Roadway roof fracturing and outburst prevention method

A roadway roof and fracturing technology, which is applied in the direction of drilling equipment and methods, earthwork drilling, mining fluids, etc., can solve the problems of slow roadway excavation speed, large roadway excavation interference, and large number of wells required to improve Coal mining efficiency, avoiding water lock effect, and good diffusibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

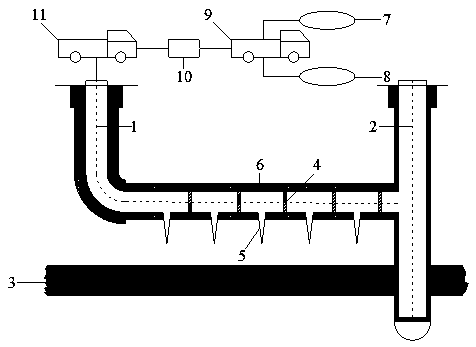

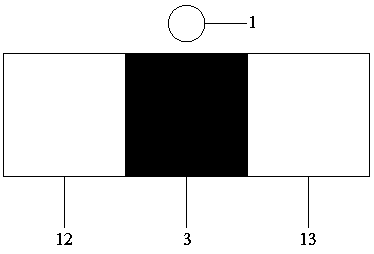

[0025] figure 1 It is a structural schematic diagram of cracking and outburst prevention on the roof of the roadway. figure 1 The structure description is as follows:

[0026] Drill a horizontal well 1 from the ground directly above the reserved coal pillar 3 along the roadway excavation direction, drill a drainage and production vertical well 2 directly above the reserved coal pillar 3 from the ground, and create holes for the drainage and production vertical shaft 2 at the preset level of the horizontal well 1 , so as to facilitate subsequent connection with the horizontal well 1; the heating rod 6 in the well is arranged between the wellbore and the casing of the horizontal well, and the isolation bridge plug 4 is provided in sections in the horizontal well; Hole 5 (the perforation is not connected to the coal pillar); the surface is equipped with supercritical CO 2 Injection device: CO in liquid storage tank 8 2 The plate fragments in the proppant storage tank 7 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com