for the main drive slewing support, which is composed of a bearing base 11, a bearing ring gear 12, a bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com