Preparation process of metal aluminium template for assembling nano-micron array material

A template and array technology, applied in the field of metal template preparation, can solve problems such as poor mechanical strength, poor toughness of alumina, and difficulties in porous alumina templates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

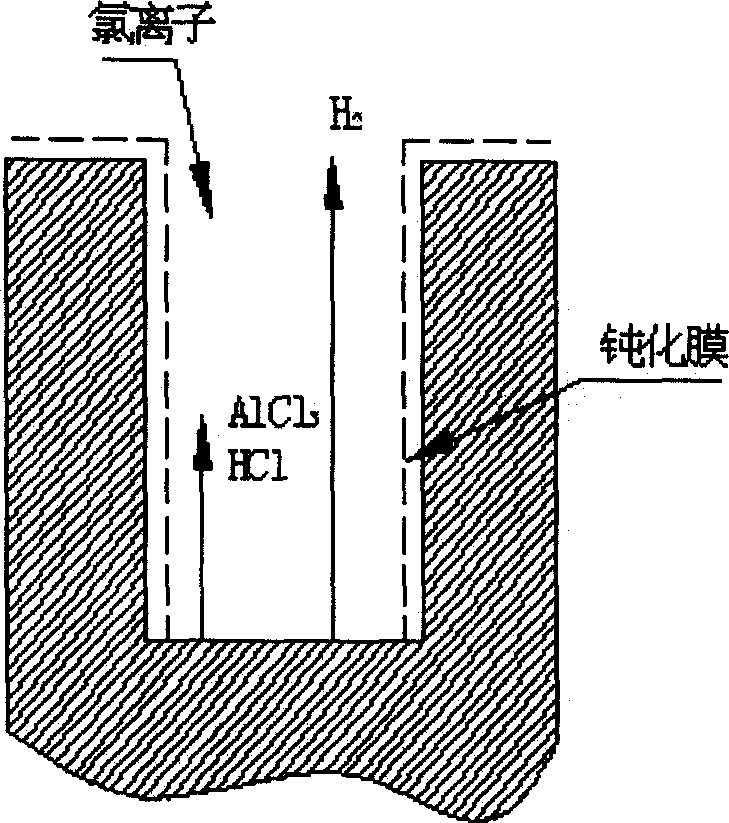

Problems solved by technology

Method used

Image

Examples

Embodiment 1

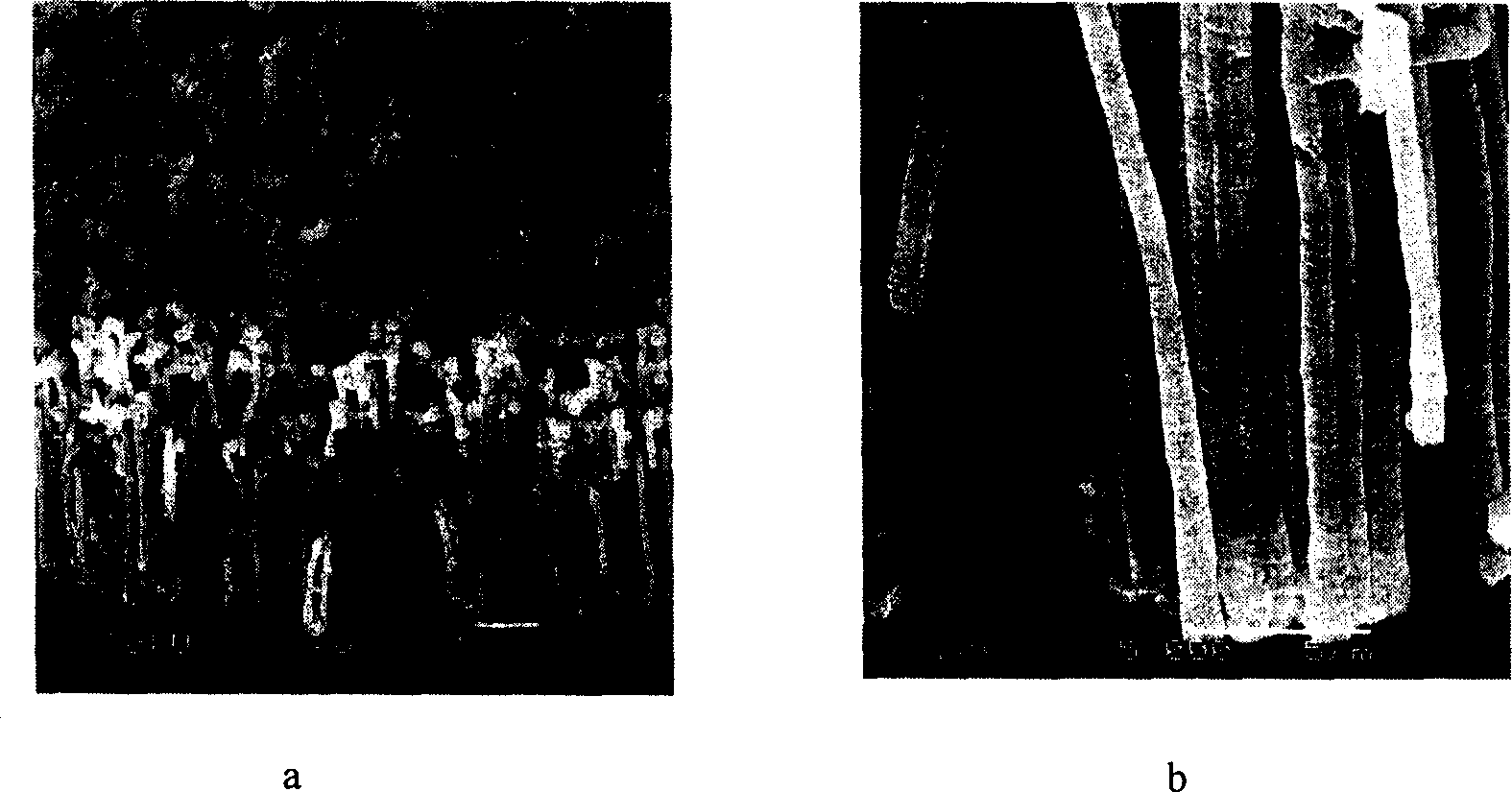

[0033] Example 1: Put the high purity aluminum foil at 0.5mol·L -1 Pretreated in NaOH solution for 20s, the treated aluminum foil is used as the anode, and the chloride ion concentration in the electrolyte is 0.5 mol·L -1 , The acid concentration is 3.0mol·L -1 , The electrolytic etching time is 120 seconds, the etching temperature is 70℃, and the current density applied to the aluminum foil is 1.5×10 4 A / m 2 . After the etching is over, the aluminum foil is washed with clean water, the washing is over, and it is dried.

[0034] The operation steps of other examples are as described in Example 1, and the process conditions of Example 2 to Example 6 are shown in Table 1.

[0035]

Condition

Pretreatment

Time

s

mol·L -1

Concentration

mol·L -1

Etch

Time

s

10 4 A·m -2

Etch

Temperature

°C

Aperture adjustment

Festival time

min

Template

Trai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com