Magnetic alloy serving as magnetic refrigeration material

A technology of magnetic refrigeration materials and magnetic alloys, applied in the field of magnetic alloys, can solve problems such as difficult operation, obstacles to the ideal and practical working medium of magnetic refrigeration materials, and large and complex refrigeration systems, and achieve the effects of easy control, abundant reserves, and huge magnetocaloric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

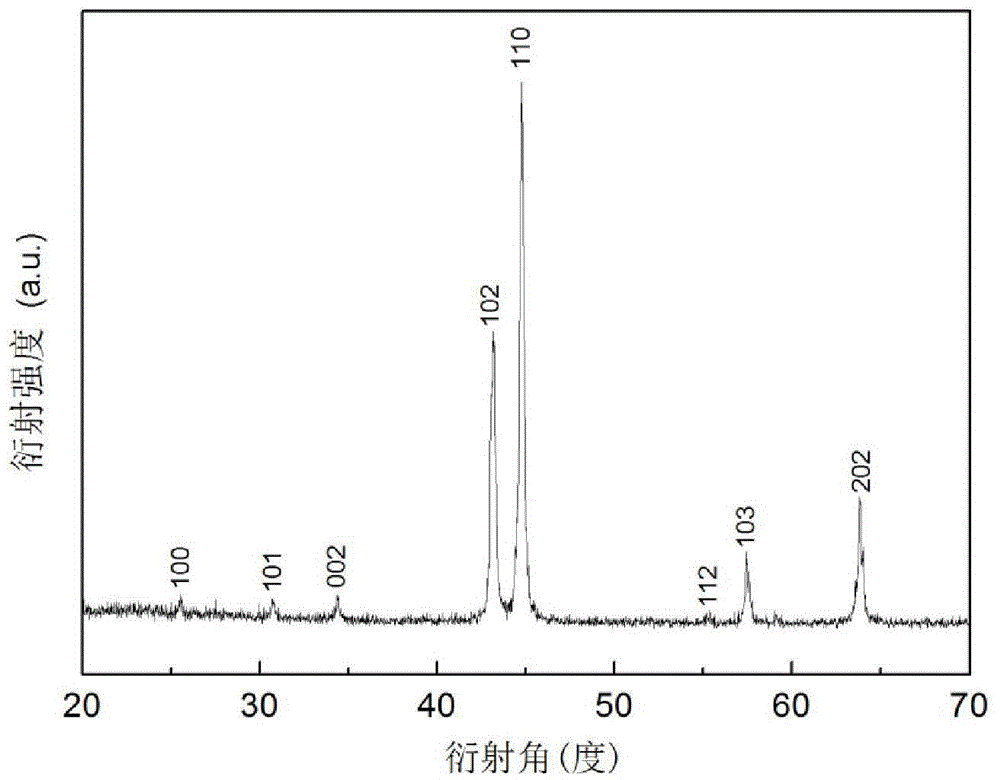

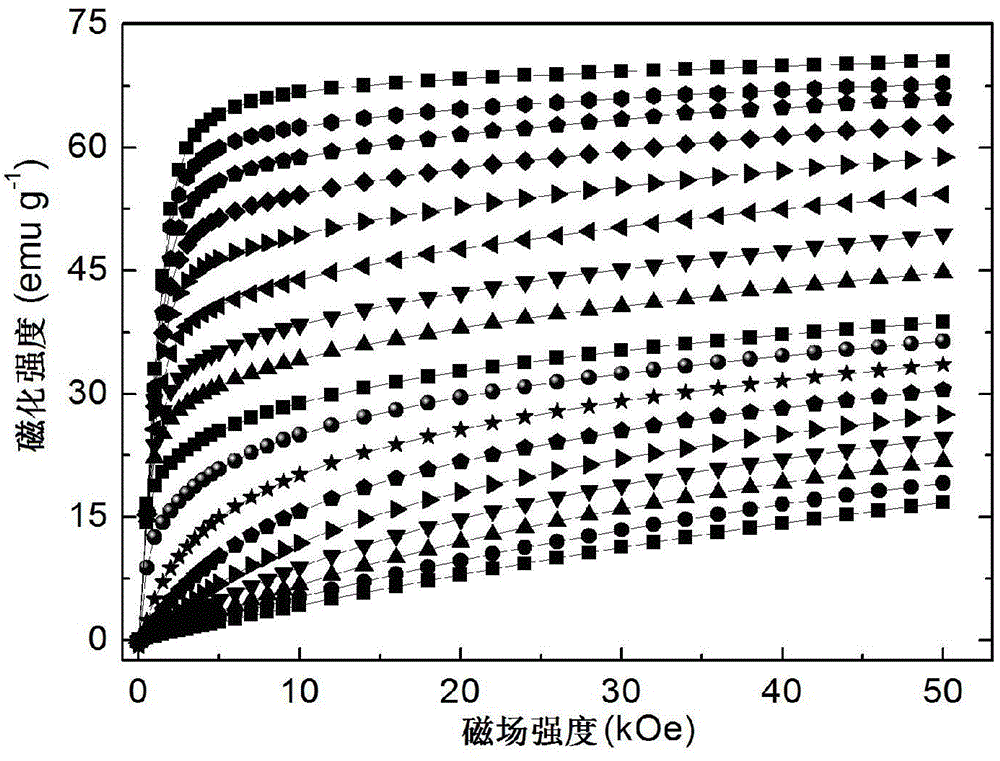

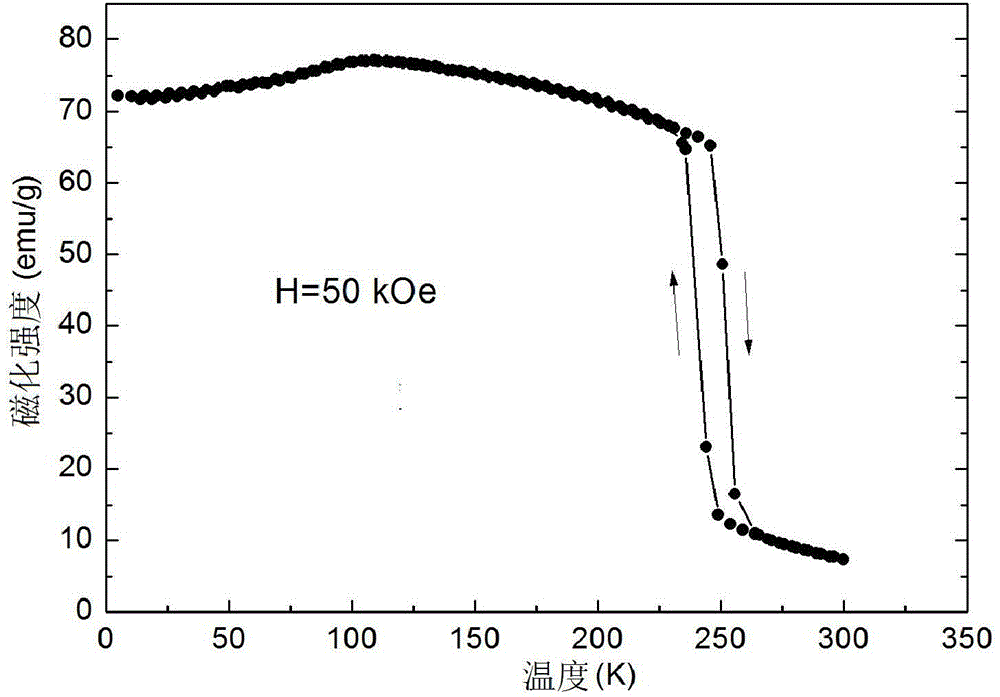

[0025] The preparation composition of this embodiment is Mn 30 co 3 Ni 30 Ge 37 The subscripts of each element represent the atomic number percentage content of the corresponding element in the alloy. For example, Mn 30 co 3 Ni 30 Ge 37 The alloy means that the alloy contains 30 atomic percent of Mn element, 3 atomic percent of Co element, 30 atomic percent of Ni element and 37 atomic percent of Ge element. In other embodiments, the same explanation is also made.

[0026] Step 1.1: According to the molar ratio of Mn:Co:Ni:Ge=30:3:30:37, respectively weigh Mn, Co, Ni, Ge metal raw materials with a purity of 99.9%;

[0027] Step 1.2: Put the weighed raw materials into the crucible, and use a mechanical pump to evacuate the vacuum to 2×10 -3 Below Pa, argon gas is introduced as a protective gas, the polycrystalline sample ingot is melted by arc melting method, the melting current is 100A, each sample is turned 3 times, and smelted 4 times in total to ensure uniform compo...

Embodiment 2

[0031] The composition of the preparation is Mn 23 co 10 Ni32 Ge 35 Magnetic Alloy Strip:

[0032] Step 2.1: According to the molar ratio of Mn:Co:Ni:Ge=23:10:32:35, respectively weigh Mn, Co, Ni, Ge metal raw materials with a purity of 99.9%;

[0033] Step 2.2: Put the weighed raw materials into the crucible, and use a mechanical pump to pump the vacuum to 2×10 -3 Below Pa, argon gas is introduced as a protective gas, the polycrystalline sample ingot is melted by arc melting method, the melting current is 100A, each sample is turned 3 times, and smelted 4 times in total to ensure uniform composition;

[0034] Step 2.3: The obtained button spindle material is sealed in a vacuum quartz tube, annealed at 850°C for 120 hours for homogenization annealing treatment, and then cooled to room temperature at a cooling rate of 2°C / s;

[0035] Step 2.4: Put the annealed button ingot into a quartz tube with a small hole at the bottom, place it in the furnace cavity of the belt throwin...

Embodiment 3

[0037] The composition of the preparation is Mn 24 co 6 Ni 37 Ge 33 Magnetic alloy: except that the molar ratio of the constituent elements is Mn:Co:Ni:Ge=24:6:37:33, and the annealing temperature of the sample is 900°C, and the annealing time is 96 hours, the rest of the steps are the same as in Example 1. The phase transition temperature and magnetic entropy change values of the samples are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com