Patents

Literature

36results about How to "Improve high temperature and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasion-resistant gear for high-speed gear box

ActiveCN106282817AEnhanced heat and corrosion resistanceLight in massMolten spray coatingFoundry mouldsTalcCorrosion

The invention relates to an abrasion-resistant gear for a high-speed gear box. The abrasion-resistant gear comprises C, Cr, Si, Mn, Zn, Cu, Ag, Au, Pt, Ni, W, Mo, Nd, Ce, Eu, Lu, Ti, AlN, S, P, talc powder, magnesium oxide, tungsten carbide, montmorillonite and Fe. The abrasion-resistant gear for the high-speed gear box has the advantages that raw materials for the abrasion-resistant gear contain the Zn, the Ni and the W, and accordingly the heat resistance and the corrosion resistance of the gear can be improved.

Owner:南京创贝高速传动机械有限公司

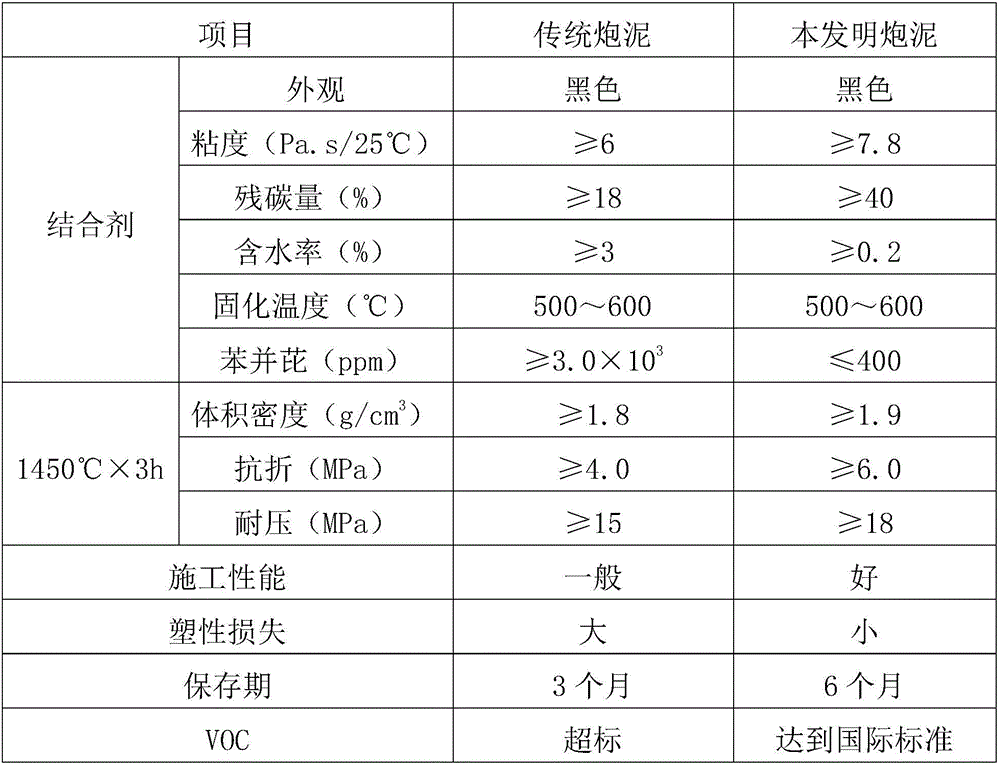

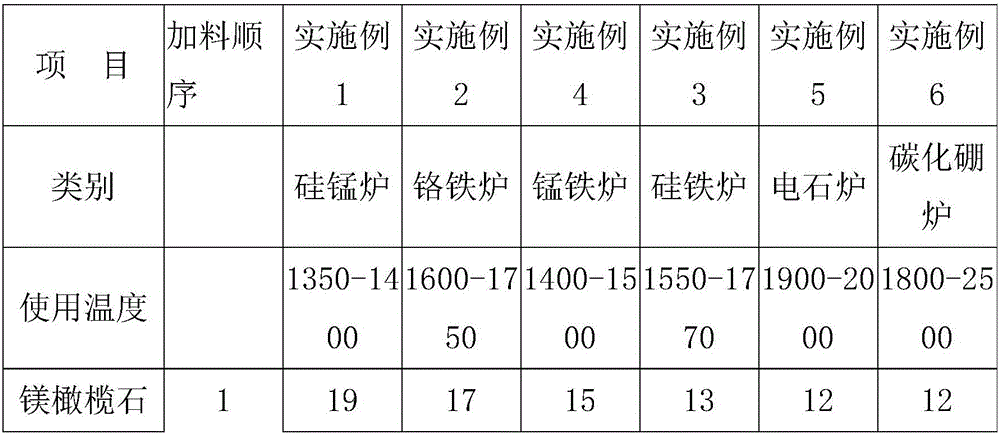

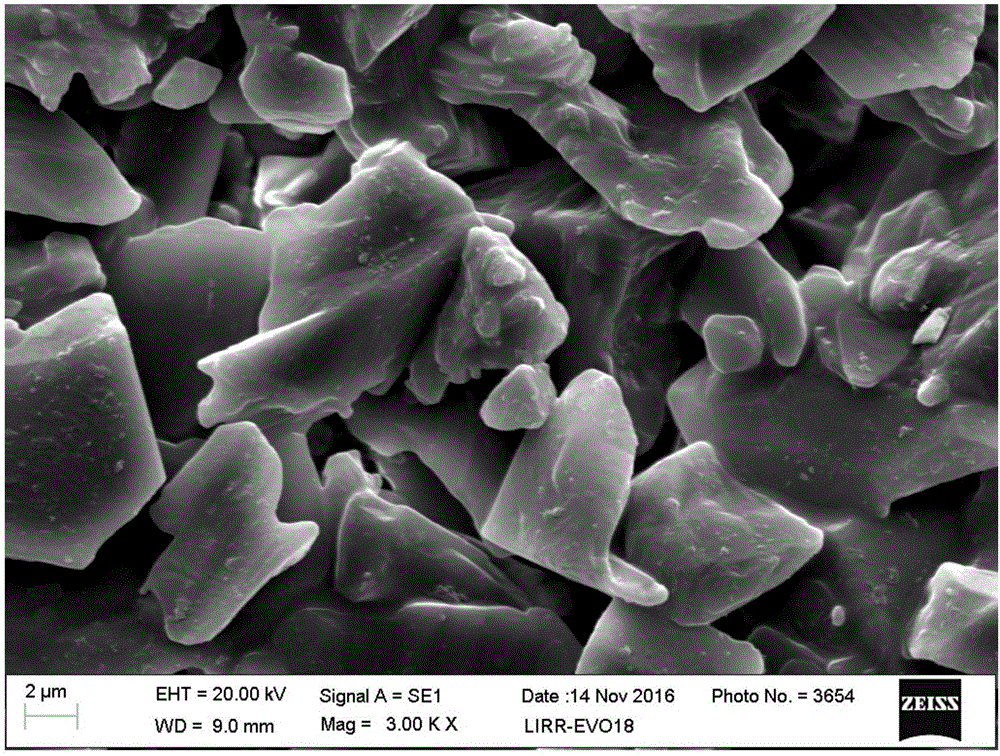

Environment-friendly anhydrous stemming for submerged arc furnace and preparation method

The invention discloses environment-friendly anhydrous stemming for a submerged arc furnace and a preparation method of the environment-friendly anhydrous stemming. The environment-friendly anhydrous stemming is prepared from the following raw materials in parts by weight: 10 to 20 parts of forsterite, 10 to 45 parts of magnesia, 10 to 20 parts of silicon carbide, 10 to 25 parts of coke, 5 to 15 parts of asphalt, 10 to 20 parts of clay, 5 to 15 parts of nitride, 3 to 10 parts of kyanite, 0 to 15 parts of quartz powder, 12 to 20 parts of carbon black oil, 2 to 8 parts of anthracene oil and 0.5 to 2 parts of plasticizer, wherein the nitride is one or a mixture of ferro silicon nitride, silicon nitride, aluminum nitride and titanium nitride, and the carbon black oil and the anthracene oil are premixed to form a composite environment-friendly binding agent for standby use; raw materials are weighed and added into a mixing mill to be dry-mixed; the binding agent is added, mixed and milled; the plasticizer is added and stirred; and the mixture is extruded and molded. The environment-friendly anhydrous stemming is safe to the human body and environment, high in performance, low in consumption, and good in slag erosion resistance and scouring resistance.

Owner:CHINA JINGYE ENG +1

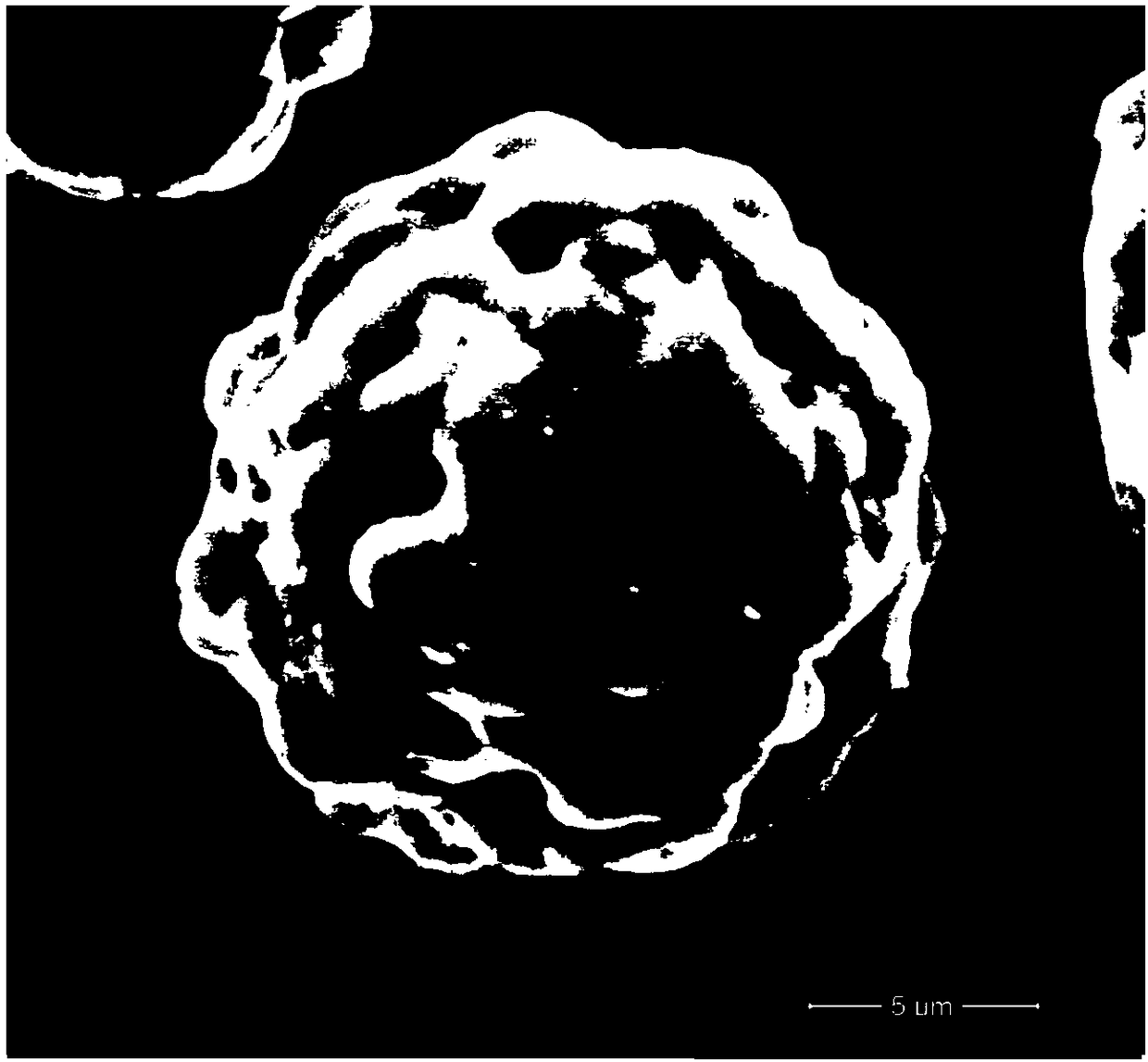

Highly-permeable ultrafiltration composite ceramic coating film and preparation method thereof

ActiveCN107519772AImprove performanceSimple processUltrafiltrationComposite ceramicIn situ polymerization

The invention relates to a highly-permeable ultrafiltration composite ceramic coating film and a preparation method thereof, and belongs to the technical field of film separation. The highly-permeable ultrafiltration composite ceramic coating film comprises a ceramic base film, wherein the surface of the ceramic base film is sequentially provided with a silane coupling layer, a polyimide layer from interior to exterior; the mass ratio of the ceramic base film to the silane coupling layer to the polyimide layer is 1:(0.001 to 0.005):(0.01 to 0.1). The highly-permeable ultrafiltration composite ceramic coating film has the advantages that hyperbranched polyamide-amide is used as a pore passage building template, polyimide is used as a separating film, and the polyimide is grafted to the surface of the ceramic film in a covalent way by in-situ polymerizing, so that the composite separating film can simultaneously reach the high-selectivity and high-permeability advantages of a polymer film and high temperature-resistant and corrosion-resistant advantages of an inorganic film; the pore passage size and structure of the commercial ceramic film are improved, and the good permeability of the separating film is realized.

Owner:佛山市维宁新材料有限公司

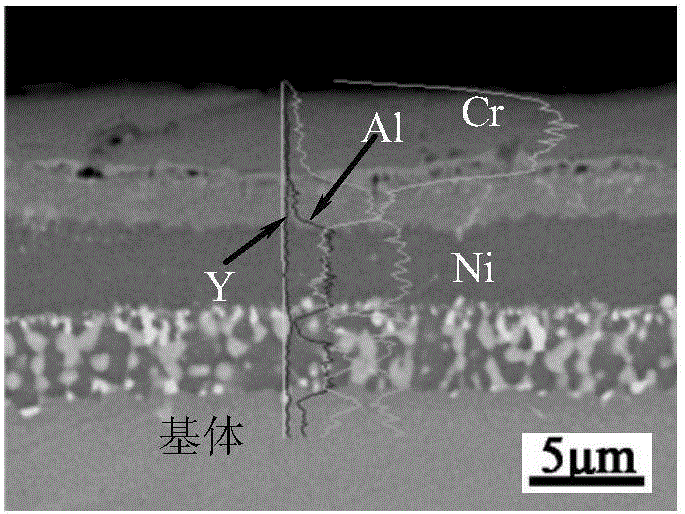

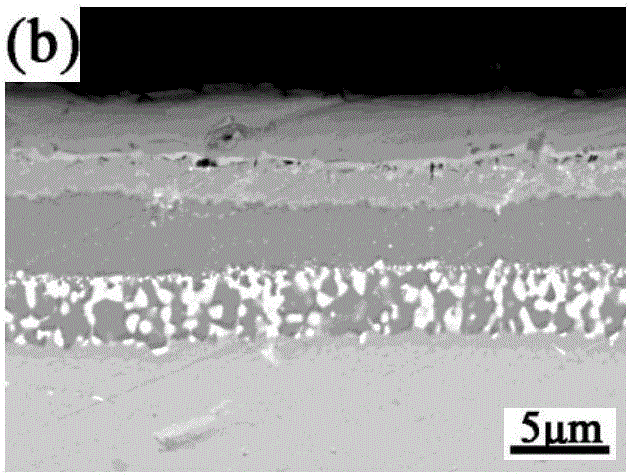

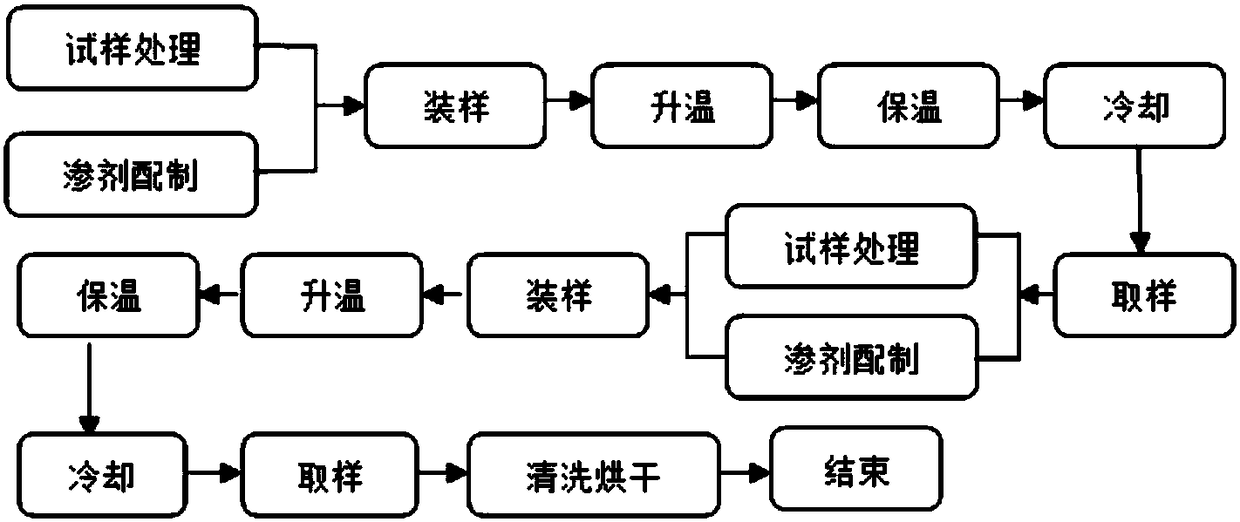

High-temperature alloy oxidation-resistance and corrosion-resistant protective coating

InactiveCN105839048ARealize ternary co-infiltrationImprove high temperature and corrosion resistanceSolid state diffusion coatingRoom temperatureOxidation resistant

The invention discloses a nickel-based high-temperature alloy oxidation-resistance and corrosion-resistant protective coating and a preparation technique thereof. The protective coating is prepared from three elements including Cr, Al and Y through a pack cementation method. The protective coating is prepared from, by weight, 5-10% of Cr, 10-20% of Al, 1-2% of Y2O3, 6-10% of NH4Cl and the balance Al2O3. The preparation technique comprises the steps that raw materials are weighed accurately according to the weight percentage for preparation of the protective coating; then ball milling and drying are conducted; the raw materials are placed into a crucible after being dried; the raw materials are placed in a muffle furnace after being sealed and charged; and the muffle furnace is heated for 40-60 min to the temperature of 1050-1070 DEG C, heat preservation is conducted at the temperature of 1050-1070 DEG C for 2-3 h, then the temperature is decreased to 600 DEG C with the furnace, the raw materials are taken out and cooled to the room temperature, and finally, the protective coating can be obtained through cleaning and drying. According to the protective coating, a Cr-Al-Y coboronising layer is prepared on the surface of the nickel-based alloy, the technical problem that the nickel-based alloy is poor in high-temperature resistance and corrosion resistance is solved, the preparation technique is stable and reliable, the coating is good in binding force, uniform in structure and compact, and the coating thickness is controllable; and the preparation technique has the advantages of being simple, convenient to operate, high in efficiency, low in cost, easy to implement and the like.

Owner:BEIFANG UNIV OF NATITIES

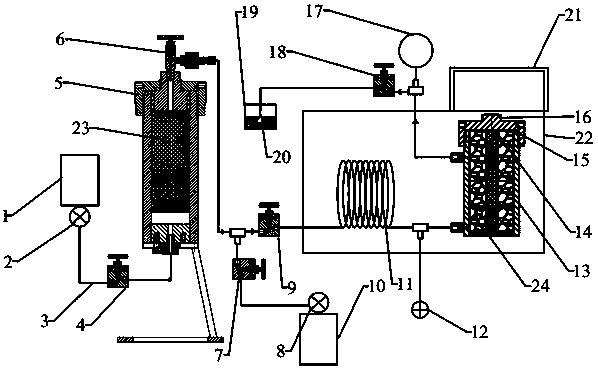

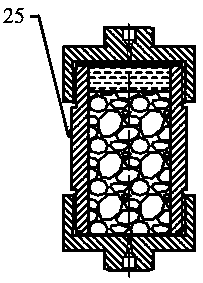

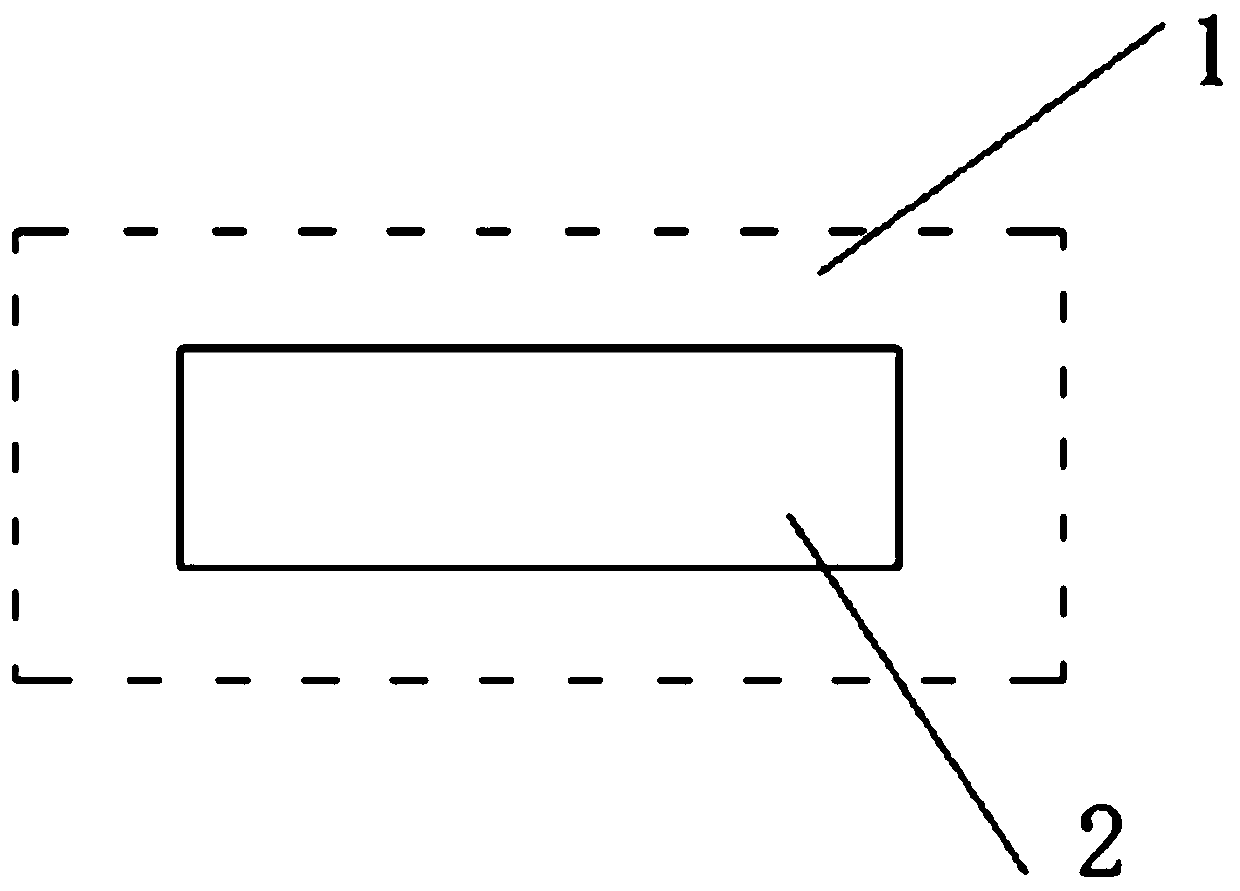

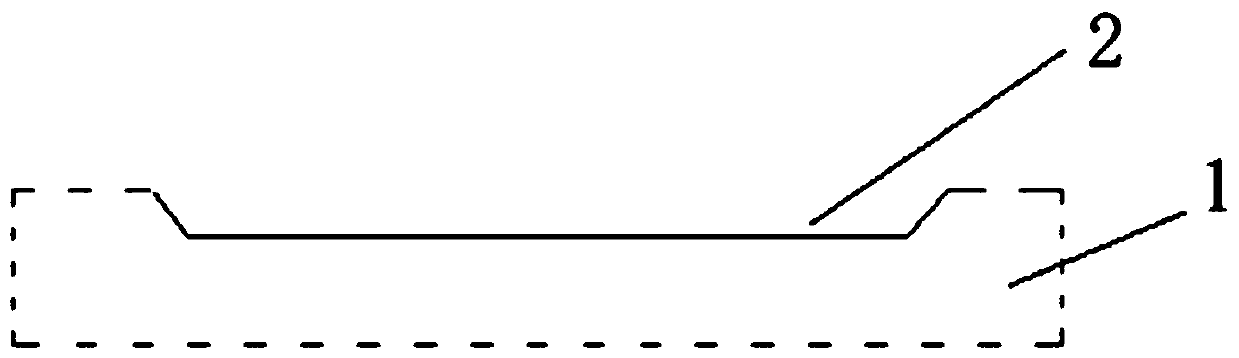

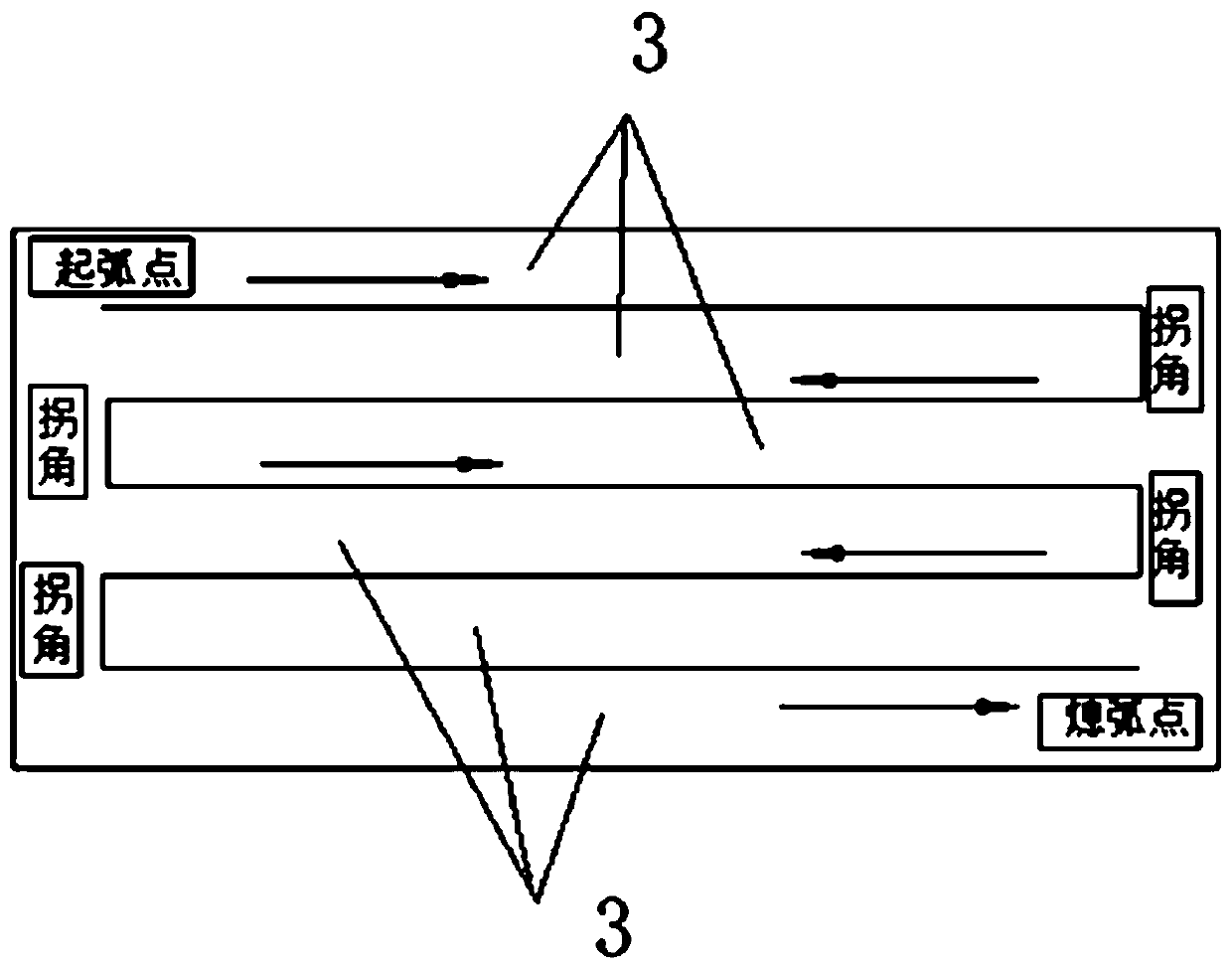

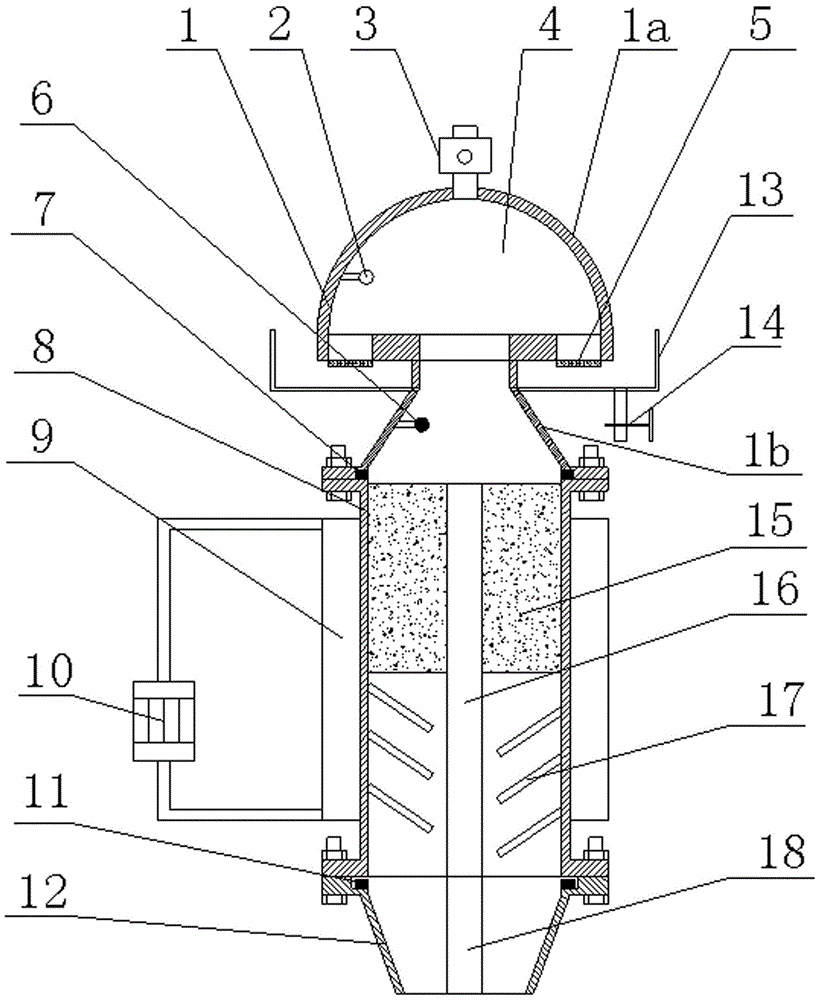

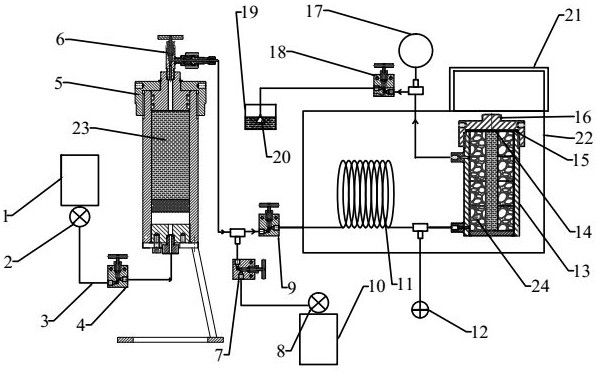

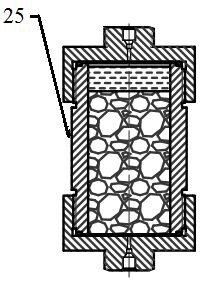

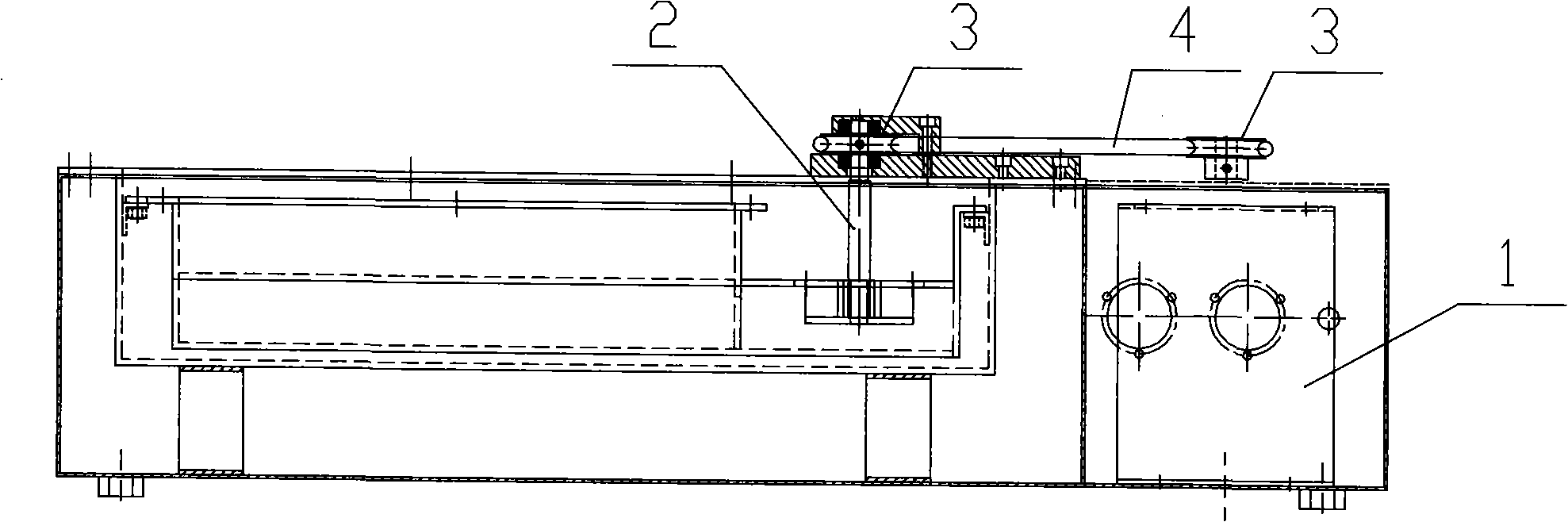

High-temperature water-wet maintenance simulation test device and method of cement stone of thermal production well

ActiveCN109030140AMake up for deficienciesUHT meetsPreparing sample for investigationMaterial strength using tensile/compressive forcesWater wetNitrogen source

The invention discloses a high-temperature water-wet maintenance simulation test device and method of cement stone of a thermal production well. The device is mainly composed of a nitrogen source (1),an intermediate water container (5), a CO2 gas source (10), a flowmetre (12), a closed kettle body A (13), a pressure gage (17), a condenser (19) and a heating furnace (22); cement stone (24) is putin the closed kettle body A (13); the closed kettle body A (13) is in the heating furnace (22); a water inlet is at the lower part of the side part of the kettle body A; the water inlet is separatelyconnected to the flowmetre (12) and a heating pressure manifold (11); the heating pressure manifold (11) is connected to the intermediate water container (5) and the nitrogen source (1), and also connected to the CO2 gas source (10); a water outlet is at the upper part of the side end of the kettle body A; the water outlet is connected to the pressure gage (17) and the condenser (19); the maintenance method can be used for simulating acid medium corrosion of cement stone of the thermal production well at different temperatures; and, if the closed kettle body A (13) is replaced by a closed kettle body B (25), the method can be used for testing the shear cementing strength and the channeling pressure of the cement stone in a high-temperature water-wet environment. The high-temperature water-wet maintenance simulation test device and method in the invention are reliable in principle and simple and convenient to operate, and have wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

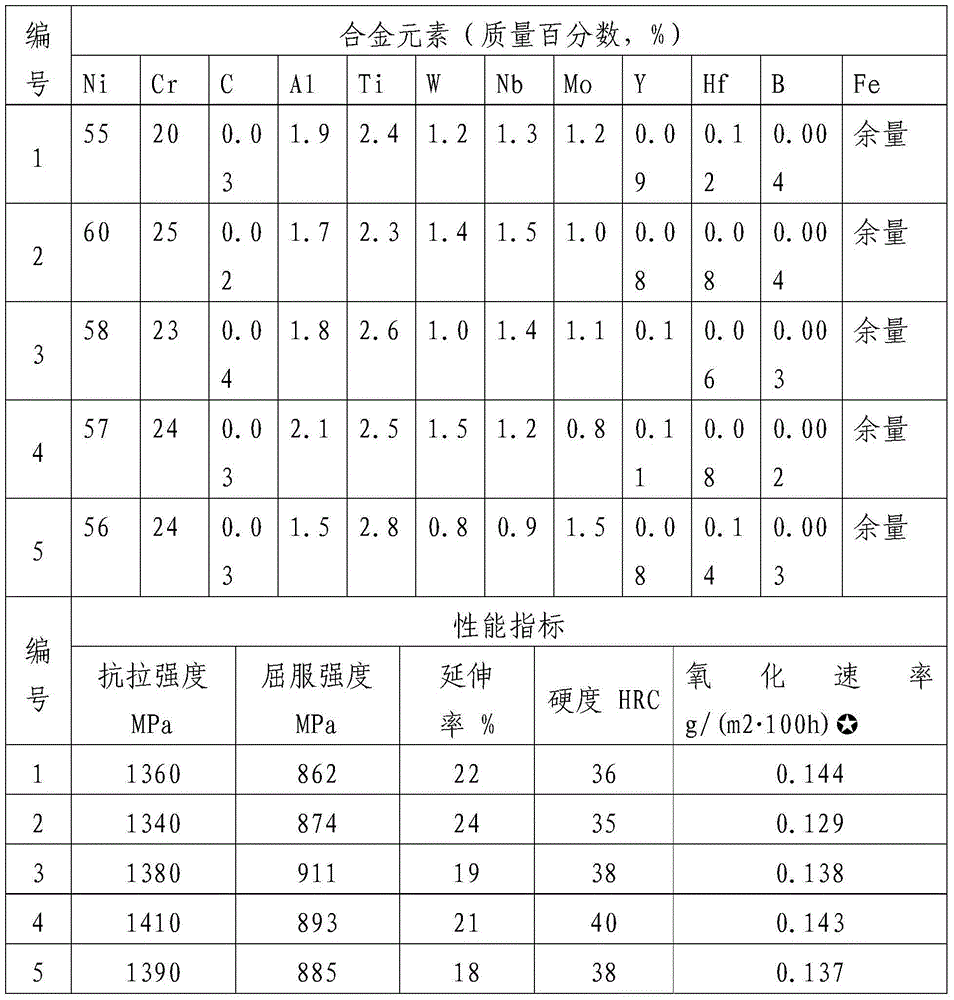

Nickel-based air valve alloy and preparation method thereof

The invention discloses nickel-based air valve alloy. The nickel-based air valve alloy comprises 55.0 to 60.0% of Ni, 20.0 to 25.0% of Cr, 0.01 to 0.05% of C, 1.0 to 3.0% of Al, 1.0 to 3.0% of Ti, 0.5 to 1.5% of W, 0.5 to 1.5% of Nb, 0.5 to 1.5% of Mo, 0.05 to 0.20% of Y, 0.05 to 0.20% of Hf, 0.001 to 0.005% of B, not greater than 0.02% of S, not greater than 0.02% of P, not greater than 0.02% of O, not greater than 0.02% of N, and the balance of Fe and inevitable impurities, wherein the impurity content is not greater than 0.5%. The preparation method comprises the steps of sensing and melting under a vacuum condition; casting an electrode; remelting electroslag; thermally forging; locally modifying and grinding a quadrate ingot blank; thermally rolling; compensating temperature online; thermally rolling a steel wire rod. The nickel-based air valve alloy has high-temperature durability, high-temperature oxidation resistance, high wearability and high-temperature corrosion resistance.

Owner:JIANGSU SHENYUAN SPECIAL STEEL +1

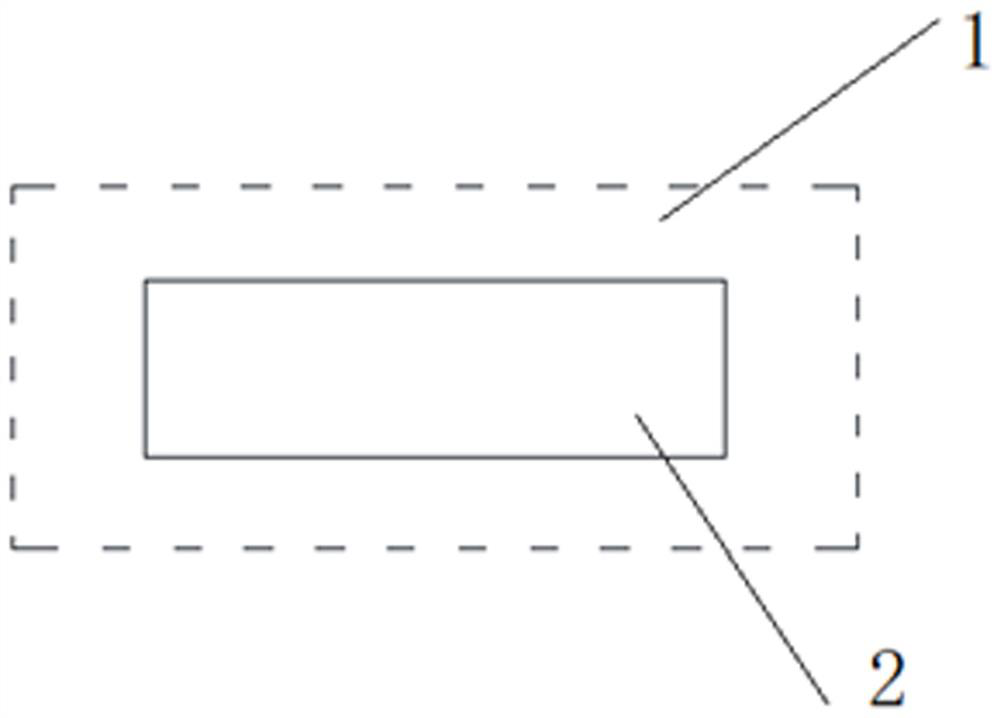

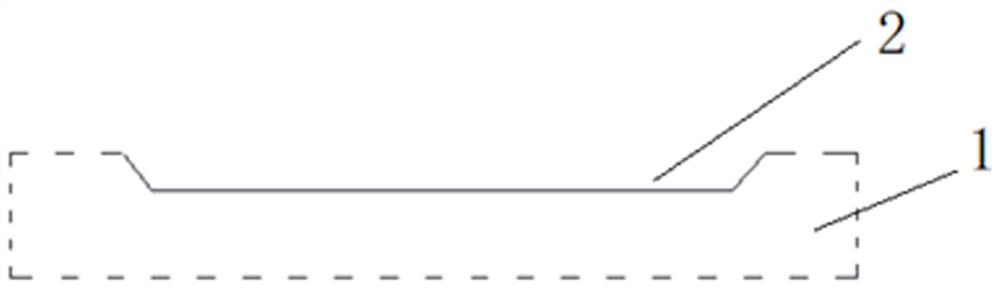

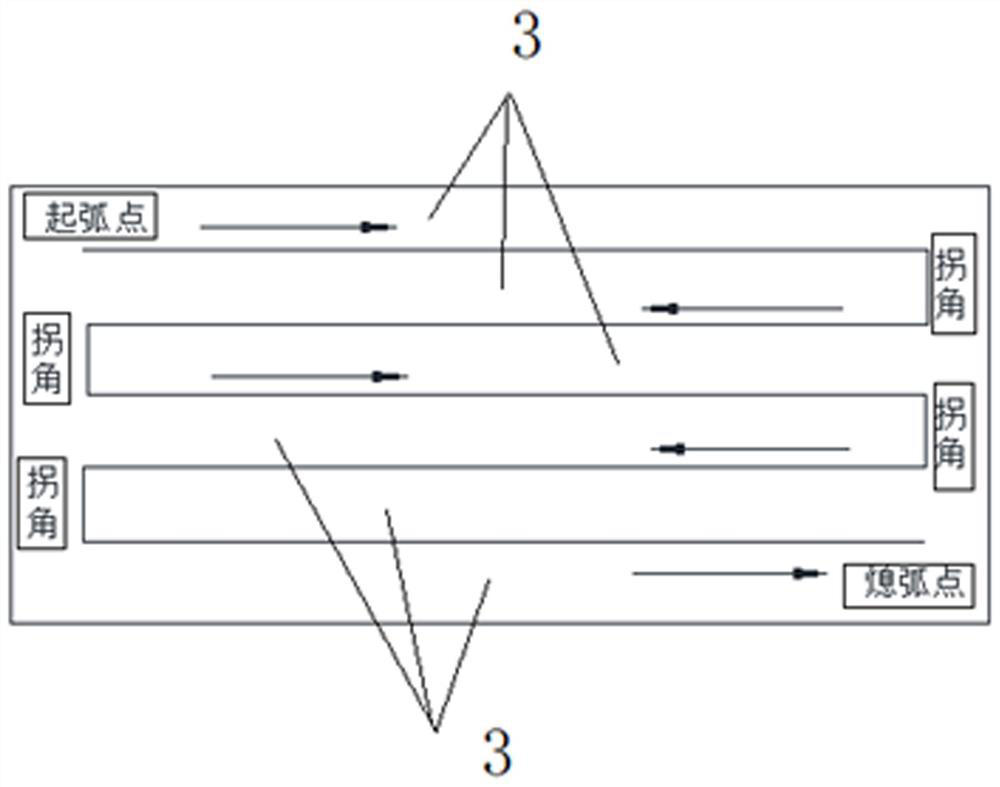

Nickel-based alloy surfacing welding process for alloy tank

ActiveCN110216360ALow dilution rateImprove high temperature and corrosion resistanceArc welding apparatusTemperature resistanceWelding defect

The invention relates to a nickel-based alloy surfacing welding process for an alloy tank. A welding process is carried out by way of cold metal transition welding, and shielded welding is carried outby adopting consumable electrode gas in the welding process. During use, the dilution rate of the surface of the surfacing is reduced greatly, the high-temperature resistance and the corrosion resistance of a material are improved and a welding material is saved by adopting the nickel-based alloy surfacing welding process by way of cold metal transition welding. Meanwhile, a multi-pass surfacingmode with at least two passes is adopted in the welding process to fill the alloy tank, so that the welding defects of incomplete fusion, solder skips and the like during welding can be solved, and the welding quality is guaranteed.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所) +1

Fireproof anti-corrosion coating material and preparation method thereof

ActiveCN109575734AImprove fire and corrosion resistanceStrong heat resistanceFireproof paintsAnti-corrosive paintsPolymer scienceTMPTA

The invention relates to a fireproof anti-corrosion coating material and a preparation method thereof. The fireproof anti-corrosion coating material can effectively solve the problems of poor water resistance, pollution resistance, heat resistance and corrosion resistance of an acrylate polymer emulsion in the prior art by introducing polysilsesquioxane, polysilane, TMPTA and graphene / nano-TiO2 / spiral carbon fiber composite particles to modify the acrylate polymer skeleton, so that the prepared aqueous acrylate polymer emulsion has better water resistance, pollution resistance, heat resistanceand corrosion resistance and strong fireproof and anti-corrosion performance.

Owner:深圳市天翔科技有限公司

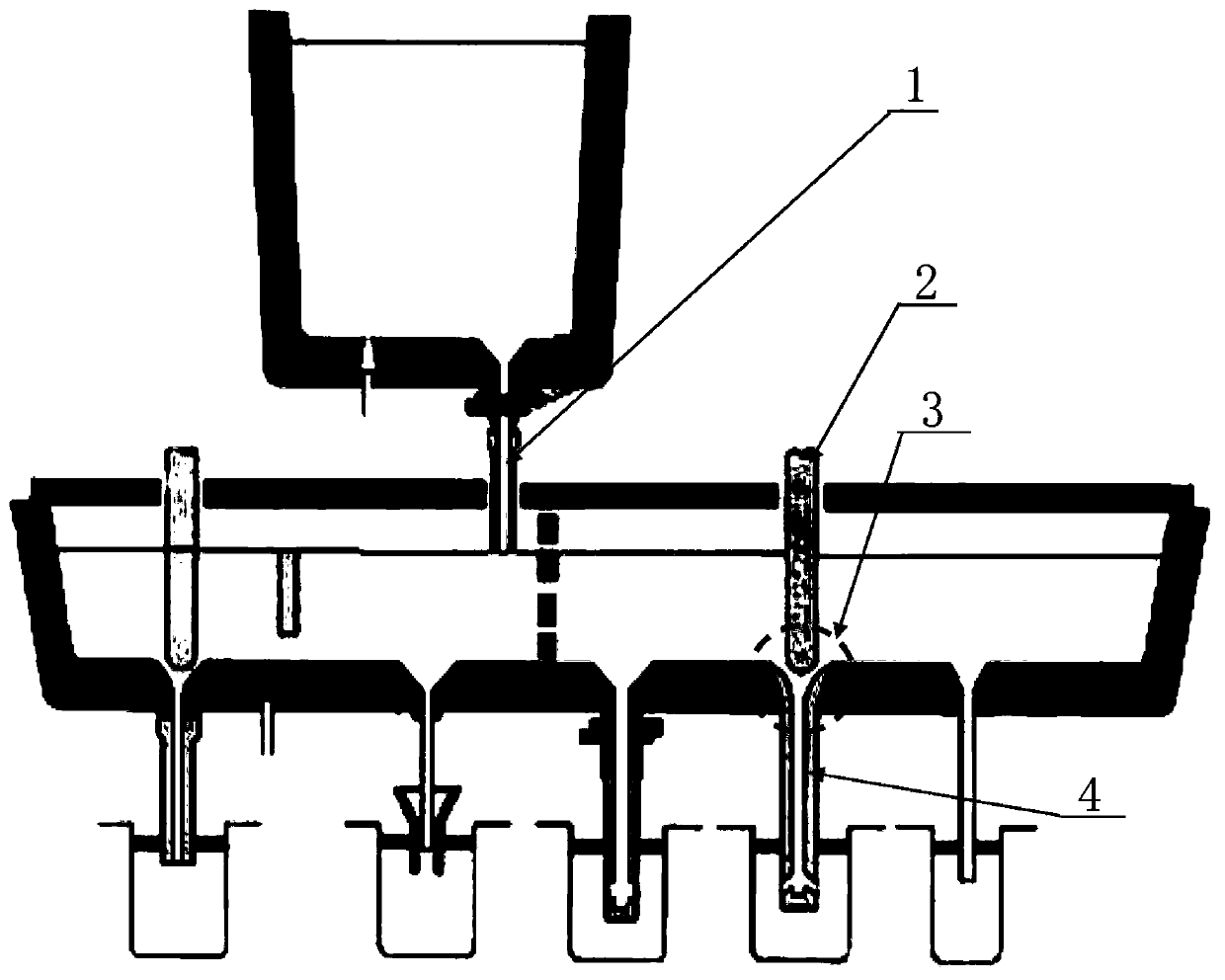

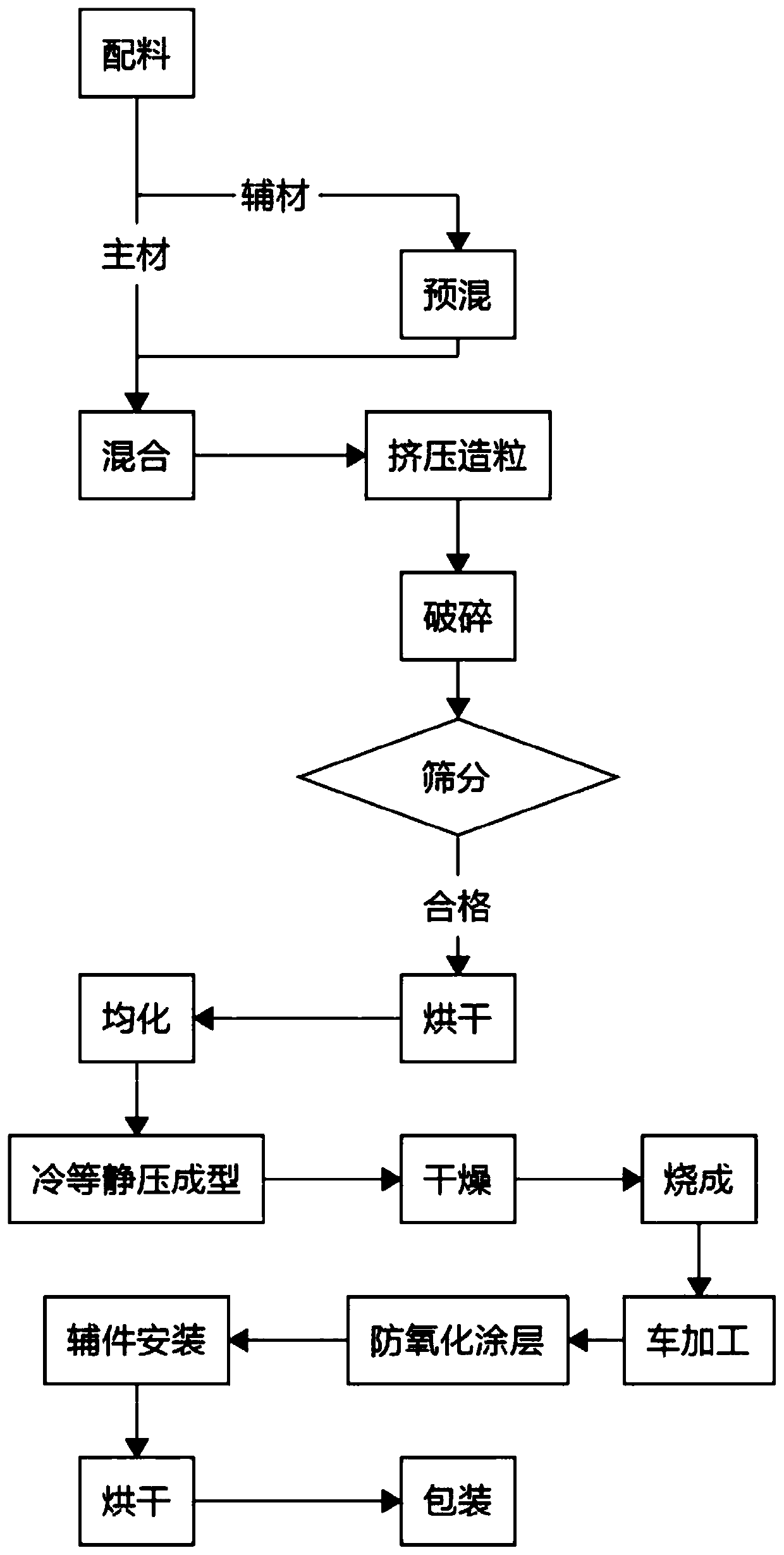

Long-life anticorrosive submersed nozzle for smelting stainless steel, and production method thereof

The invention discloses a long-life anticorrosive submersed nozzle and a production method thereof. The slag line position material of the long-life anticorrosive submersed nozzle comprises, by weight, 20-30 parts of calcium oxide stabilized zirconia or baddeleyite with a size of 40 meshes, 20-30 parts of calcium oxide stabilized zirconia or baddeleyite with a size of 100 meshes, 25-35 parts of calcium oxide stabilized zirconia or baddeleyite with a size of 325 meshes, 5-15 parts of flake graphite, 0-5 parts of SiC powder, 0.5-5 parts of metal Si powder, 0-3 parts of B4C powder, 2-6 parts of calcium hexaluminate with a size of 180 meshes, 4-8 parts of liquid resin and 0-2 parts of solid resin powder. The high-temperature anticorrosion property of the slag line position refractory materialof the submersed nozzle is improved by optimizing the process ratio of the slag line position refractory material of the submersed nozzle and introducing an extruding granulation technology; and the infiltration and erosion induced deterioration melting loss and shedding of the slag line position of the submersed nozzle are delayed to prolong the service life of the submersed nozzle.

Owner:鞍山市和丰耐火材料有限公司

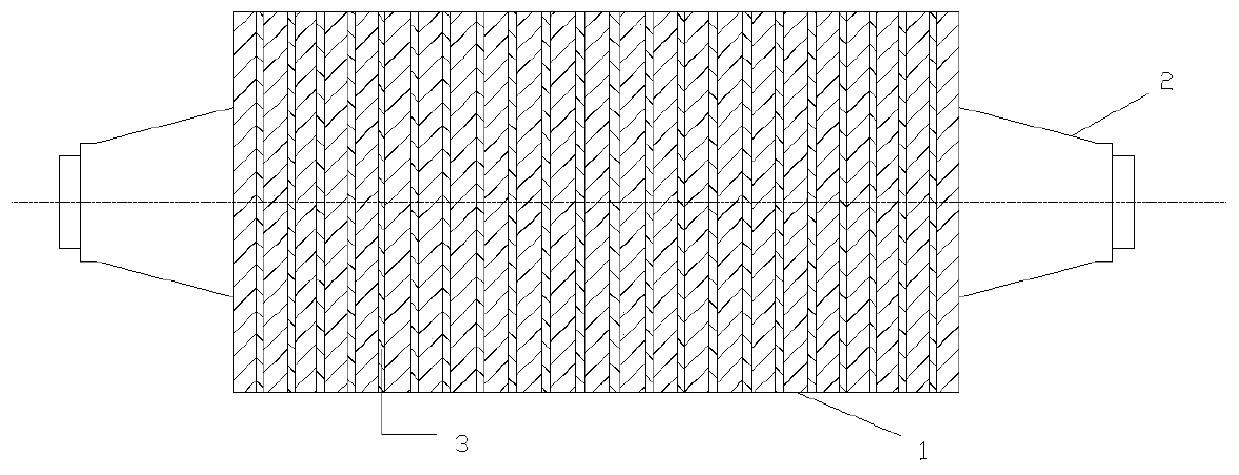

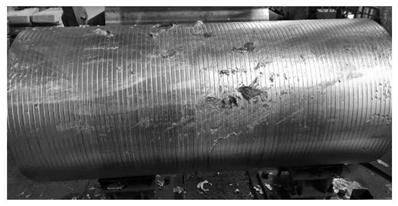

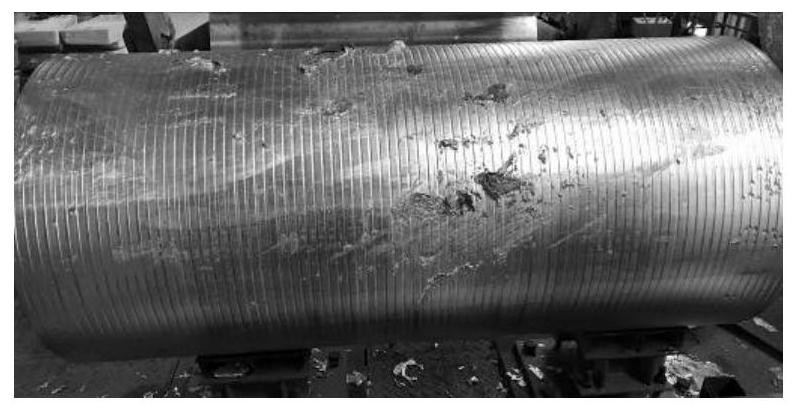

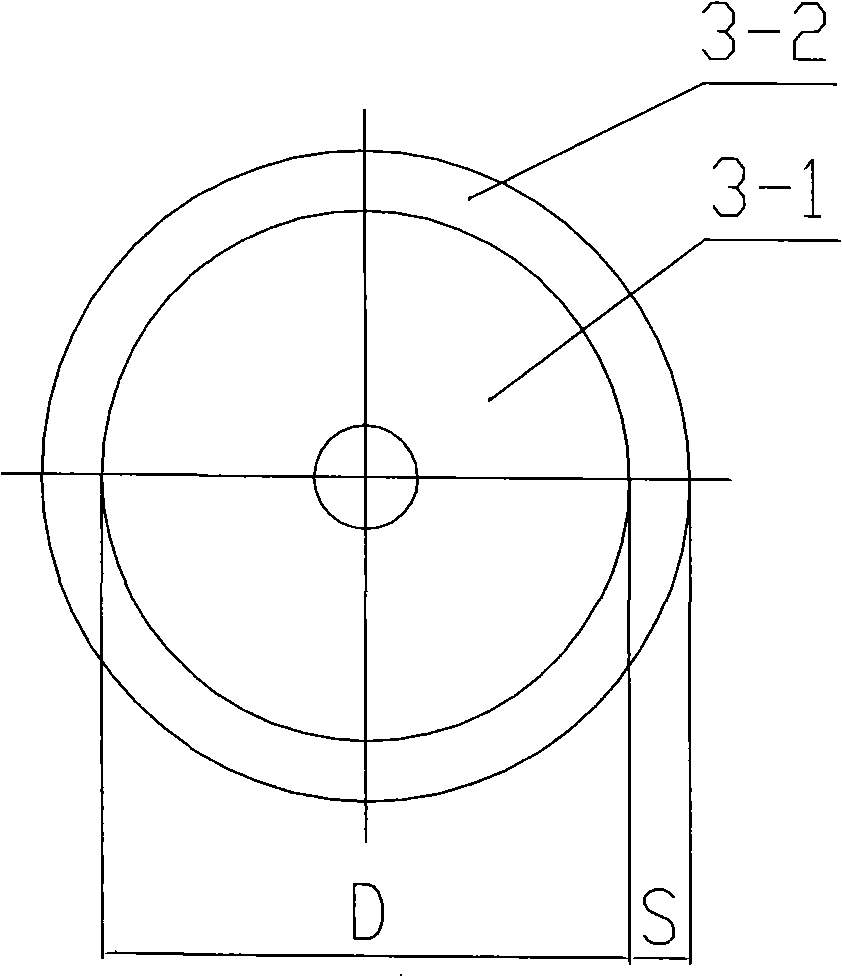

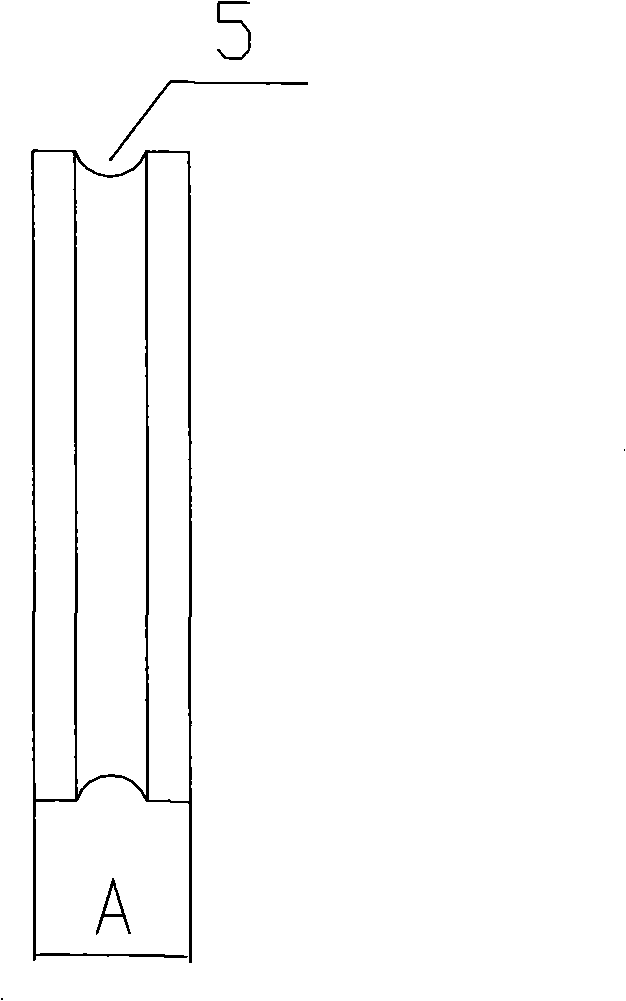

High-temperature-resistant and corrosion-resistant sinking roller and manufacturing method thereof

ActiveCN110306143AReduce corrosion rateExtended service lifeHot-dipping/immersion processesMolten spray coatingMaterials preparationStellite alloy

The invention discloses a high-temperature-resistant and corrosion-resistant sinking roller and a manufacturing method thereof, and belongs to the field of hot dipping equipment. The high-temperature-resistant and corrosion-resistant sinking roller comprises a roller body and a roller shaft, the surfaces of the roller body and the roller shaft are sprayed with coatings, and coating materials are prepared from following raw materials including, by weight, 70-90 parts of WC, 8-15 parts of Co and 3-15 parts of Cr3C2; the surface of the roller body is circumferentially provided with a groove, thebottom surface of the groove is a circular arc transition curved surface; the roller body is made of 316L stainless steel; and the roller shaft is made of a tungsten chromium cobalt alloy. The sinkingroller is made through groove processing, pre-treatment, coating material preparation and supersonic flame spraying. According to the high-temperature-resistant and corrosion-resistant sinking rollerand the manufacturing method, the surfaces of the roller body and the roller shaft of the sinking roller are sprayed with the coating materials with the specific components, the corrosion rate of thesinking roller is greatly reduced, and the service life of the sinking roller is effectively prolonged.

Owner:MAANSHAN IRON & STEEL CO LTD

A high-temperature alloy anti-oxidation and corrosion-resistant protective coating and penetrating agent

InactiveCN105839048BImprove high temperature and corrosion resistanceImprove efficiencySolid state diffusion coatingRoom temperatureOxidation resistant

The invention discloses a nickel-based high-temperature alloy oxidation-resistance and corrosion-resistant protective coating and a preparation technique thereof. The protective coating is prepared from three elements including Cr, Al and Y through a pack cementation method. The protective coating is prepared from, by weight, 5-10% of Cr, 10-20% of Al, 1-2% of Y2O3, 6-10% of NH4Cl and the balance Al2O3. The preparation technique comprises the steps that raw materials are weighed accurately according to the weight percentage for preparation of the protective coating; then ball milling and drying are conducted; the raw materials are placed into a crucible after being dried; the raw materials are placed in a muffle furnace after being sealed and charged; and the muffle furnace is heated for 40-60 min to the temperature of 1050-1070 DEG C, heat preservation is conducted at the temperature of 1050-1070 DEG C for 2-3 h, then the temperature is decreased to 600 DEG C with the furnace, the raw materials are taken out and cooled to the room temperature, and finally, the protective coating can be obtained through cleaning and drying. According to the protective coating, a Cr-Al-Y coboronising layer is prepared on the surface of the nickel-based alloy, the technical problem that the nickel-based alloy is poor in high-temperature resistance and corrosion resistance is solved, the preparation technique is stable and reliable, the coating is good in binding force, uniform in structure and compact, and the coating thickness is controllable; and the preparation technique has the advantages of being simple, convenient to operate, high in efficiency, low in cost, easy to implement and the like.

Owner:BEIFANG UNIV OF NATITIES

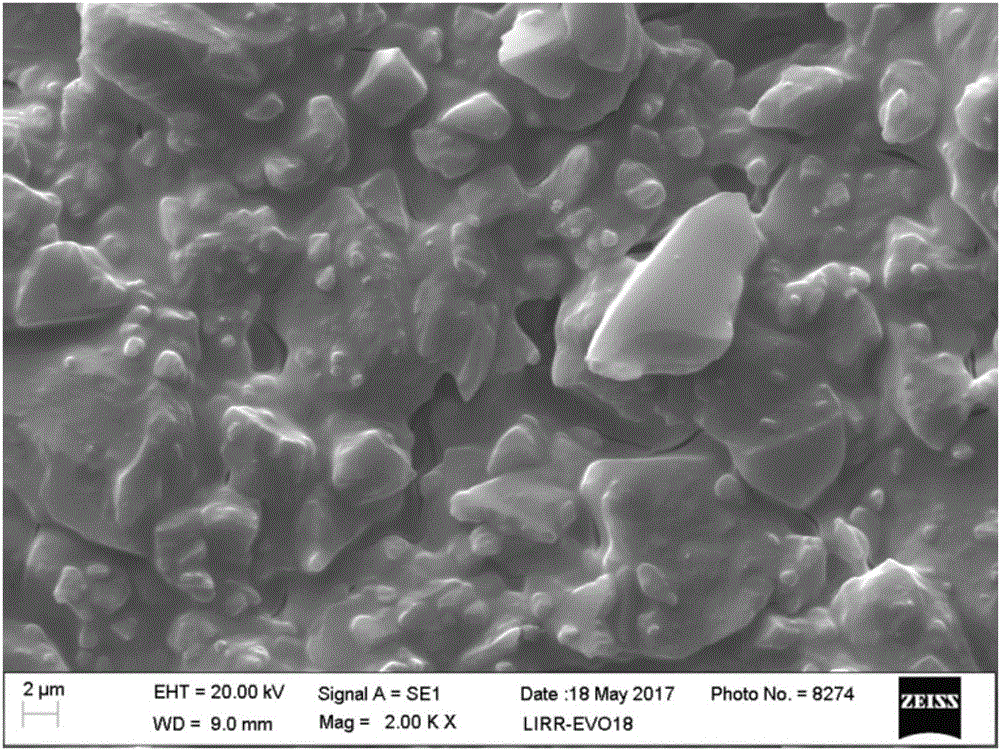

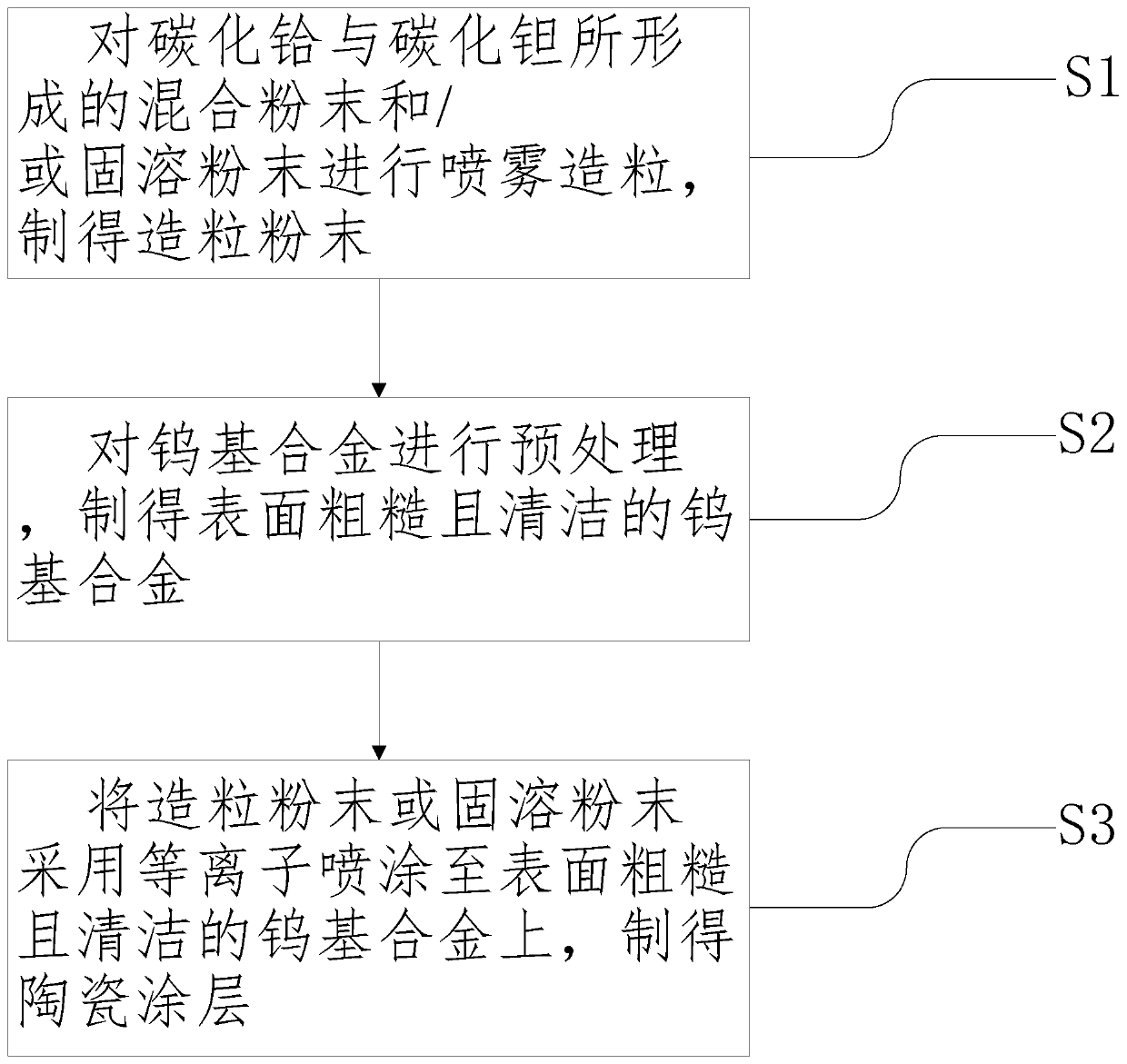

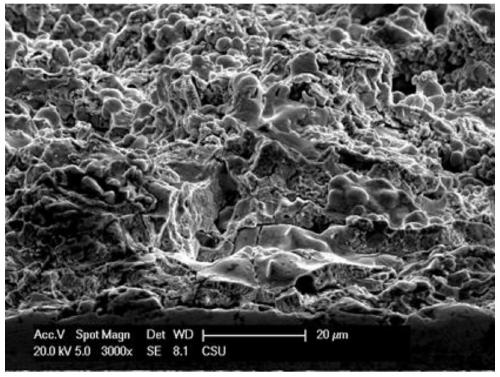

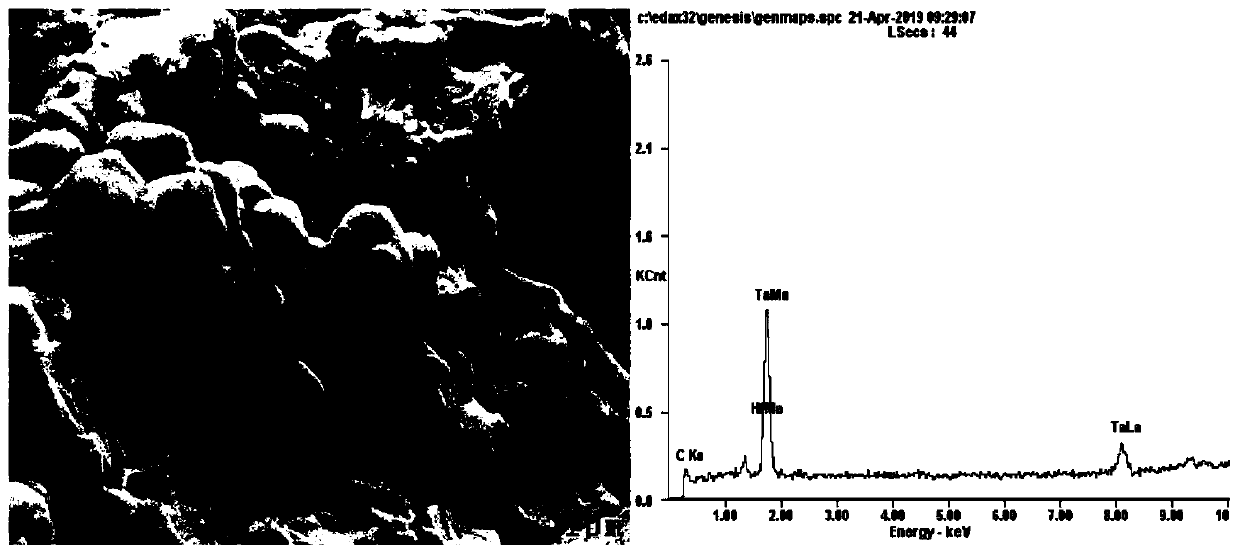

Method for preparing ceramic coating on surface of tungsten-based alloy substrate, ceramic coating and tungsten-based alloy with coating

InactiveCN110042338AImprove performanceImprove high temperature and corrosion resistanceMolten spray coatingSpray GranulationRough surface

The invention discloses a method for preparing a ceramic coating on the surface of a tungsten-based alloy substrate, a ceramic coating and a tungsten-based alloy with the coating. The method comprisesthe following steps of carrying out spray granulation on mixed powder and / or solid solution powder formed by hafnium carbide and tantalum carbide to prepare granulation powder; pre-treating the tungsten-based alloy to prepare the tungsten-based alloy with rough surface and cleanness; and carrying out plasma spraying on the granulation powder to the surface rough and clean tungsten-based alloy toprepare the ceramic coating. Preferably, the mixed powder is subjected to spray granulation by using the solid solution powder formed by the hafnium carbide and the tantalum carbide. According to themethod, the tantalum carbide-hafnium carbide composite ceramic coating is prepared on the tungsten-based alloy through plasma spraying, and the method has the advantages of being high in efficiency, high in pertinency, simple to operate, good in coating quality and the like. The damage to the tungsten-based alloy in the coating process is small, the smooth spraying of the coating is ensured, and the excellent performance of the tungsten-based alloy is kept.

Owner:XIANGTAN UNIV

Environment-friendly vent cap for high-speed gearbox

ActiveCN106286786AEffective interceptionReduce pollutionMolten spray coatingGear lubrication/coolingProduct gasCopper

The invention relates to an environment-friendly vent cap for a high-speed gearbox. The environment-friendly vent cap comprises a vent hood, a vent pipe and a base, the vent hood and the upper end of the vent pipe are fixedly connected, and the base and the lower end of the vent pipe are fixedly connected; a cavity is formed in a hood body at the upper end of the vent hood, a vent hood connection portion is formed at the lower end of the vent hood, the vent hood is provided with an exhaust port, and a foam copper filter screen is arranged at the exhaust port; a gas and oil separator is arranged at the upper end in the vent pipe, oil baffle plates are arranged at the lower end in the vent pipe, and a first oil return pipeline is arranged in the vent pipe; a second oil return pipeline is arranged in the base and communicated with the first oil return pipeline, and the vent pipe is wrapped by a clamp jacket communicated with a circulating water pump. According to the environment-friendly vent cap for the high-speed gearbox, by means of multiple cooperation of the foam copper filter screen, the gas and oil separator and the oil baffle plates, oil gas in high-temperature gas exhausted from the high-speed gearbox can be effectively intercepted, the oil gas in exhausted gas is greatly reduced, environment pollution is reduced, and the environmental protection effect is significant.

Owner:南京创贝高速传动机械有限公司

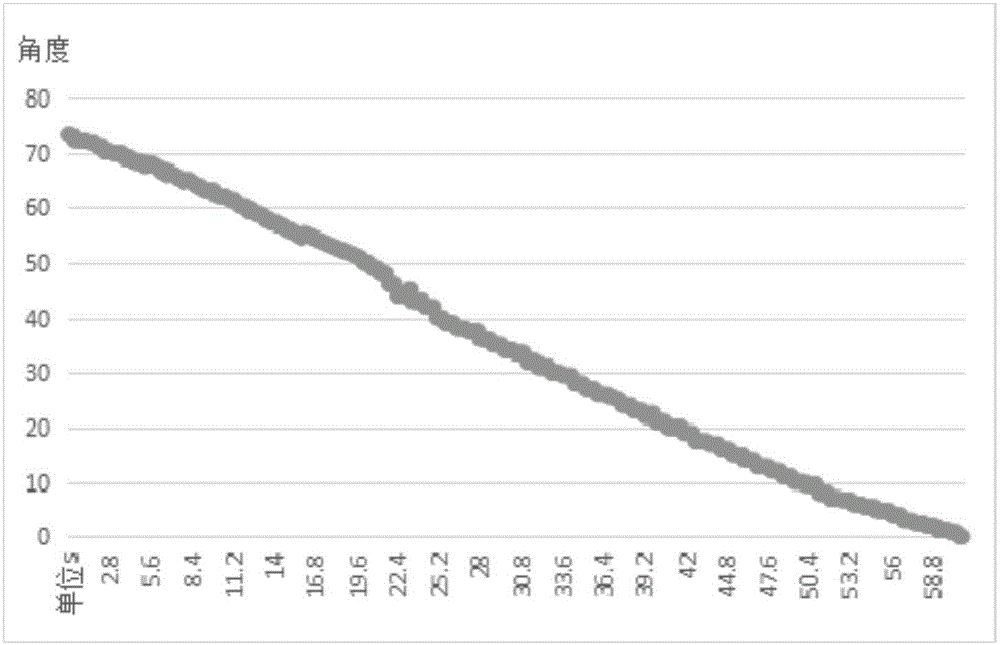

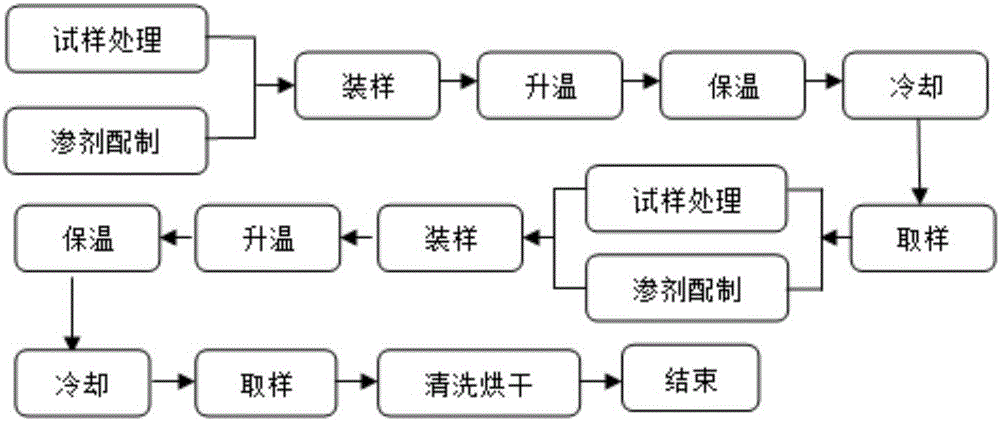

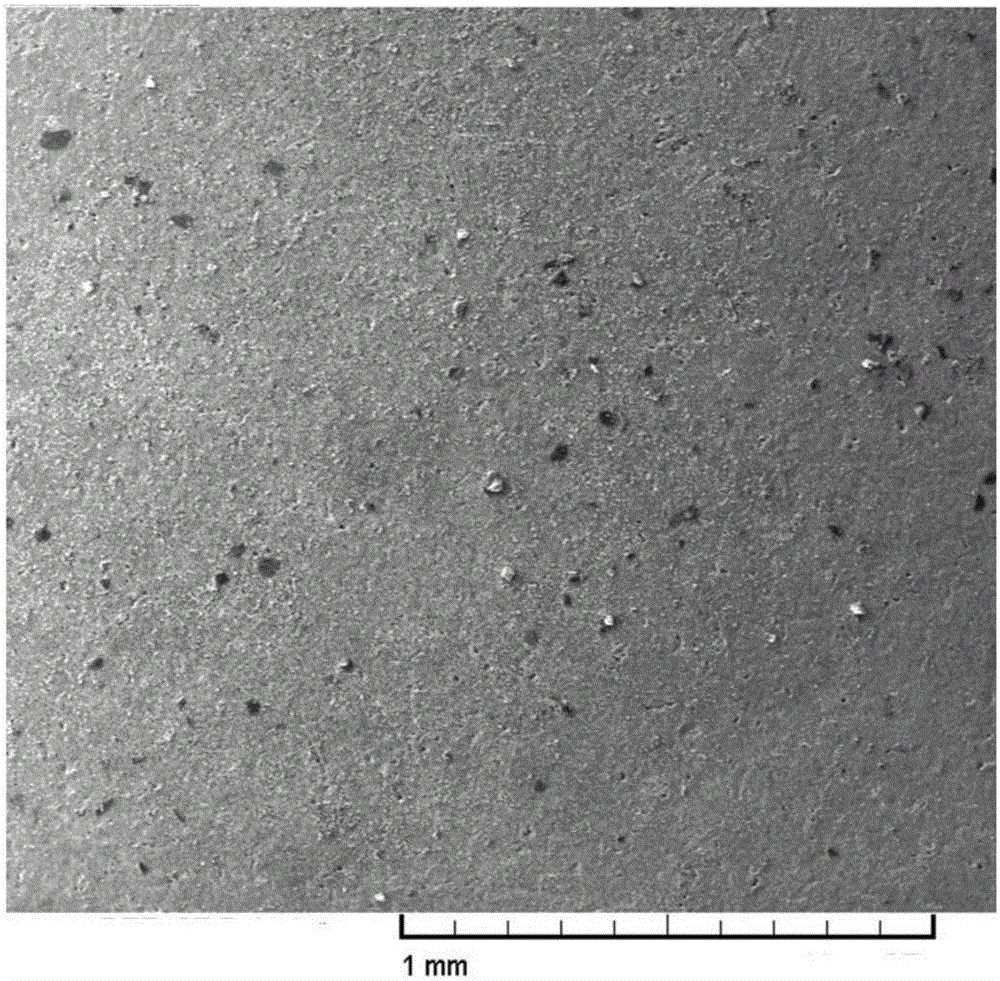

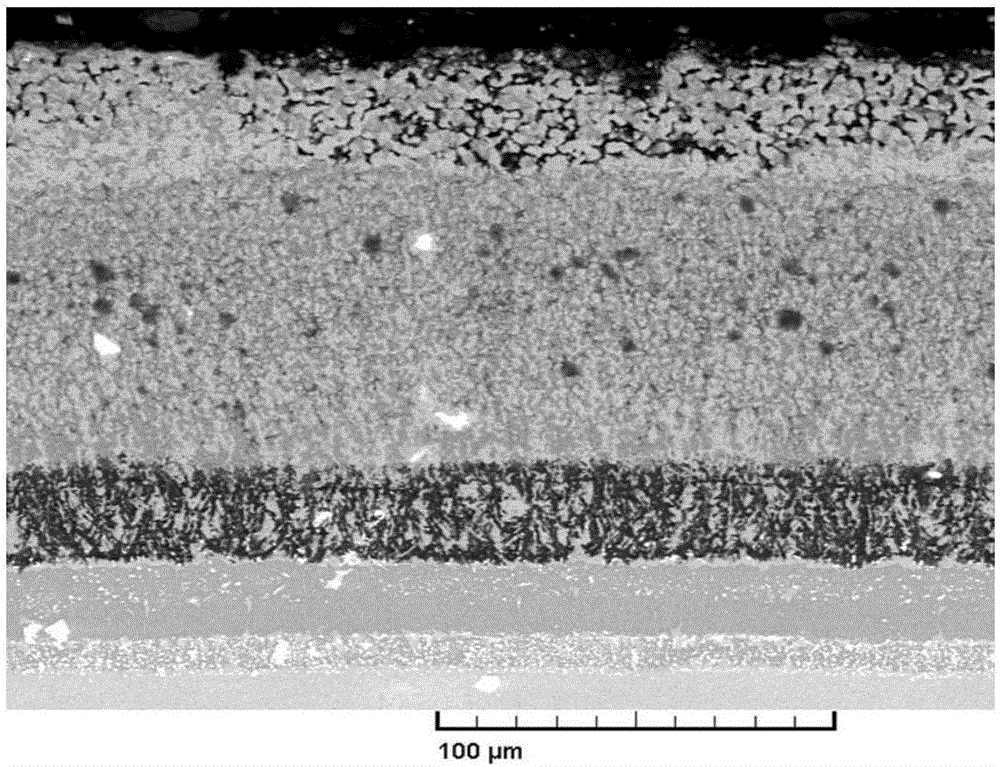

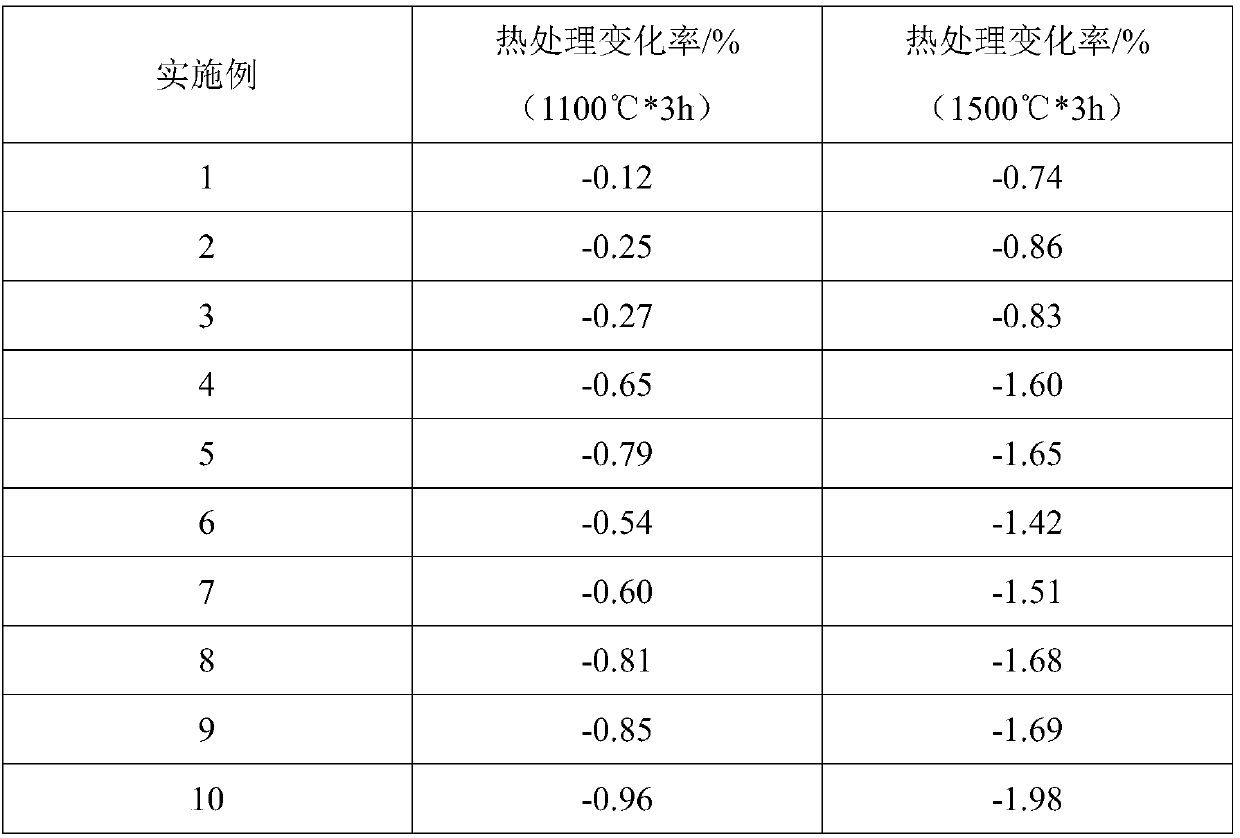

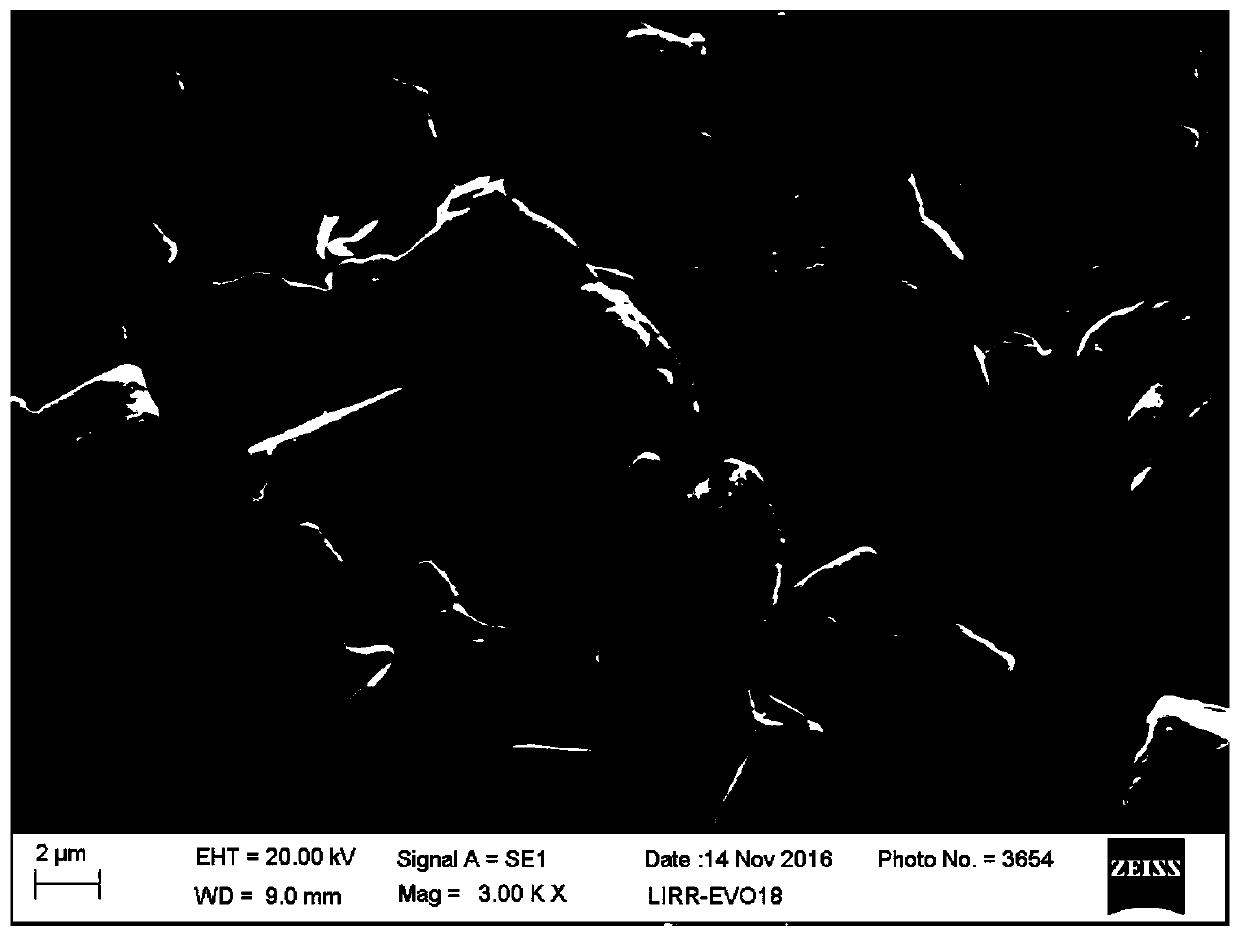

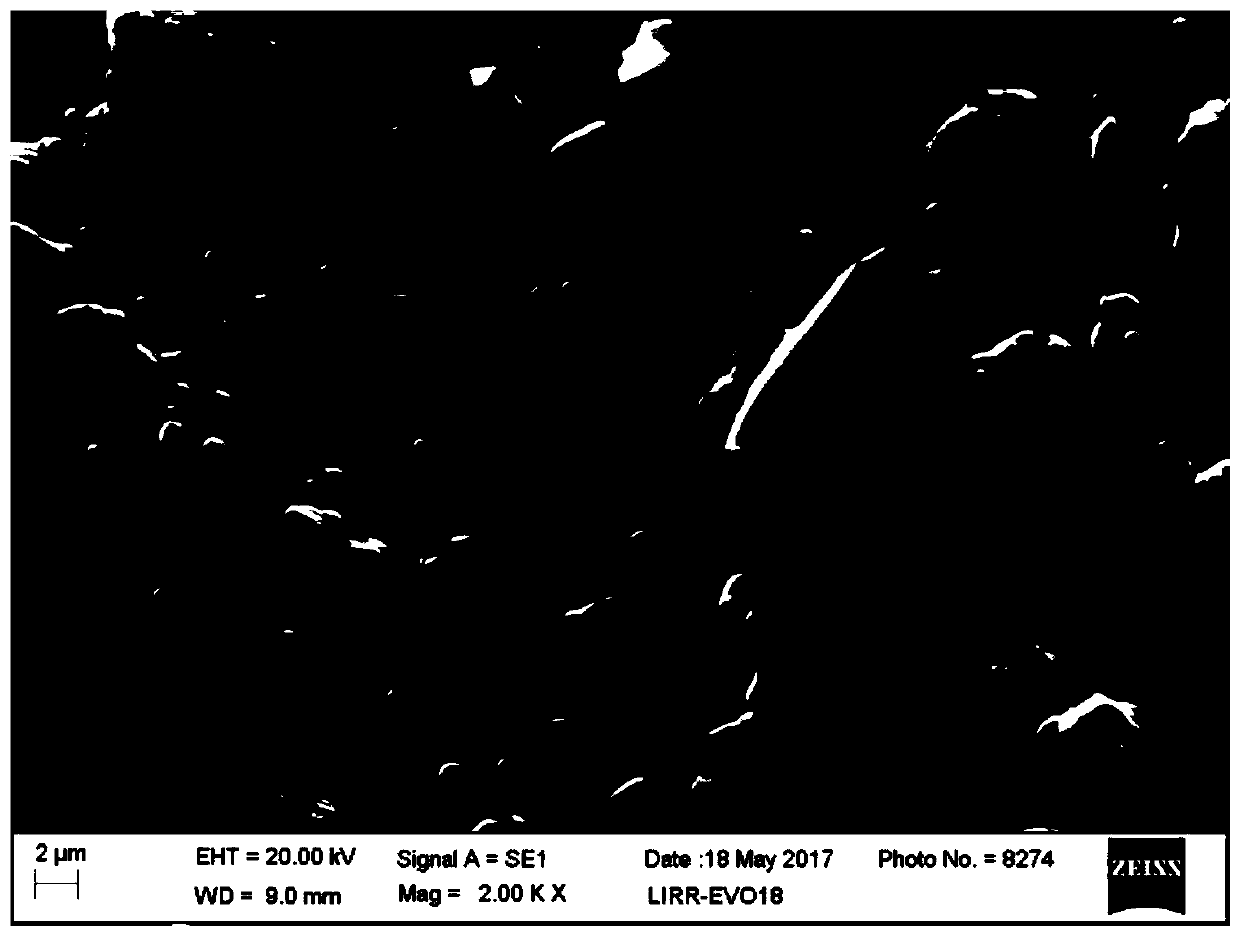

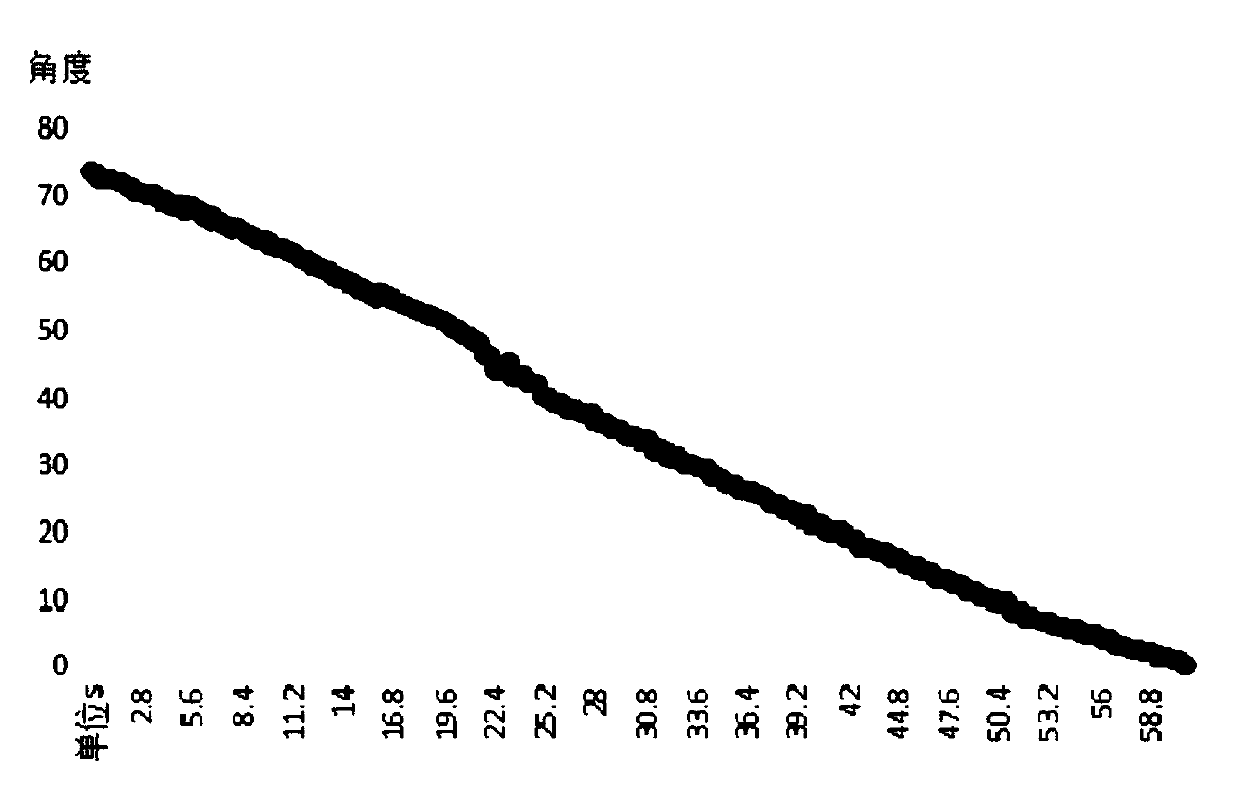

Impregnation agent for surface modification of nickel base alloy and utilization method of impregnation agent

ActiveCN106521405AImprove high temperature and corrosion resistanceImprove bindingSolid state diffusion coatingAlloySurface modification

The invention relates to an impregnating layer for high temperature resistance and corrosion resistance surface modification of a nickel base alloy, and application of the impregnating layer. An impregnation agent comprises an Al-Y impregnation agent and a Cr-Y impregnation agent, wherein the Al-Y impregnation agent comprises the following components by weight percent: 10% to 15% of Al, 1% to 2% of Y2O3 and 6% to 10% of NH4Cl, and the balance being Al2O3; and the Cr-Y impregnation agent comprises the following components by weight percent: 12% to 18% of Cr, 1% to 2% of Y2O3 and 6% to 10% of NH4Cl, and the balance being Al2O3. A Cr-Al-Y composite impregnating layer can be prepared on the surface of the nickel base alloy through a two-step method by virtue of the impregnation agent, and the corrosion property of the obtained alloy is improved by 3 to 5 times compared with the corrosion property of a matrix alloy.

Owner:BEIFANG UNIV OF NATITIES

Dry material for fire resistance

InactiveCN111116213AHigh strengthImprove high temperature and corrosion resistancePhysical chemistryEngineering

The invention provides a dry material for fire resistance. The dry material comprises the following components in parts by weight: 60-95 parts of magnesite, 5-33 parts of forsterite sand, 3-5 parts ofa high-temperature binding agent A, 0.2-2 parts of a high-temperature binding agent B and 0.5-1.5 parts of an auxiliary agent. The dry material for fire resistance provided by the invention can significantly enhance strength and is capable of enhancing high-temperature resistance, corrosion resistance, density, anti-seismic property and thermal stability.

Owner:张家港市恒乐阳方高温材料有限公司

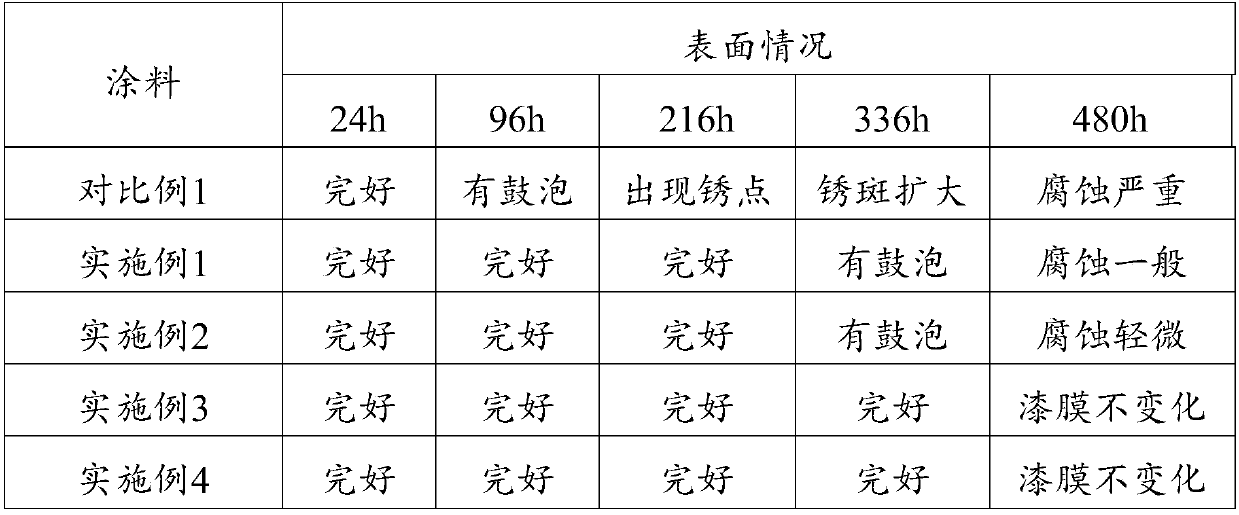

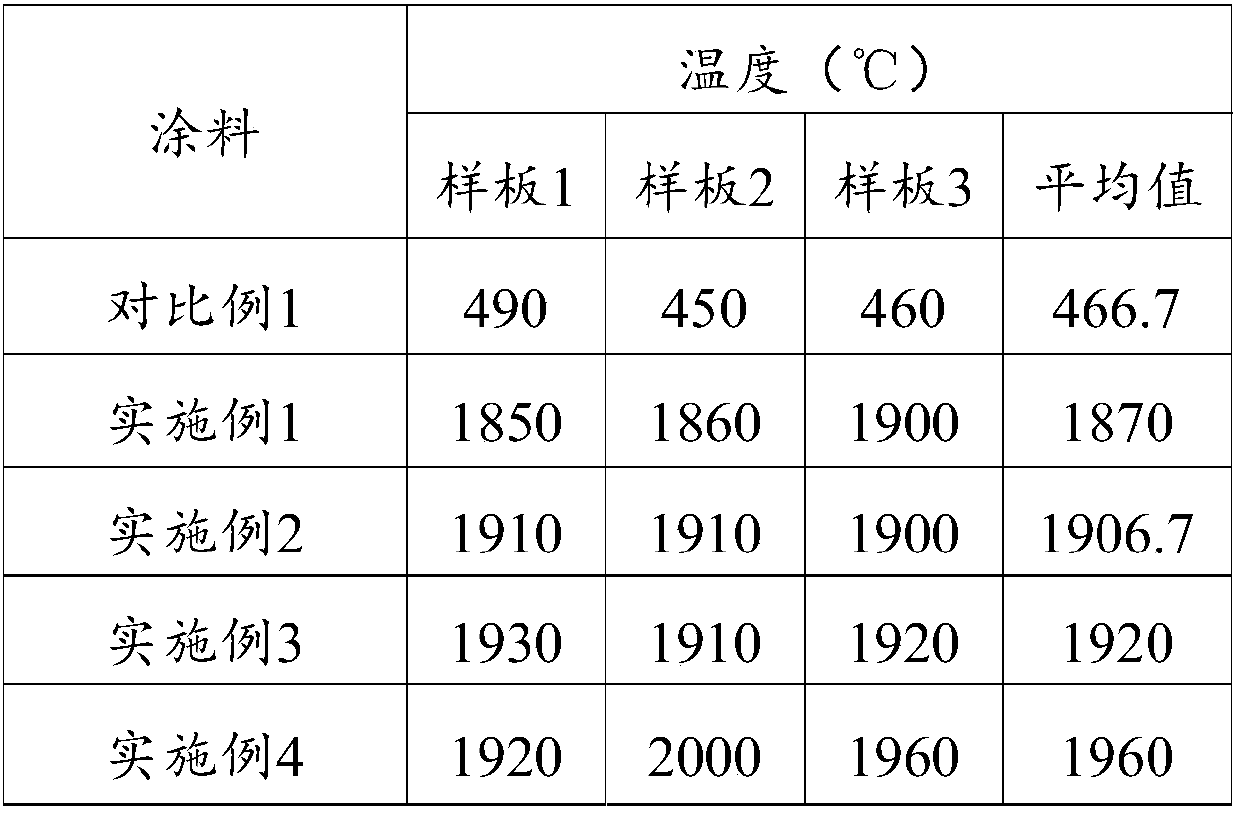

Graphene-based high-temperature-resistant anticorrosive paint and preparation method thereof

ActiveCN111057438AImprove high temperature and corrosion resistanceHigh elongation at breakFireproof paintsAnti-corrosive paintsBlack ferric oxideOrganosilicon

The invention relates to a graphene-based high-temperature-resistant anticorrosive paint and a preparation method thereof, and belongs to the technical field of anticorrosive materials, wherein the graphene-based high-temperature-resistant anticorrosive paint is obtained by mixing a component A and a component B according to a mass ratio of 9:1; the component A comprises the components in percentage by mass: 50 to 70% of a binding agent and 30 to 50% of a pigment filler; the binding agent comprises the components in percentage by mass: 60% of polymethylphenyl siloxane modified epoxy resin and40% of organic silicon; the pigment filler comprises the following components: graphene, chromium dioxide, titanium dioxide, zinc oxide, alumina powder, barium sulfate, magnesium carbonate, calcium carbonate, white carbon black micro-powder, quartz powder, graphite powder, green silicon carbide micro-powder, silicon carbide micro-powder, corundum micro-powder, silica powder, organic bentonite, mica powder and the balance being copper chromite black, iron oxide black and carbon fibers; and the component B is a curing agent. The anticorrosive paint has good comprehensive performance, strong corrosion resistance and high temperature resistance, and good comprehensive performance.

Owner:广东阿尔法工程材料有限公司

High temperature corrosion resistant ceramic coating for protecting float glass tin bath pendant and preparation method

The invention discloses a ceramic coating capable of resisting high-temperature corrosion for protecting a hanging part in a tin bath of float glass and a preparation method thereof. The preparation method comprises: dispersing SiO2, FeO, TiO2, Cr2O3, NiO, CoO and alkali metal compounds in water to obtain slurry with a solid content of 50-70%, grinding the slurry with a ball milling method to obtain an abrasive, then applying the abrasive on the cleaned surface of the hanging part and then sintering the surface of the hanging part and the coating. The resulting high-temperature ceramic coating has high-temperature anti-oxidation capacity and can also effectively improve the corrosion resistance of the surface of a Ni-Cr high-temperature alloy; and in addition, the ceramic coating can act as a heat barrier coating, forms effective protection on the hanging part in the tin bath of the float glass, and has important practical significance in prolonging the service life of the hanging part in the tin bath of the float glass.

Owner:武汉长利新材料科技有限公司 +1

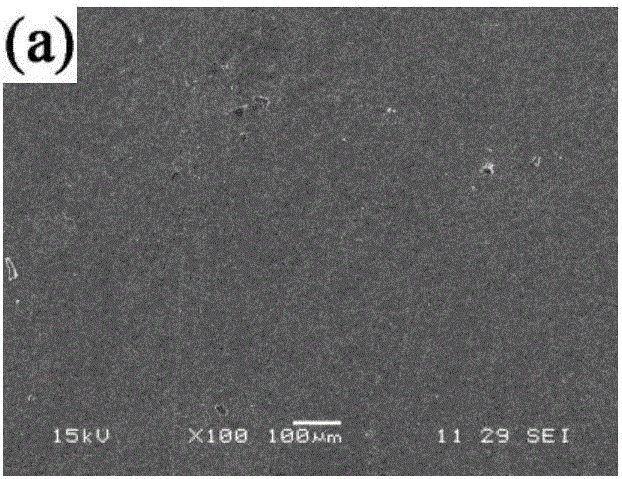

Wear-resisting and corrosion-resisting coating for boiler pipe wall and preparation method thereof

ActiveCN108517482ACoating structure refinementReduce porosityMolten spray coatingSurface engineeringRare-earth element

The invention discloses a wear-resisting and corrosion-resisting coating for a boiler pipe wall and a preparation method thereof and belongs to the technical field of surface engineering. According tothe method disclosed by the invention, a compound coating is formed by spraying powder on a base material (T91) through an active combustion high-velocity gas spraying technology (AC-HVAF); the powder is prepared from two components including Cr3C2-NiCr ceramic powder and CeO2 powder; the doping percent of the CeO2 powder is 0 to 20 weight percent and the balance is the Cr3C2-NiCr ceramic powder.The rare-earth element doped ceramic coating prepared by the method has dense tissues and the tissues are uniformly distributed; the coating has a flat structure and is tightly combined with the boundary of a matrix. Furthermore, the coating doped with the CeO2 powder, which is prepared by the method, has more dense tissues and the tissues are dispersed and distributed in the coating; the coatinghas higher corrosion resistance and high-temperature oxidization resistance, so that the anti-washout and abrasion-resisting performance and the high-temperature oxidization resistance of a boiler pipeline in an application process are easy to improve.

Owner:SOUTH CHINA UNIV OF TECH

Wear-resistant gear for high-speed gearbox

ActiveCN106282817BImprove heat resistanceAccelerated corrosionMolten spray coatingFoundry mouldsHeat resistanceMontmorillonite

The invention relates to an abrasion-resistant gear for a high-speed gear box. The abrasion-resistant gear comprises C, Cr, Si, Mn, Zn, Cu, Ag, Au, Pt, Ni, W, Mo, Nd, Ce, Eu, Lu, Ti, AlN, S, P, talc powder, magnesium oxide, tungsten carbide, montmorillonite and Fe. The abrasion-resistant gear for the high-speed gear box has the advantages that raw materials for the abrasion-resistant gear contain the Zn, the Ni and the W, and accordingly the heat resistance and the corrosion resistance of the gear can be improved.

Owner:南京创贝高速传动机械有限公司

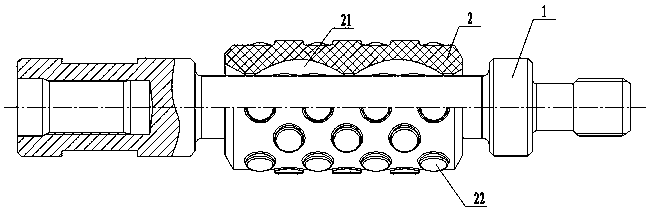

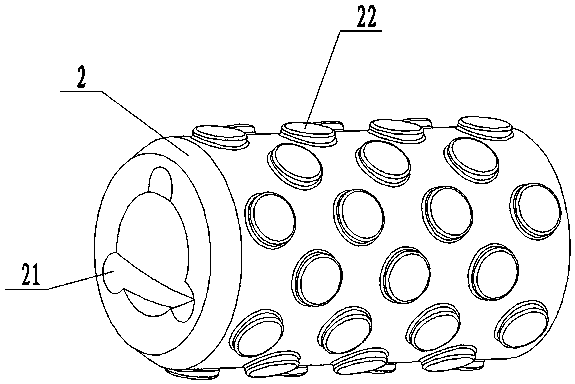

Anti-sulphuric wear-resistant sucker rod centralizer special for wax removal

PendingCN109931011AReduce up and down resistanceHigh strengthDrilling rodsCleaning apparatusWear resistantWax removal

The invention discloses an anti-sulphuric wear-resistant sucker rod centralizer special for wax removal. The anti-sulphuric wear-resistant sucker rod centralizer special for wax removal comprises a metal rod body and a cylindrical synthetic centralizing body rotatably arranged on the metal rod body, wherein three inner diversion screw-type overflowing holes are evenly formed in an inner wall of the cylindrical synthetic centralizing body, and a plurality of cylindrical flat bosses are evenly arranged on an outer surface of the cylindrical synthetic centralizing body. The anti-sulphuric wear-resistant sucker rod centralizer special for wax removal has the advantages that a cylindrical overall structure is adopted for the synthetic centralizing body, and the cylindrical body is provided withthe small bosses which are evenly distributed so that wax stone on an inner wall of an oil pipe can be conveniently cleared when a sucker rod moves vertically. The three evenly-distributed inner diversion screw-type overflowing holes in the inner wall of the synthetic centralizing body are designed, when overflowing crude oil passes through the inner diversion screw-type overflowing holes, screwstructures generate rotating force, the centralizing body is pushed to rotate on the metal rod body, wax on the inner wall is removed without dead angles, and not only can an effect of reducing upperand lower resistance of the sucker rod be achieved, but also even wear of the centralizing body can be guaranteed.

Owner:YANCHENG HUAYA GASOLINEEUM MACHINERY MFG

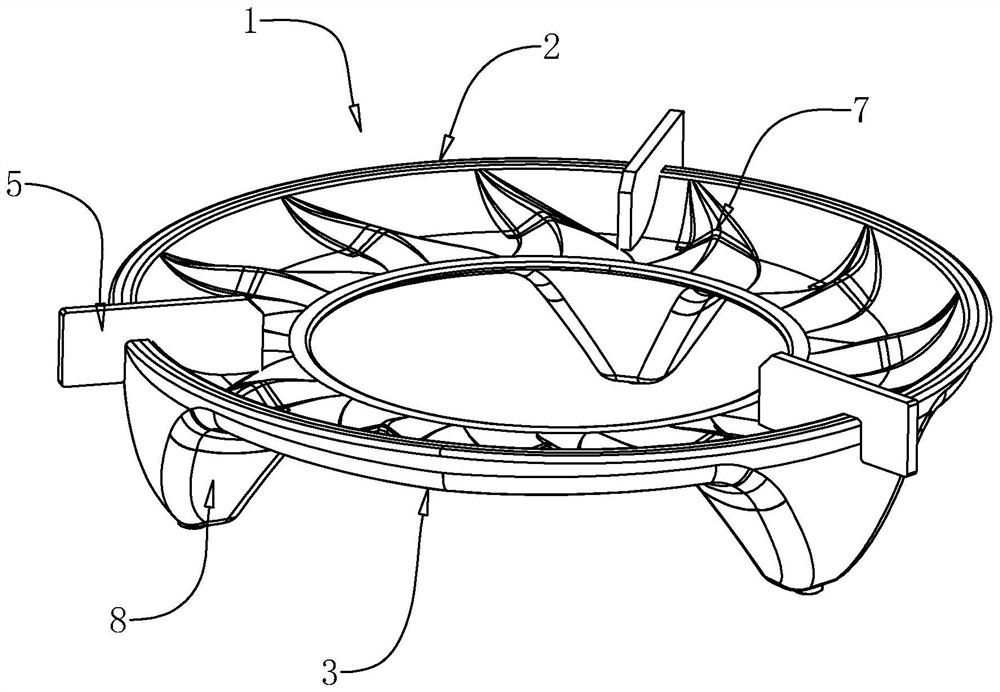

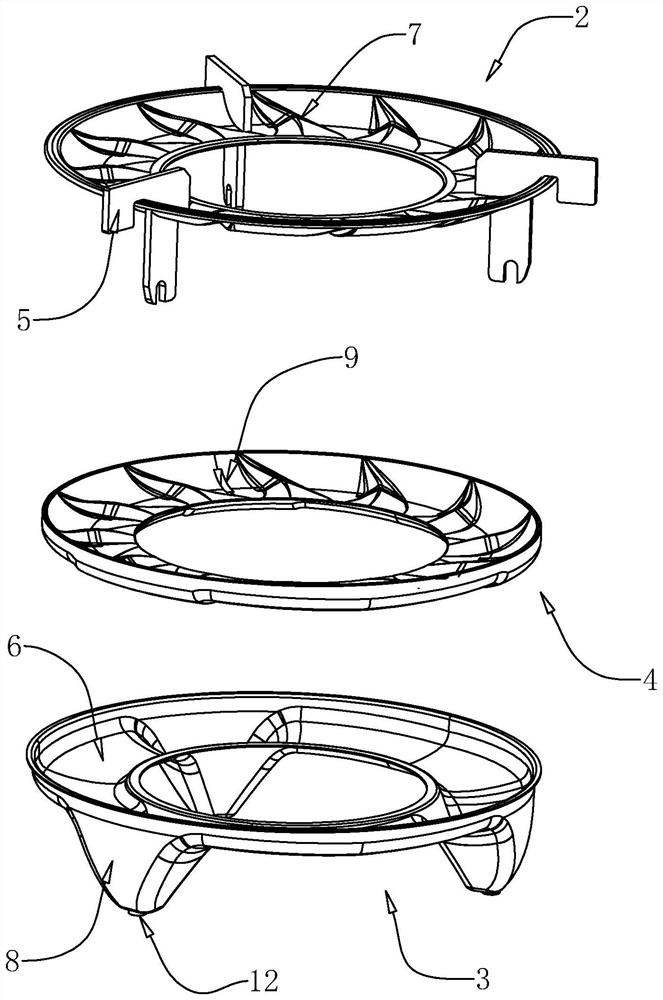

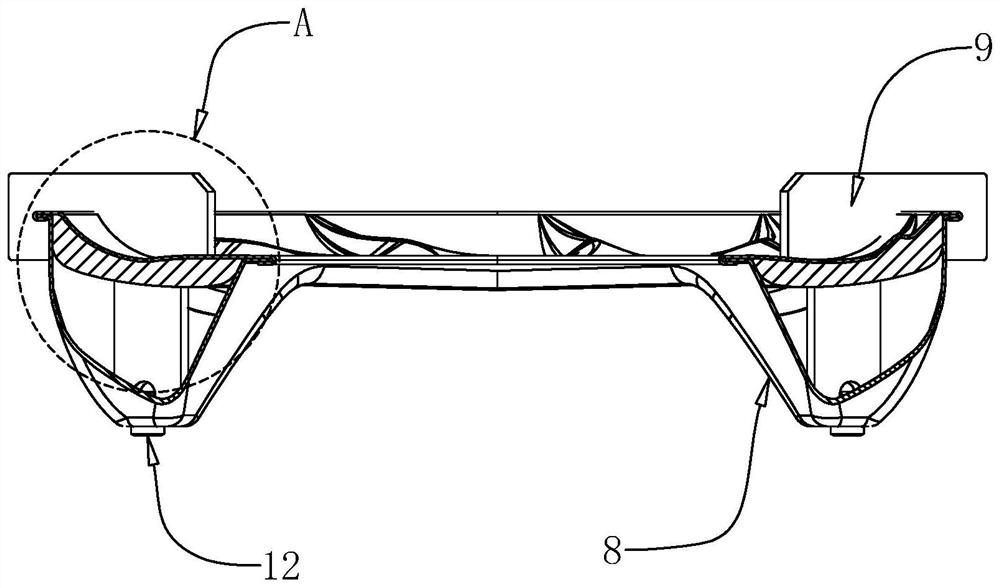

Energy-gathering and heat-insulating pot rack and production process thereof

ActiveCN114260653AJiaju energy insulation effectImprove high temperature and corrosion resistanceStoves/ranges topsInsulation layerCombustor

The invention relates to a production process of an energy-gathering and heat-insulating pot rack. The production process comprises the following steps: 1, respectively forming an upper cover disc and a lower cover disc of the pot rack through a mold; secondly, a heat insulation layer is formed through die stamping; thirdly, the lower ends of a plurality of supporting lugs penetrate through the upper cover disc and extend to the position below the lower cover disc, and then the supporting lugs are welded and fixed; fourthly, a heat insulation layer is placed on the lower cover disc, the upper cover disc is installed on the lower cover disc in a covering mode, a hollow heat insulation cavity is formed, and the heat insulation layer is located in the heat insulation cavity; and 5, forming an enamel coating or a high-temperature paint coating on the surface of the pot rack through a spraying process. The energy-gathering and heat-insulating effects of the pot rack are improved, and the combustion efficiency of the combustor is improved.

Owner:广东思利科智能科技有限公司 +1

A thermal recovery well cement stone high temperature water humidity curing simulation test device and method

ActiveCN109030140BUHT meetsMeet the wet environmentPreparing sample for investigationMaterial strength using tensile/compressive forcesThermodynamicsEngineering

The invention discloses a high-temperature water-wet maintenance simulation test device and method of cement stone of a thermal production well. The device is mainly composed of a nitrogen source (1),an intermediate water container (5), a CO2 gas source (10), a flowmetre (12), a closed kettle body A (13), a pressure gage (17), a condenser (19) and a heating furnace (22); cement stone (24) is putin the closed kettle body A (13); the closed kettle body A (13) is in the heating furnace (22); a water inlet is at the lower part of the side part of the kettle body A; the water inlet is separatelyconnected to the flowmetre (12) and a heating pressure manifold (11); the heating pressure manifold (11) is connected to the intermediate water container (5) and the nitrogen source (1), and also connected to the CO2 gas source (10); a water outlet is at the upper part of the side end of the kettle body A; the water outlet is connected to the pressure gage (17) and the condenser (19); the maintenance method can be used for simulating acid medium corrosion of cement stone of the thermal production well at different temperatures; and, if the closed kettle body A (13) is replaced by a closed kettle body B (25), the method can be used for testing the shear cementing strength and the channeling pressure of the cement stone in a high-temperature water-wet environment. The high-temperature water-wet maintenance simulation test device and method in the invention are reliable in principle and simple and convenient to operate, and have wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Nickel-based alloy surfacing welding process for alloy tank

ActiveCN110216360BLow dilution rateImprove high temperature and corrosion resistanceArc welding apparatusWelding defectMetal

The invention relates to a nickel-based alloy surfacing welding process for an alloy tank. The welding process adopts a cold metal transition welding method, and the welding process uses molten electrode gas for shielded welding. When in use, the welding process of nickel-based alloy surfacing welding is carried out by cold metal transition welding, which greatly reduces the dilution rate of the surfacing welding surface, improves the high temperature resistance and corrosion resistance of the material, and saves welding materials. At the same time, the welding process adopts at least two multi-pass welding methods to fill the alloy tank, which can solve welding defects such as incomplete fusion and missing welding during welding, and ensure welding quality.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所) +1

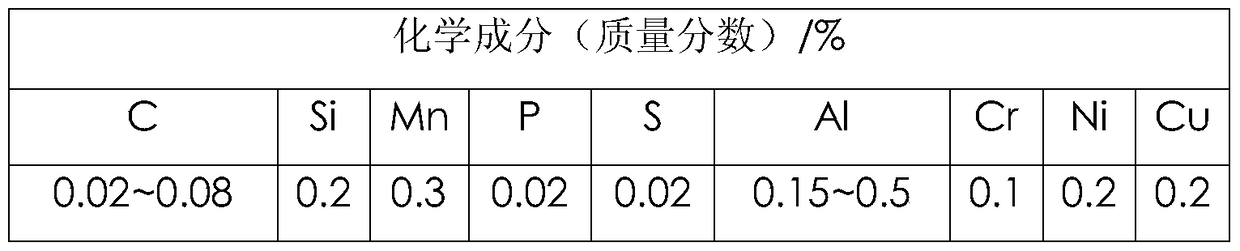

A high conductivity prebaked anode steel claw

The invention relates to an aluminum electrolysis prebaked anode steel claw and belongs to the technical field of electrolytic aluminum industry, and particularly provides a novel high-conductivity prebaked anode steel claw which is good in conductivity, low in cost, small in deformation and long in service life. The novel high-conductivity prebaked anode steel claw comprises a cross beam, a claw head and a welding line. The material of the cross beam or the claw head is low-carbon low-silicon non-oriented electrical steel or other high-conductivity steel, and the cross beam and a steel claw are connected by consumable electrode mixed gas arc welding. According to the invention, through optimal selection of the cross beam and the claw head and selection of a proper welding process, anode drop is remarkably reduced, the electrical conductivity and the flexural behavior of the steel claw are improved, and the life of the anode steel claw is effectively prolonged, and therefore, economic benefit is improved.

Owner:WUHAN UNIV

An oil baffle for a high-speed gearbox breather cap

ActiveCN106498259BImprove heat resistanceAccelerated corrosionMolten spray coatingFerric hydroxideKaolin clay

The invention relates to an oil baffle plate for a high-speed gear case vent cap. The oil baffle plate comprises tungsten carbide, montmorillonite, kaolin, bone black, aluminum oxide, magnesium oxide, copper oxide, ferric oxide, AlN, wollastonite, diopside, talcum powder, an anti-aging agent RD, Fe, ferric hydroxide, Al, Zn, Mn, Cr, Ni, Cu, Mo, Ti, Pd, Pt, W, Ce, Eu, Lu, Au, Ag, Sn, Zr, Re and clay. According to the oil baffle plate for the high-speed gear case vent cap, both the bone black and metal raw materials are added into the raw materials, so that the structural strength of the oil baffle plate is improved, heat dispersion of the oil baffle plate is also greatly strengthened compared with that of a pure ceramic material, the condensation efficiency is improved, and thus the oil baffle efficiency of the oil baffle plate is also improved.

Owner:南京创贝高速传动机械有限公司

A high temperature and corrosion resistant sinking roller and its manufacturing method

ActiveCN110306143BReduce corrosion rateExtended service lifeHot-dipping/immersion processesMolten spray coatingStellite alloyMachining

The invention discloses a high-temperature-resistant and corrosion-resistant sinking roller and a manufacturing method thereof, which belong to the field of hot-dipping equipment. The high-temperature-resistant and corrosion-resistant sinking roller of the present invention includes a roller body and a roller shaft, the surfaces of the roller body and the roller shaft are both coated with a coating, and the coating material is made of raw materials with the following weight ratio: WC: 70~ 90 parts; Co: 8-15 parts; Cr 3 C 2 : 3 to 15 parts; the surface of the roller body is provided with grooves in the circumferential direction, and the bottom surface of the grooves is an arc transition surface; the roller body is made of 316L stainless steel; the roller shaft is made of stellite-chromium-cobalt alloy; the sinking roller of the present invention It is made by groove processing, pre-treatment, coating material preparation and supersonic flame spraying. The invention greatly slows down the corrosion speed of the sinking roller and effectively prolongs the service life of the sinking roller by spraying the coating material of specific composition on both the roller body and the roller shaft surface of the sinking roller.

Owner:MAANSHAN IRON & STEEL CO LTD

Impeller transmission structure of soldering tin stove

InactiveCN101296577AImprove wear resistanceIncrease elasticityPrinted circuit assemblingRubber ringImpeller

The invention relates to a soldering tin stove used for welding a PCB board, in particular to an impeller driving structure of the soldering tin stove. The structure comprises a motor and an impeller; driving wheels are arranged on a corresponding output shaft and a corresponding input shaft; leather belts are connected among the driving wheels; the leather belts are O-shaped rubber rings which are high-temperature resistant; the driving wheel comprises an inner wheel made of graphite and an outer wheel made of metal materials and used for wrapping the hub of the inner wheel. The structure of the invention effectively improves the influence of high temperature on the leather belts and a conveyor belt by changing the material of the leather belts and the driving wheels in the impeller driving structure, thus causing the driving of the motor to the impeller to be stable and guaranteeing the stability of tin wave generation and welding quality.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

A kind of high permeability ultrafiltration composite ceramic coating membrane and preparation method thereof

ActiveCN107519772BHigh selectivityImprove permeabilityUltrafiltrationIn situ polymerizationUltrafiltration

The invention relates to a highly-permeable ultrafiltration composite ceramic coating film and a preparation method thereof, and belongs to the technical field of film separation. The highly-permeable ultrafiltration composite ceramic coating film comprises a ceramic base film, wherein the surface of the ceramic base film is sequentially provided with a silane coupling layer, a polyimide layer from interior to exterior; the mass ratio of the ceramic base film to the silane coupling layer to the polyimide layer is 1:(0.001 to 0.005):(0.01 to 0.1). The highly-permeable ultrafiltration composite ceramic coating film has the advantages that hyperbranched polyamide-amide is used as a pore passage building template, polyimide is used as a separating film, and the polyimide is grafted to the surface of the ceramic film in a covalent way by in-situ polymerizing, so that the composite separating film can simultaneously reach the high-selectivity and high-permeability advantages of a polymer film and high temperature-resistant and corrosion-resistant advantages of an inorganic film; the pore passage size and structure of the commercial ceramic film are improved, and the good permeability of the separating film is realized.

Owner:佛山市维宁新材料有限公司

A kind of penetrating agent for surface modification of nickel-based alloy and its application method

ActiveCN106521405BImprove high temperature and corrosion resistanceImprove bindingSolid state diffusion coatingTO-18Surface modification

The invention relates to an impregnating layer for high temperature resistance and corrosion resistance surface modification of a nickel base alloy, and application of the impregnating layer. An impregnation agent comprises an Al-Y impregnation agent and a Cr-Y impregnation agent, wherein the Al-Y impregnation agent comprises the following components by weight percent: 10% to 15% of Al, 1% to 2% of Y2O3 and 6% to 10% of NH4Cl, and the balance being Al2O3; and the Cr-Y impregnation agent comprises the following components by weight percent: 12% to 18% of Cr, 1% to 2% of Y2O3 and 6% to 10% of NH4Cl, and the balance being Al2O3. A Cr-Al-Y composite impregnating layer can be prepared on the surface of the nickel base alloy through a two-step method by virtue of the impregnation agent, and the corrosion property of the obtained alloy is improved by 3 to 5 times compared with the corrosion property of a matrix alloy.

Owner:BEIFANG UNIV OF NATITIES

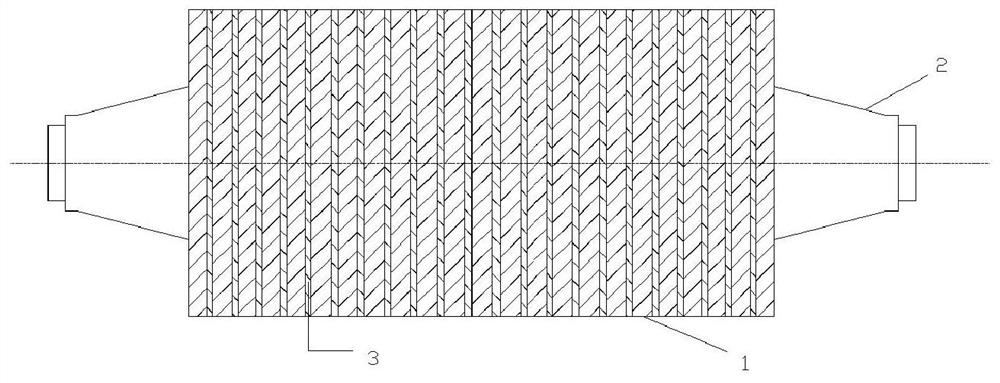

A kind of processing method of corrosion-resistant filler

ActiveCN104959104BImprove efficiencyImprove plasticityChemical/physical/physico-chemical processesUltimate tensile strengthMachining process

The invention discloses a processing method for a corrosion-resistant filler. The processing method comprises the steps of blending, crushing, mixing and ball grinding, water addition, clay preparation, forming, low-temperature drying, feeding into a kiln, firing and the like. According to the processing method, raw materials are mixed and ball-ground after being crushed in a filler processing process, so that crushing efficiency is improved, and the raw materials can be rapidly processed into required particle sizes; the surface of the filler is spray-coated with 1Cr13 and pure aluminum coatings, so that the corrosion resistance and the strength of the filler are further improved.

Owner:SUZHOU KD PETROCHEM ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com