Magnesium-strontium-rare earth interalloy and preparation method thereof

A rare earth intermediate alloy and rare earth technology, which is applied in the fields of metal materials and metallurgy, can solve the problems of complex preparation process, toxic cost, and reduce the corrosion resistance of magnesium alloys, and achieves obvious grain refinement, stable metamorphism effect, and improved ignition point. with antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

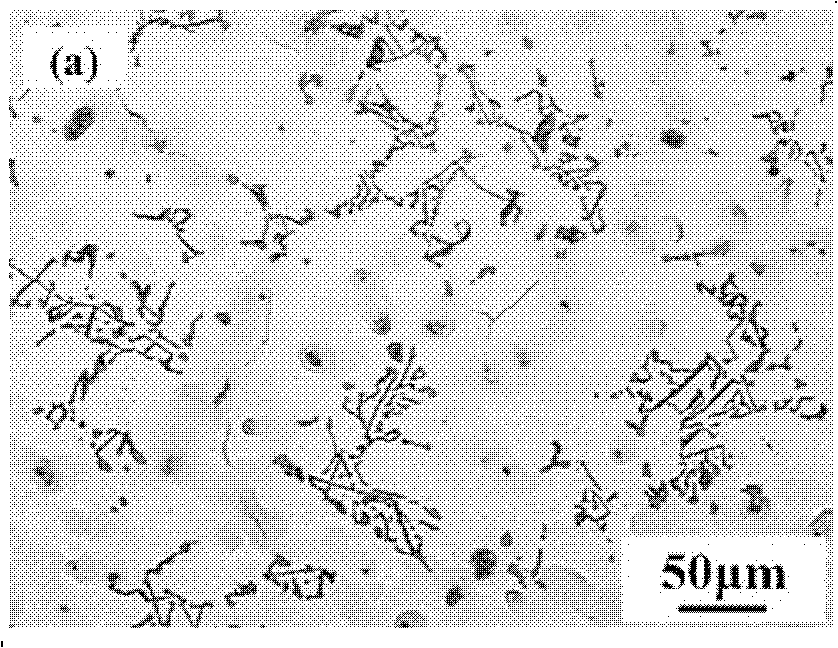

[0033] (1) Firstly, raw materials are weighed by weight percentage: 70% of pure magnesium, 20% of pure strontium, 10% of cerium-rich mixed rare earth;

[0034] (2) Preheat the pure magnesium at 150-200°C for 20-30 minutes and dry it; then, put the pure magnesium in CO 2 with SF 6 Mixed gas (SF 6 The volume fraction is 0.5%) and put it into a resistance furnace for melting. After melting, when the melt temperature is 700° C., add pure strontium and cerium-rich mixed rare earth to the melt. The method of adding pure strontium is: Pure strontium was taken out from the anti-oxidation environment, dried and wrapped in aluminum foil, and quickly pressed into the melt below the surface of the melt with a bell jar for 5 minutes. Then, stir until the alloying elements are completely dissolved into the melt;

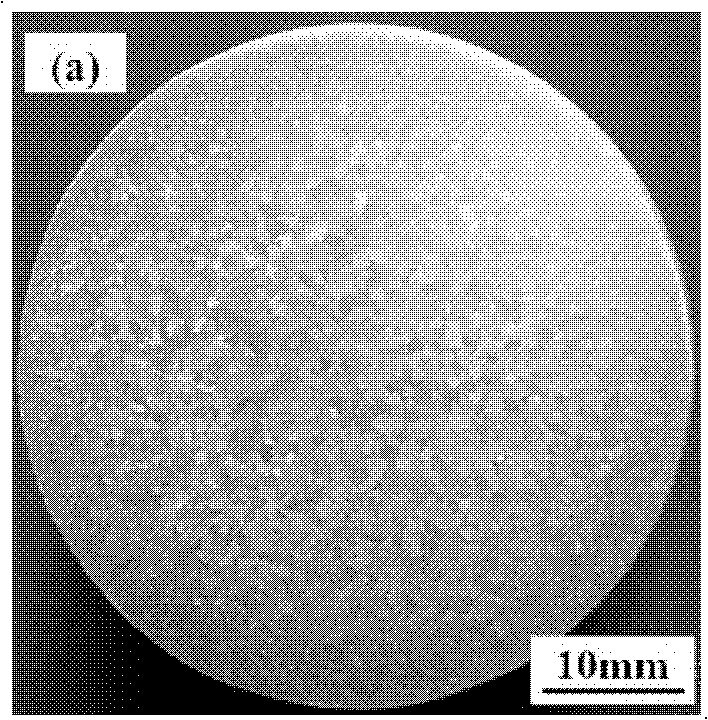

[0035] (3) Heat the melt to 750°C for 30 minutes, then cool it down to 730°C, skim off the scum and cast it into an ingot to obtain a Mg-20Sr-10RE master alloy.

Embodiment 2

[0037] (1) First, the raw materials are weighed by weight percentage: 40% of pure magnesium, 50% of magnesium-strontium master alloy (the weight percentage of strontium is 20%), and 10% of cerium-rich mixed rare earth;

[0038] (2) Preheat the pure magnesium at 150-200°C for 20-30 minutes and dry it; then, put the pure magnesium in CO 2 with SF 6 Mixed gas (SF 6 The volume fraction is 0.5%) and melted in a resistance furnace. After melting, when the melt temperature is 700°C, add magnesium-strontium master alloy and cerium-rich mixed rare earth to the melt, and then stir until the alloy elements are completely dissolved into the melt. melt;

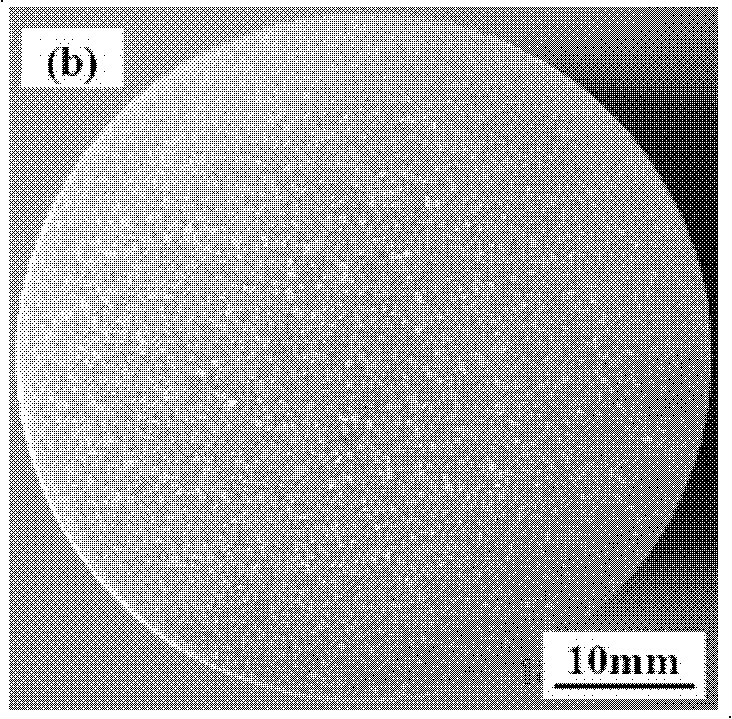

[0039] (3) Heat the melt to 750°C for 30 minutes, then cool it down to 730°C, skim off the scum, cast it into an ingot, and then extrude it into a wire rod to obtain a Mg-10Sr-10RE master alloy.

Embodiment 3

[0041](1) firstly take raw material by weight percentage and be: pure magnesium 20%, magnesium strontium master alloy (the weight percentage of strontium is 20%) 40%, magnesium cerium master alloy (the weight percentage of cerium is 25%) 20%; Magnesium Neodymium master alloy (25% by weight of neodymium) 20%.

[0042] (2) Preheat the pure magnesium at 150-200°C for 20-30 minutes and dry it; then, put the pure magnesium in CO 2 with SF 6 Mixed gas (SF 6 The volume fraction is 0.5%) and melted in a resistance furnace under protection. After melting, when the melt temperature is 700°C, add magnesium-strontium master alloy and magnesium-cerium master alloy to the melt, and then stir until the alloy elements are completely dissolved into the melt. melt;

[0043] (3) Heat the melt to 750°C for 30 minutes, then cool it down to 730°C, skim off the scum, and cast it into an ingot to obtain a Mg-8Sr-5Ce-5Nd master alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com