Self-moving belt conveyor tail

A self-moving, belt-based technology, which is applied in the directions of earth drilling, transportation and packaging, underground transportation, etc., can solve the problems of restricting production efficiency and benefits, tilting of the head of the reloading machine, and slow speed, so as to reduce the number of demolition times and solve the problem of The effect of belt deviation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

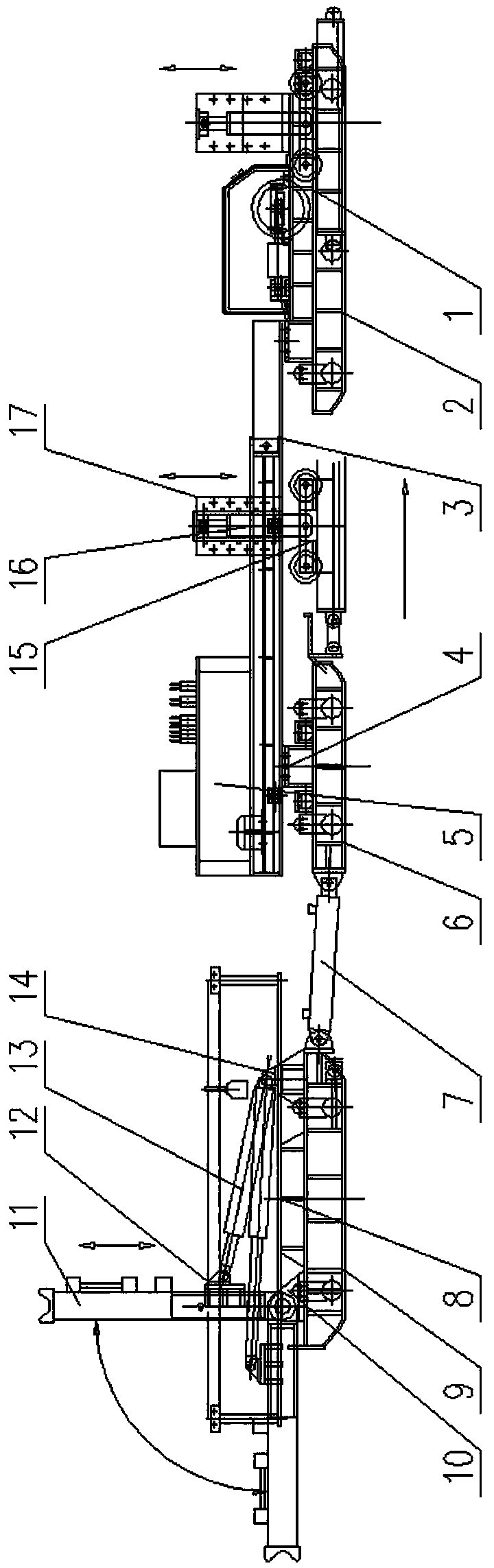

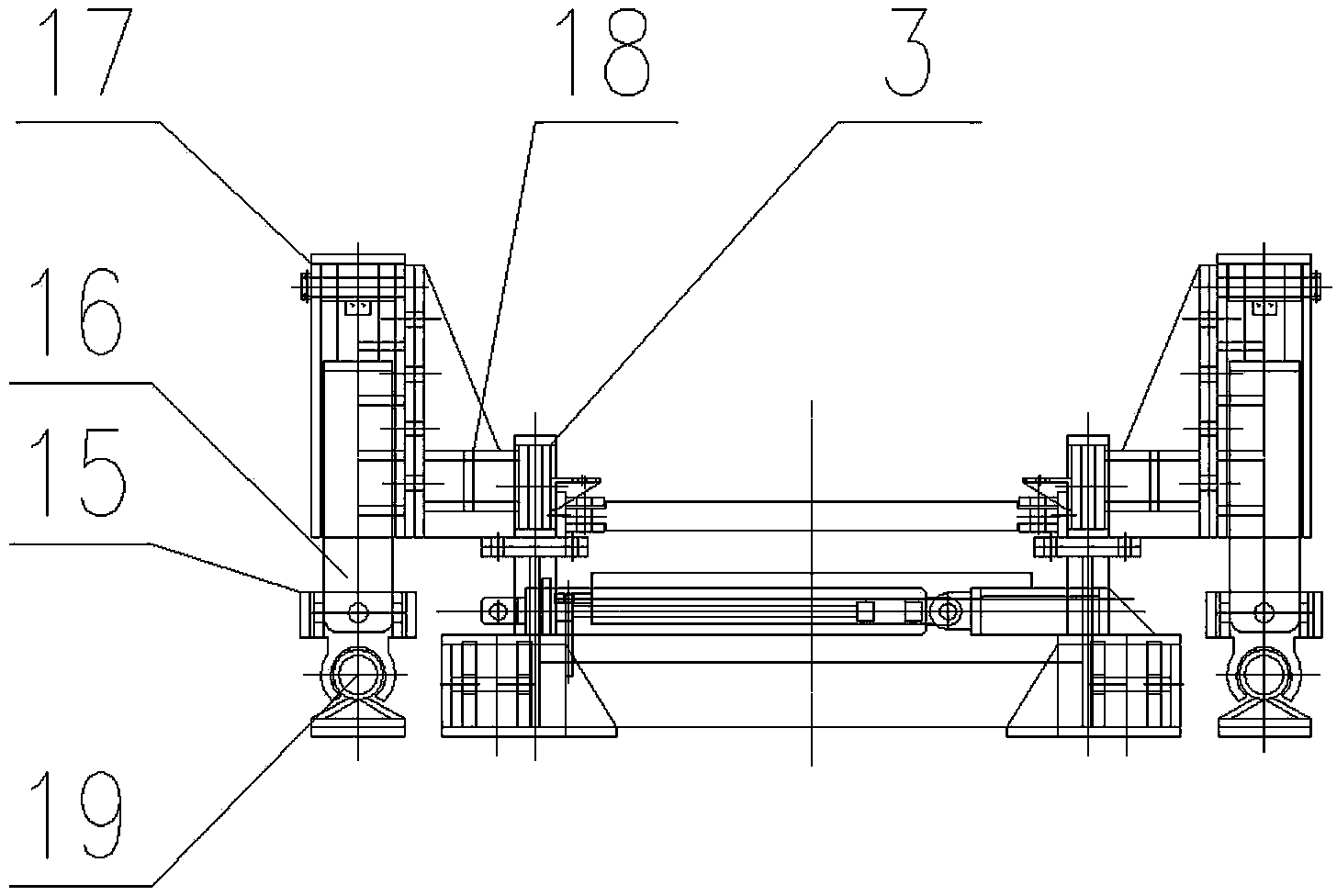

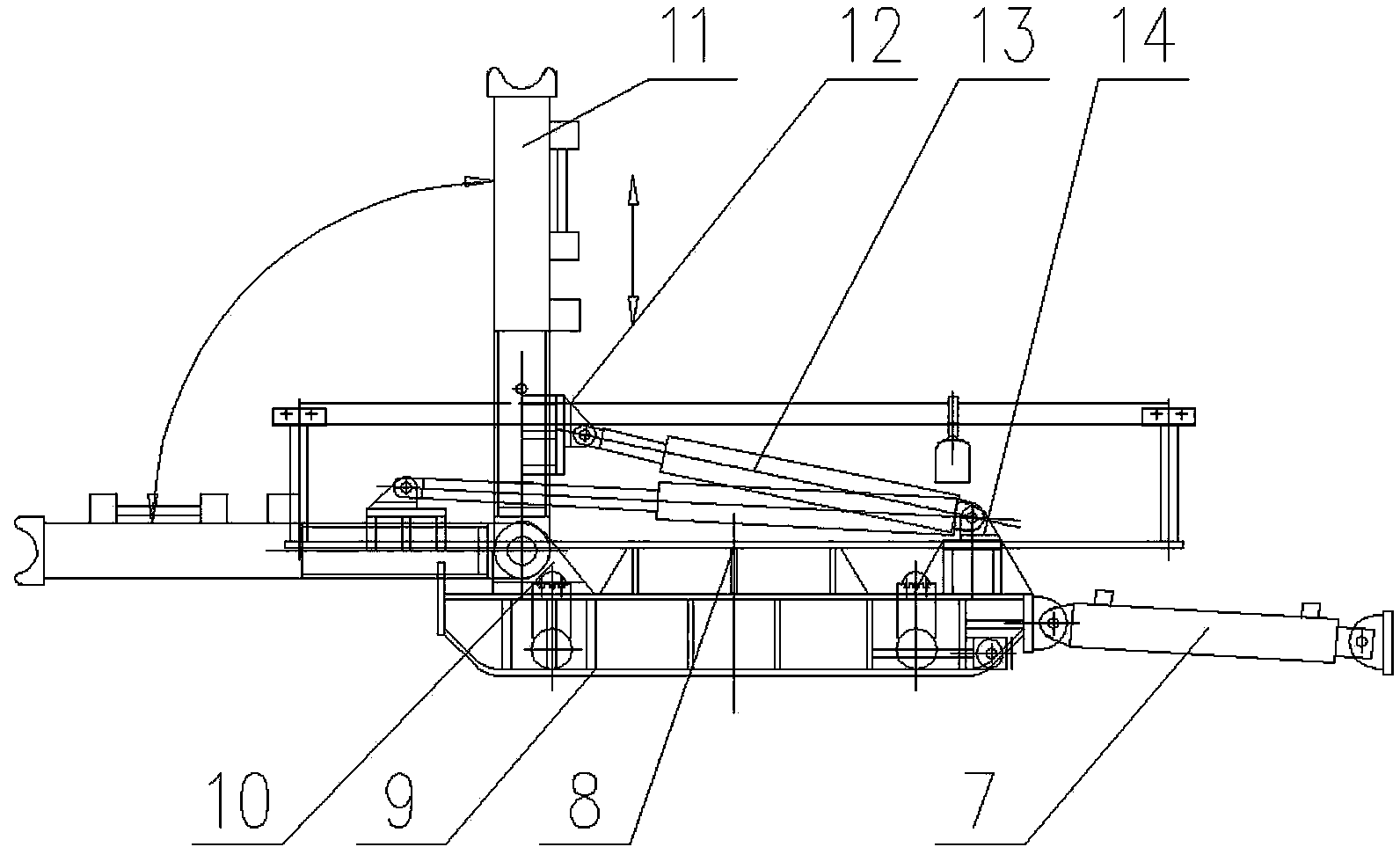

[0024] The present invention comprises machine tail 1, middle part 4, driving part 8, hydraulic system 5, also includes pushing oil cylinder 7, and one end of pushing oil cylinder 7 is hinged with the base 9 of driving part, and the other end is hinged with middle part base 6, and middle part base 6 The beam 3 installed on the top is connected with the tail base 2; it also includes rails, the rails are located on both sides of the tail 1 and the middle part 4, and the rear end is connected with the base 9 of the driving part; the middle part 4 and the tail 1 are installed There is a lifting mechanism, and the lifting mechanism is composed of a two-way walking guide wheel frame 15, a lifting cylinder 16, a lifting cylinder frame 17, and a support frame 18. The two-way walking guide wheel frame 15 is installed on the track 19, and the bottom of the lifting cylinder 16 is hinged on the two-way walking guide wheel On the frame 15, the piston rod of the lift cylinder 16 is hinged wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com