Stirring pile-permeable concrete pile compound foundation and treatment method thereof

A technology for concrete piles and composite foundations, which can be used in sheet pile walls, soil protection, infrastructure engineering, etc., and can solve problems such as low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Cement mixing pile-permeable concrete pile composite foundation

[0053] As shown in Figure 5(a) and Figure 5(b), the cement mixing pile-permeable concrete pile composite foundation pile body is arranged in a square or a triangle, and the cement mixing pile and the permeable concrete pile are arranged in separate rows. Lay a gravel cushion on the foundation surface with a thickness of 15-30cm. The pile distance between every two piles in each row of mixing piles or permeable concrete piles is 3-4 times the diameter of the permeable concrete piles. The diameter of the permeable concrete pile is 0.8-1.0 times the diameter of the mixing pile.

[0054] During construction, the permeable concrete pipe piles shall be constructed first, and then the cement mixing piles shall be constructed, with an interval of not less than 10 days. The verticality error of all piles shall not be greater than 1%.

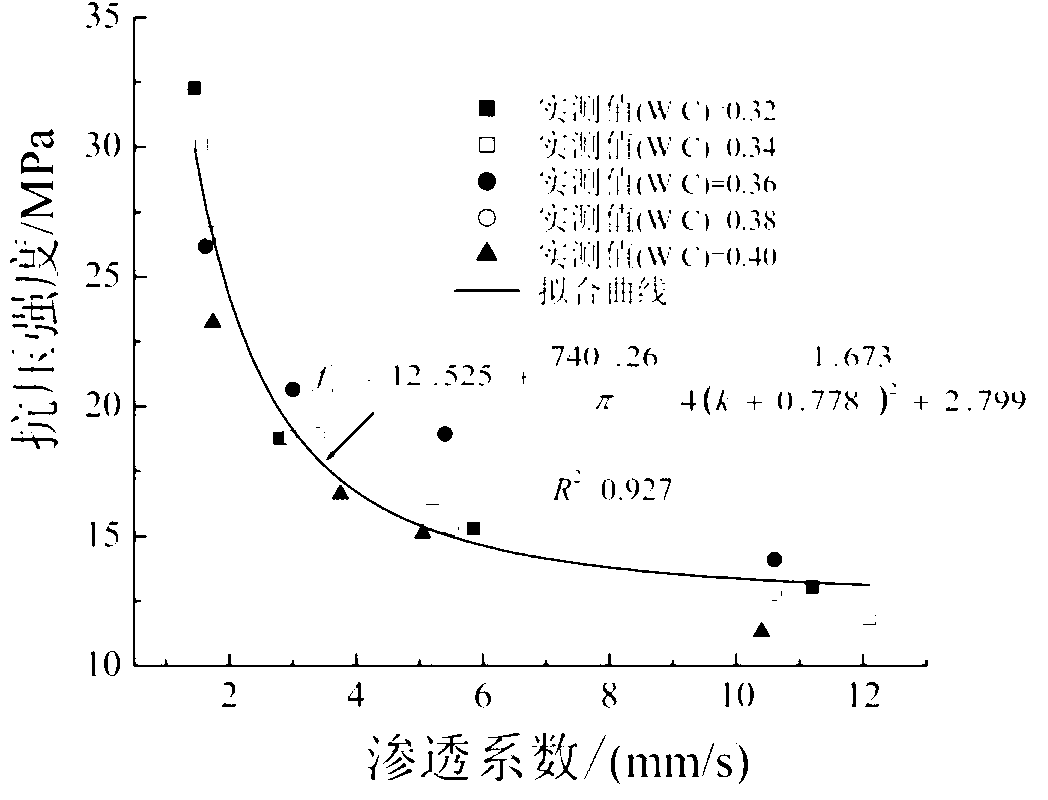

[0055] The design compressive strength of permeable concrete is 2...

Embodiment 2

[0057] Example 2: Lime mixing pile-permeable concrete pile composite foundation

[0058] As shown in Figure 5(a) and Figure 5(b), the lime mixing pile-permeable concrete pile composite foundation pile body is arranged in a square or triangle, and the lime mixing pile and the permeable concrete pile are arranged in separate rows. Lay a gravel cushion on the foundation surface with a thickness of 15-30cm. The pile distance between every two piles in each row of mixing piles or permeable concrete piles is 3-4 times the diameter of the permeable concrete piles. The diameter of the permeable concrete pile is 0.8-1.0 times the diameter of the mixing pile.

[0059] During construction, the permeable concrete pipe pile shall be constructed first, and then the lime mixing pile shall be constructed, and the interval shall not be less than 10 days. The verticality error of all piles shall not be greater than 1%.

[0060] The compressive strength of permeable concrete is 20MPa, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com