A kind of high permeability ultrafiltration composite ceramic coating membrane and preparation method thereof

A technology of composite ceramics and ceramic membranes, applied in the field of membrane separation, can solve the problems of unfavorable separation membrane service life, low strength, weak binding force, etc., achieve low production cost, good comprehensive performance, and improve the effect of pore size and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

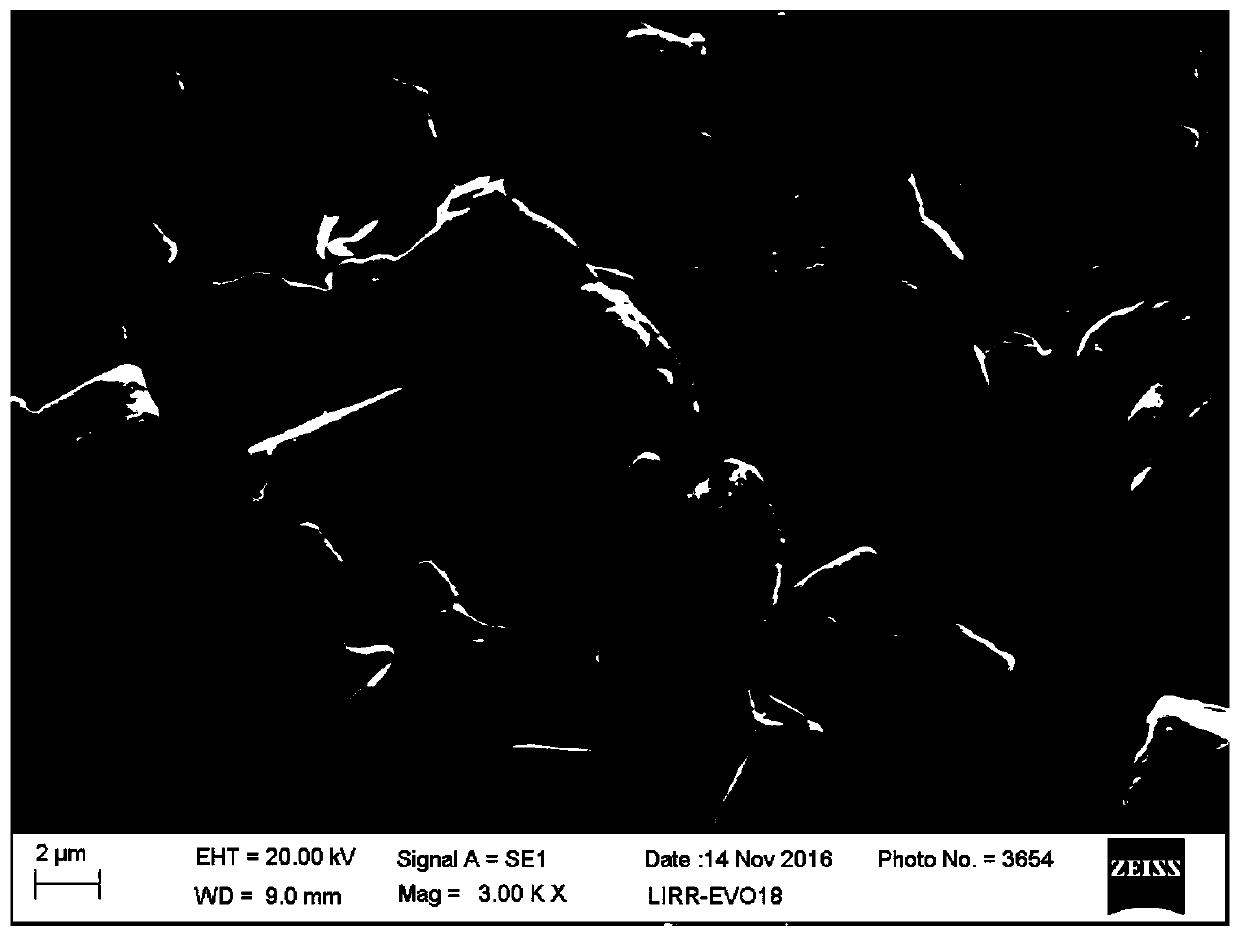

Embodiment 1

[0040] The high permeable ultrafiltration composite ceramic coating membrane of this embodiment comprises a ceramic base membrane, and the surface of the ceramic base membrane is sequentially provided with a silane coupling layer, a hyperbranched polymer layer, a polyimide layer, a ceramic base membrane, a silane The mass ratio of the coupling layer, hyperbranched polymer layer, and polyimide layer is 1:0.001:0.002:0.01; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethyl Oxysilane, hyperbranched polymer layer is 1 generation polyamido-amine.

[0041] The preparation method of the high permeability ultrafiltration composite ceramic coating membrane of the present embodiment comprises the following steps:

[0042] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultrasonic cleaner for 5 minutes, take it out and put it into a beaker fill...

Embodiment 2

[0048] The high permeable ultrafiltration composite ceramic coating membrane of this embodiment comprises a ceramic base membrane, and the surface of the ceramic base membrane is sequentially provided with a silane coupling layer, a hyperbranched polymer layer, a polyimide layer, a ceramic base membrane, a silane The mass ratio of the coupling layer, hyperbranched polymer layer, and polyimide layer is 1:0.005:0.002:0.05; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethyl Oxysilane, hyperbranched polymer layer is 1 generation polyamido-amine.

[0049] The preparation method of the high permeability ultrafiltration composite ceramic coating membrane of the present embodiment comprises the following steps:

[0050] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultrasonic cleaner for 10 minutes, take it out and put it into a beaker fil...

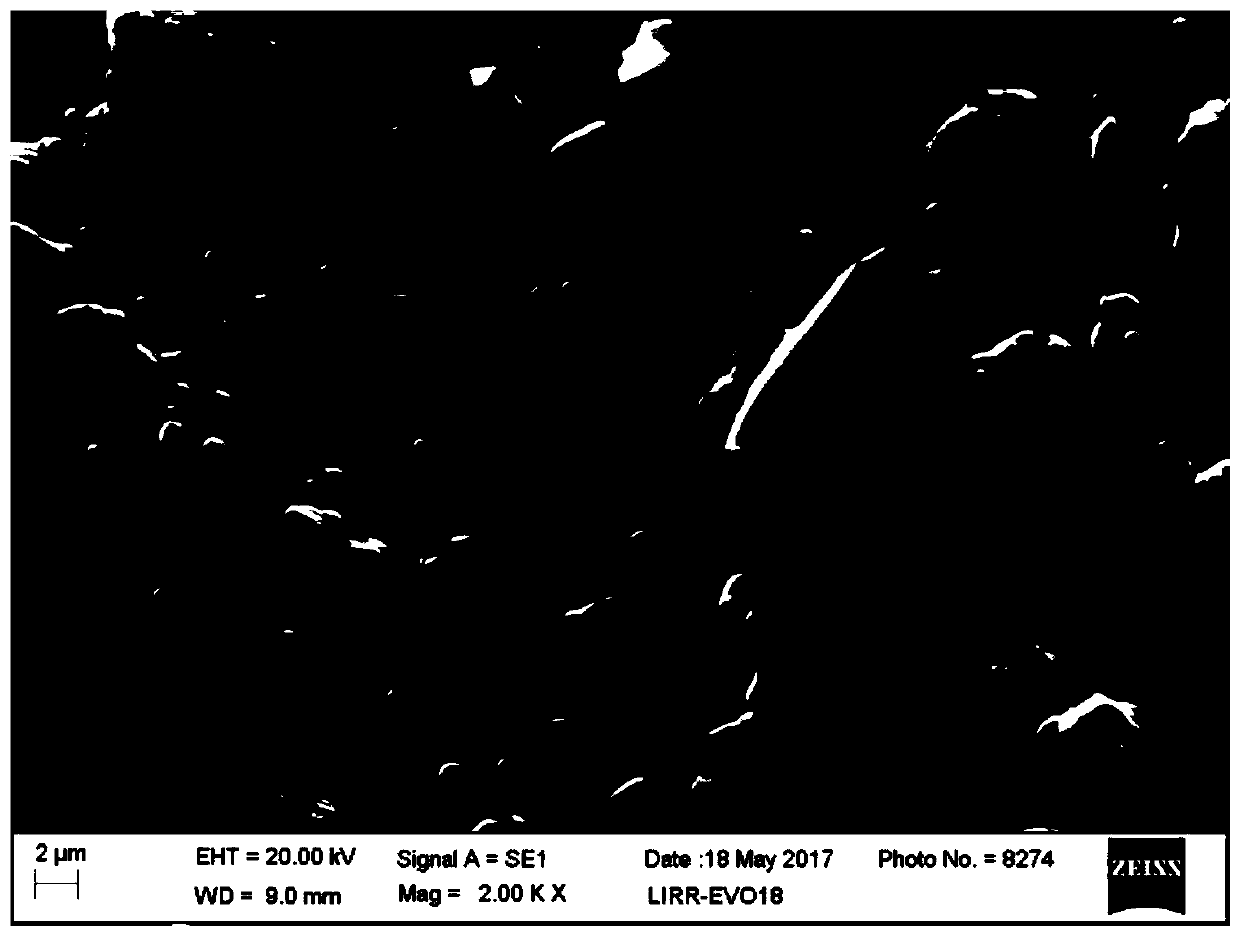

Embodiment 3

[0056] The high permeable ultrafiltration composite ceramic coating membrane of this embodiment comprises a ceramic base membrane, and the surface of the ceramic base membrane is sequentially provided with a silane coupling layer, a hyperbranched polymer layer, a polyimide layer, a ceramic base membrane, a silane The mass ratio of coupling layer, hyperbranched polymer layer, and polyimide layer is 1:0.003:0.002:0.03; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyl trimethyl Oxysilane, hyperbranched polymer layer is 1 generation polyamido-amine.

[0057] The preparation method of the high permeability ultrafiltration composite ceramic coating membrane of the present embodiment comprises the following steps:

[0058] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultrasonic cleaner for 7 minutes, take it out and put it into a beaker filled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com