Patents

Literature

40results about How to "Good high temperature and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

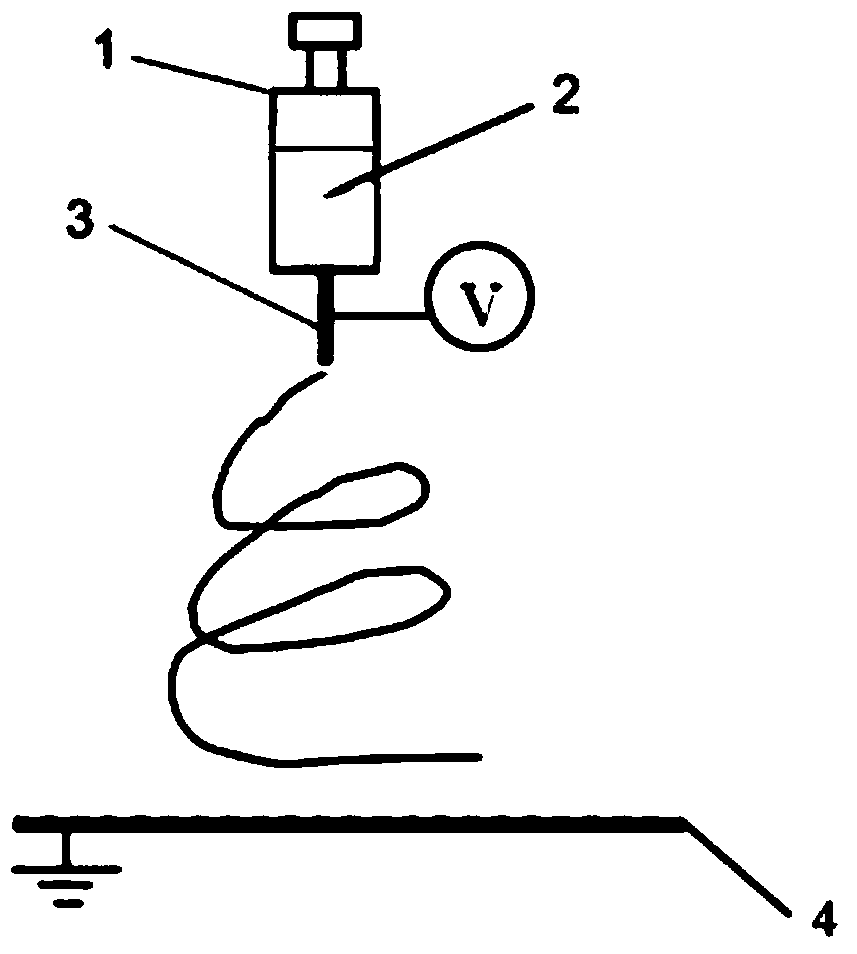

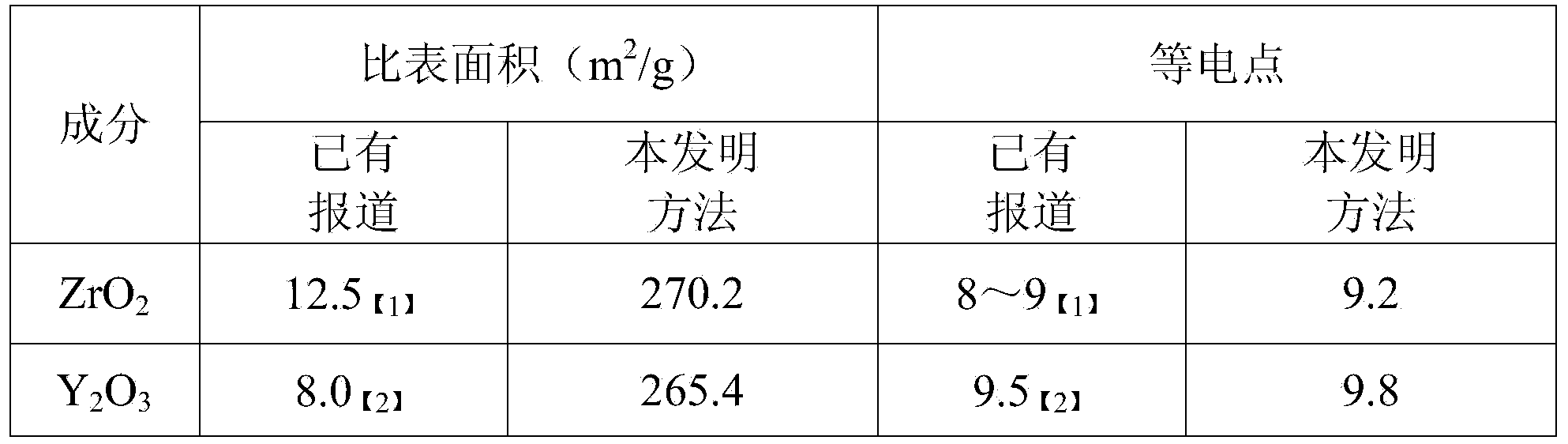

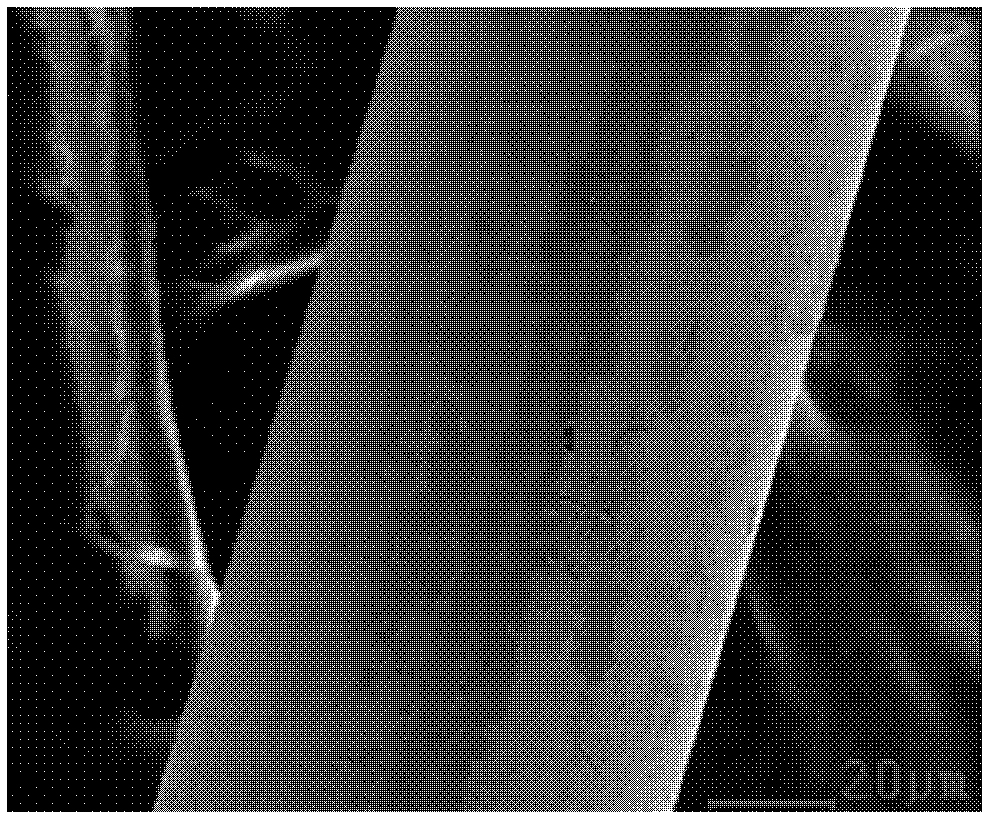

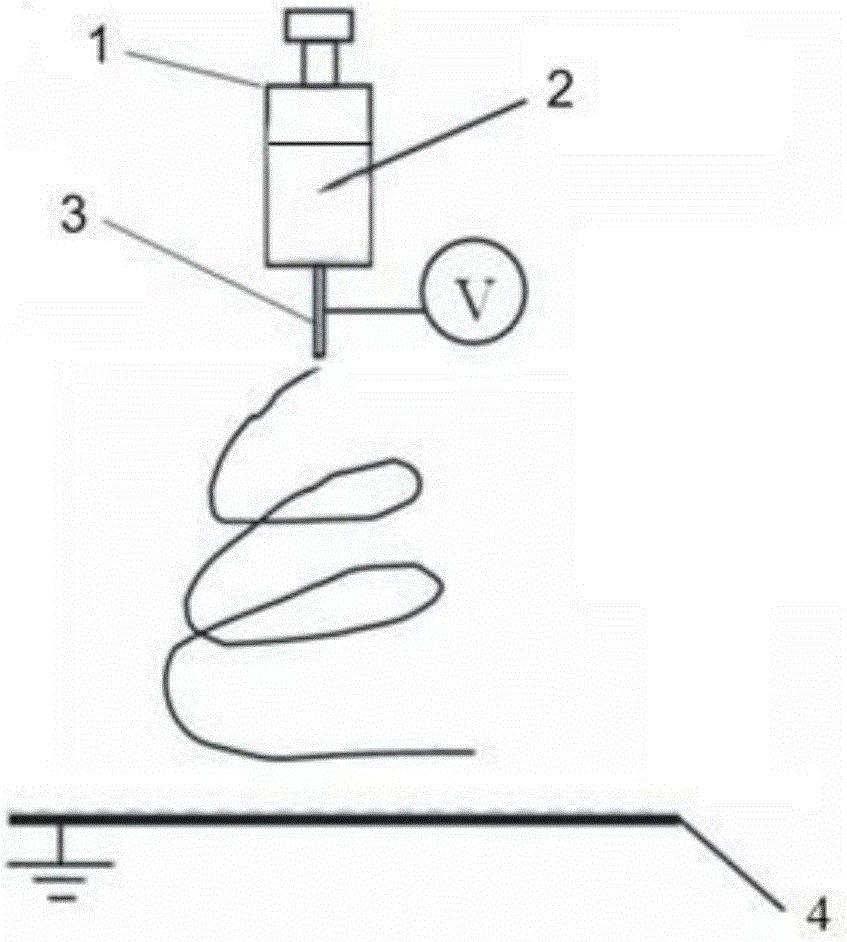

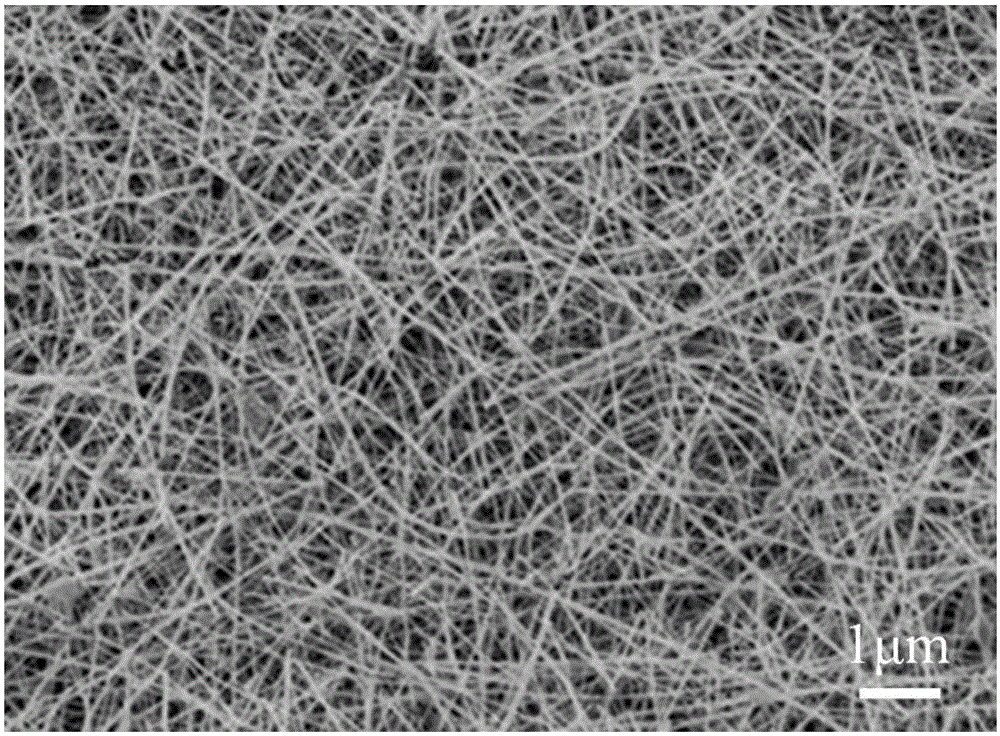

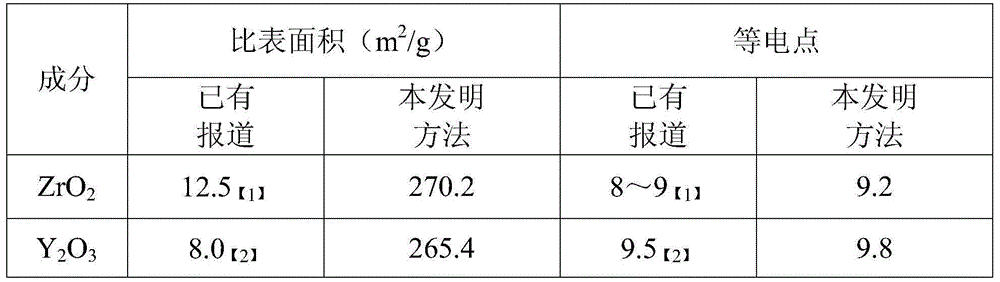

Preparation method of positively-charged ceramic micro-nano fiber membrane

InactiveCN103451850AHigh porosityLarge specific surface areaHeating/cooling textile fabricsNon-woven fabricsPorosityFiber

The invention discloses a preparation method of a positively-charged ceramic micro-nano fiber membrane. The preparation method comprises the steps of adding spinnable polymer in a solvent, then adding a ceramic precursor in the solvent, and obtaining spinning solution after stirring and aging; pouring the spinning solution in a micro pump, adopting an injection needle head which is scraped smoothly as a spray nozzle, and obtaining composite fiber through electrostatic spinning; firstly roasting the composite fiber in anoxic atmosphere at 200-500 DEG C, then roasting the composite fiber in inertia or reducing atmosphere at 400-400 DEG C for 1-5 hours, and obtaining the positively-charged ceramic micro-nano fiber membrane. According to the preparation method of the positively-charged ceramic micro-nano fiber membrane, disclosed by the invention, the positively-charged ceramic micro-nano fiber membrane which is prepared by combining the electrostatic spinning and a step-by-step roasting technology has high porosity, high specific surface area, high surface electrical performance and good high-temperature-resisting and corrosion-resisting performances, has great advantages of separating, shielding and removing bacteria and virus and has a wide application prospect in environment cleaning, pharmaceuticals production, bioengineering, foundation medicine and the like.

Owner:XIAN UNIV OF TECH

High-performance alloy wire brush used for brush seal, and preparation method thereof

InactiveCN103160709AHigh strengthGood high temperature and wear resistanceMaterials processingLow density

The invention discloses a high-performance alloy wire brush used for a brush seal of an engine, and a preparation method thereof, and belongs to the material processing field. The components of the alloy brush comprise 16-20% of Cr, 2.5-3% of Mo, 8-10% of Co, 1-3% of Fe, 0.2-1% of Ti, 0.4-1.5% of Al, 0.05-0 .1% of C, and the balance being Ni. The preparation method of the alloy brush comprises the steps of mixing the raw materials according to a mass percentage, vacuum melting, wherein low density metals such as Ti, Al and the like are added in forms of intermediate alloys of NiTi and NiAl, Mo is added in a form of MoFe; then rolling into alloy rods by forging; multi-pass drawing annealing, and making into alloy wires with diameter of 0.08-0.4 mm.. The alloy wire brush has relatively good anti-high temperature wear resistance, anti-high temperature corrosion resistance, oxidation resistance and relatively high strength. As a wire brush material for the brush seal of the engine, the service life and reliability of the brush seal of the engine can be effectively increased.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

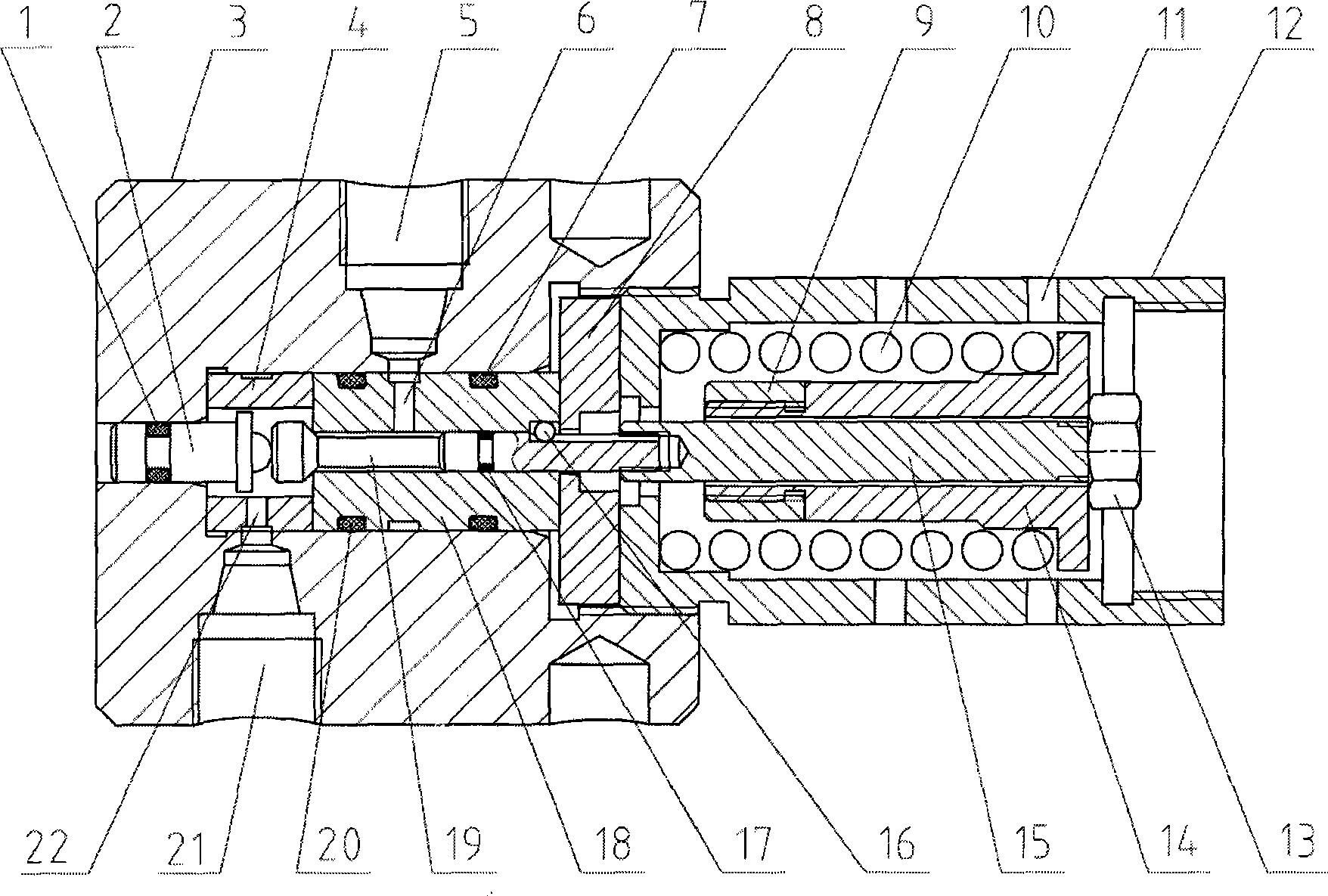

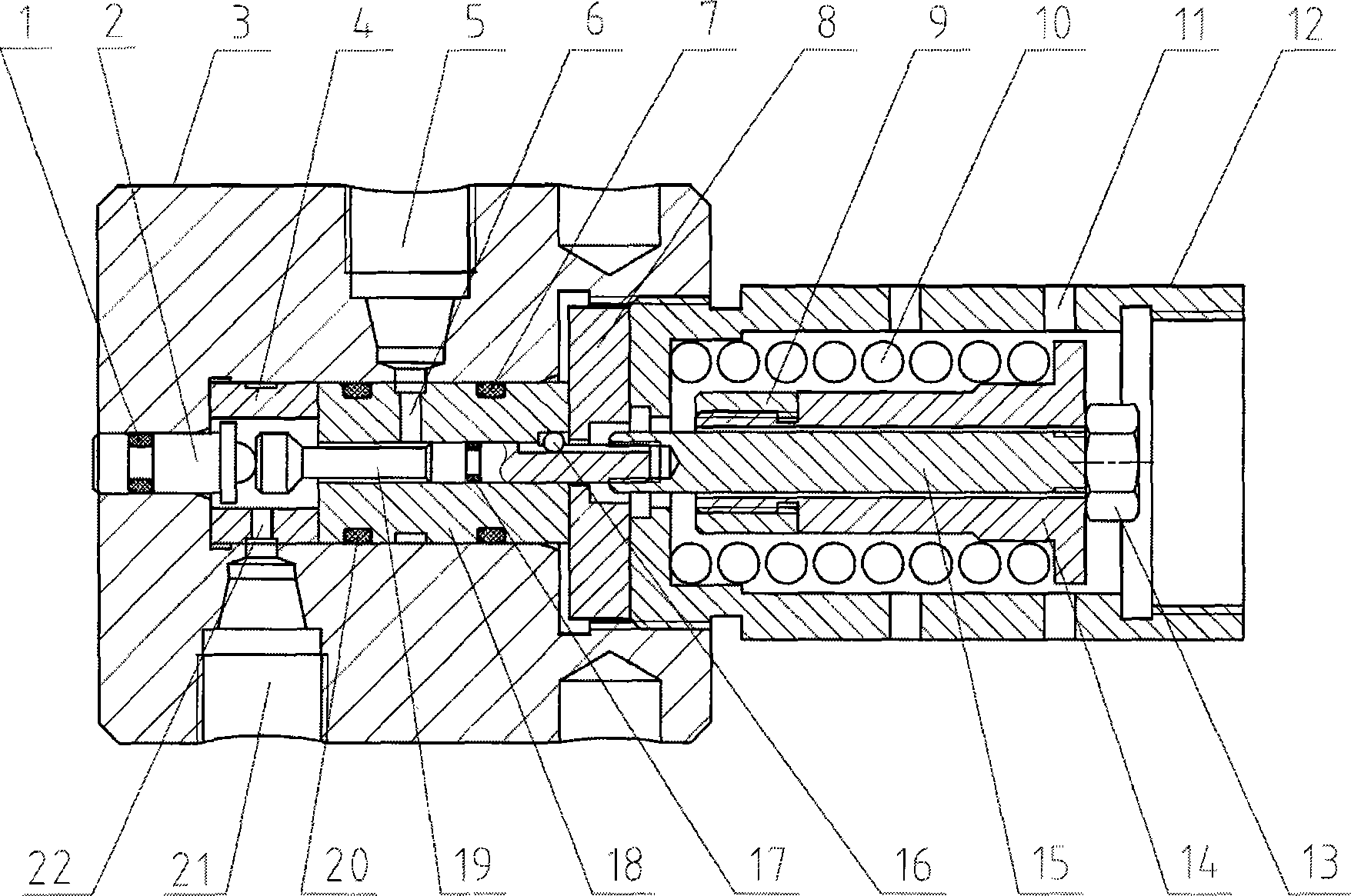

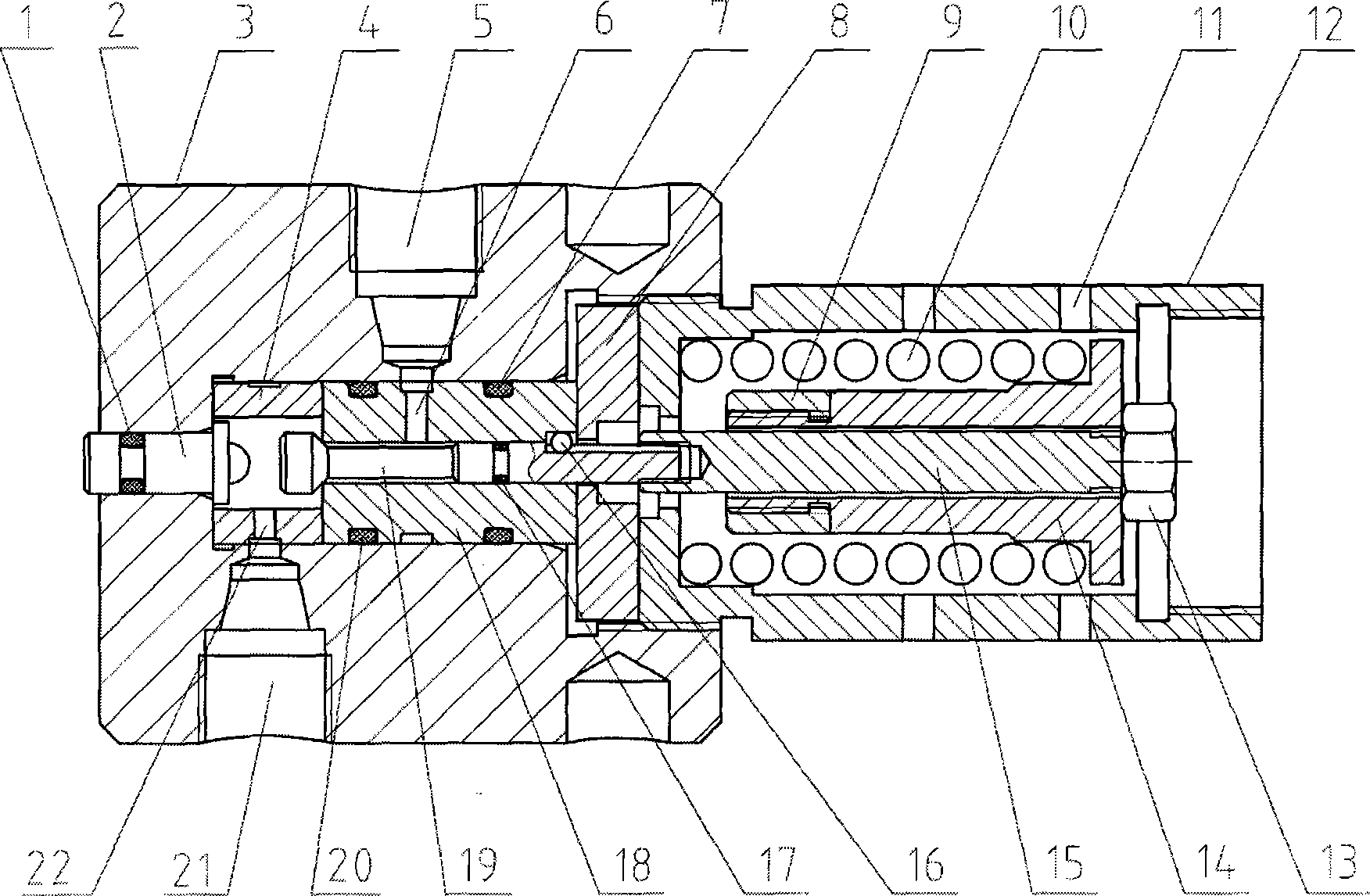

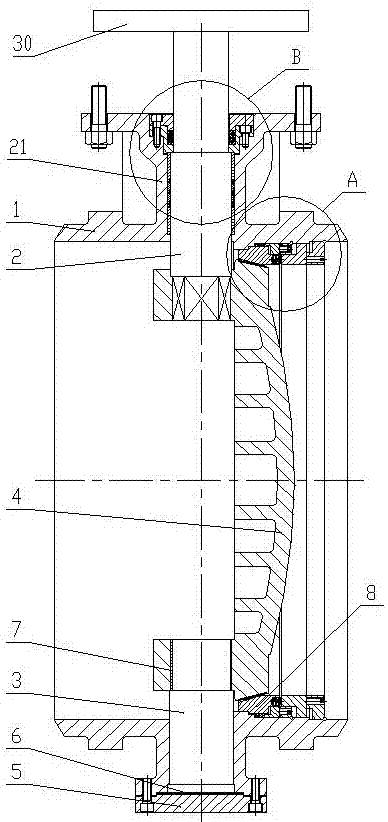

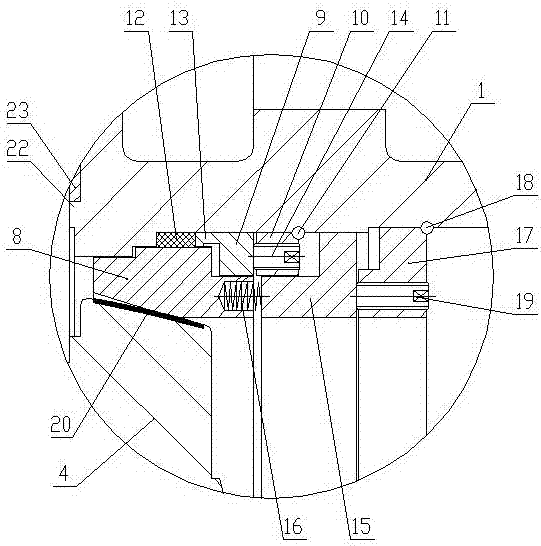

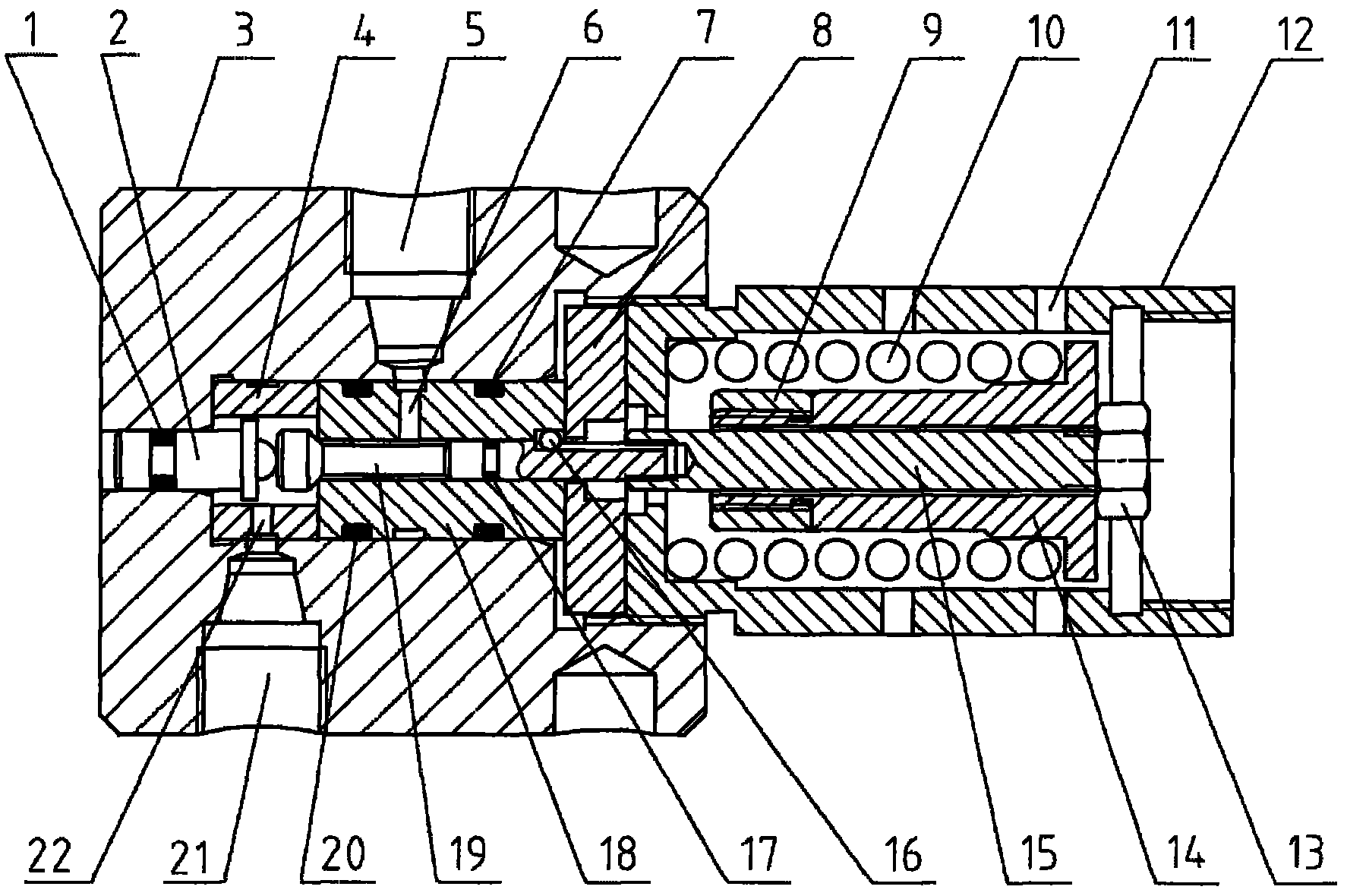

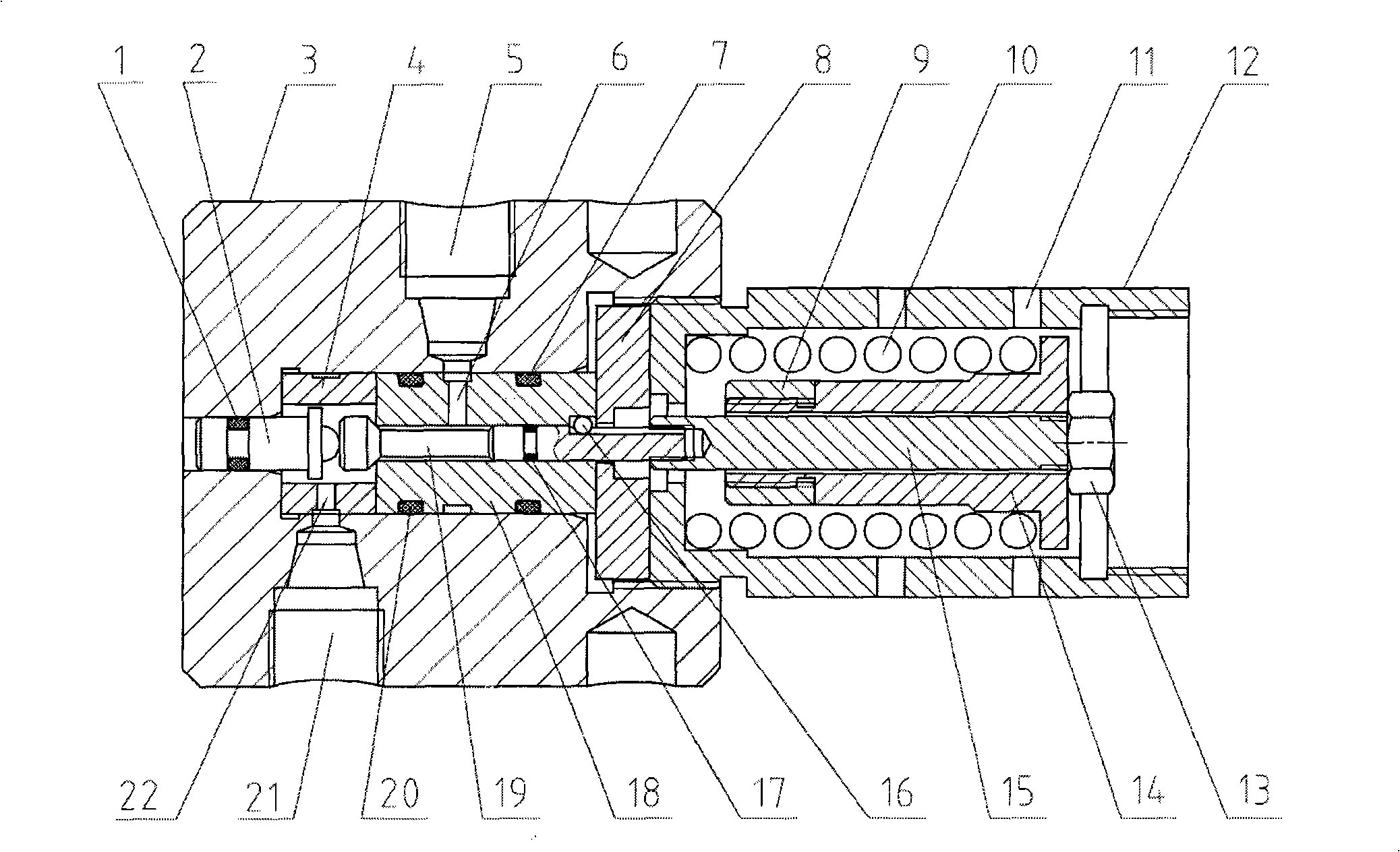

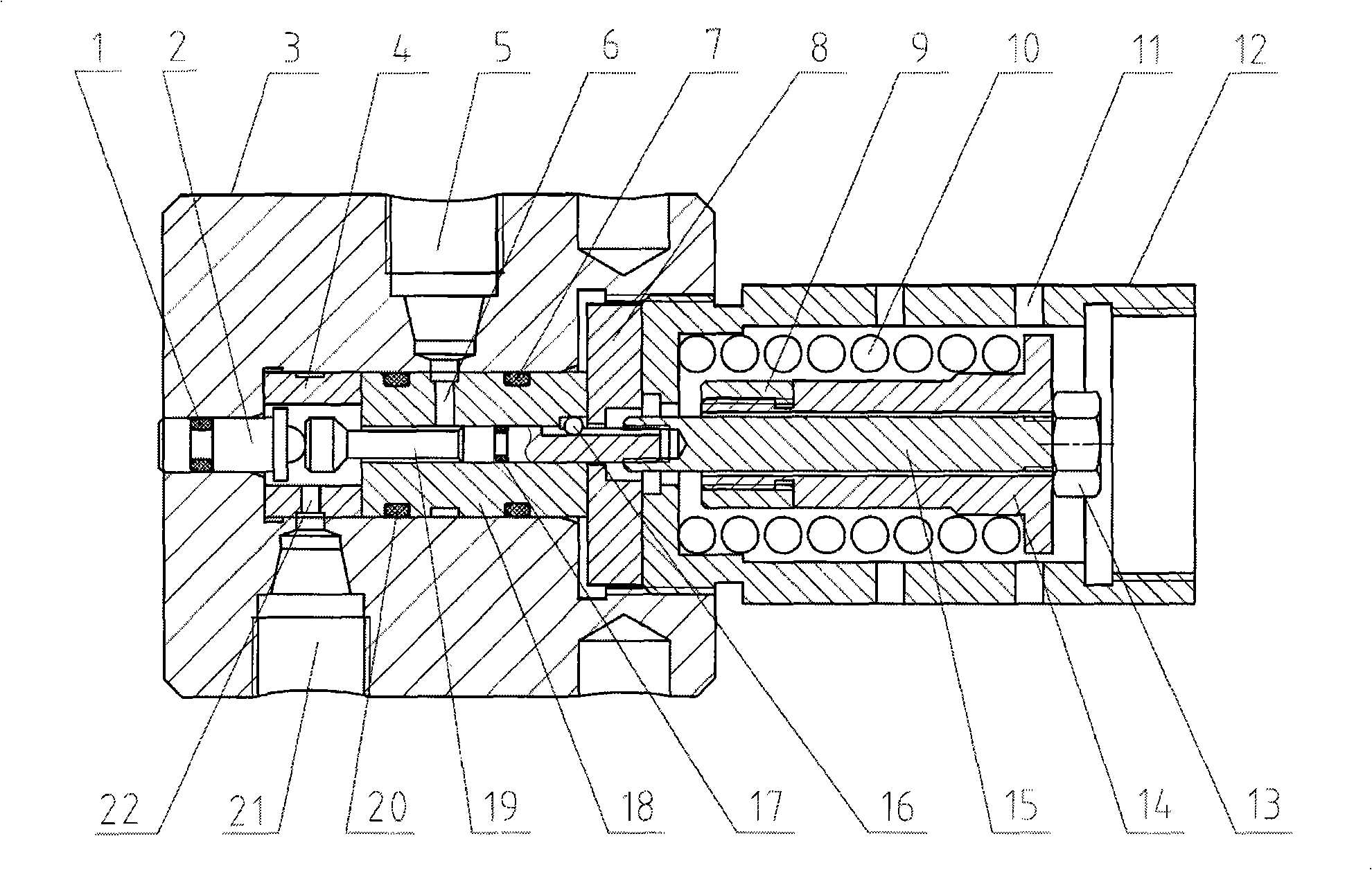

High-temperature high-pressure sampling valve used for deep sea

InactiveCN101464229AImprove sealingGood high temperature and corrosion resistanceWithdrawing sample devicesEngineeringHigh pressure

The invention discloses a high-temperature high-pressure sampling valve used in deep water. The sampling valve mainly comprises a valve body, a valve housing, a first valve core, a second valve core, a spring cavity and a return spring. The invention has the two-way self-fastening sealing capacity due to the adoption of the structural manner of two valve cores, so that the sampling valve has excellent sealing performance under a high pressure. The sampling valve has superior high-temperature resistance and decay resistance, thereby improving the fidelity of thermal water samples. The sampling valve opens under linear driving, and closes automatically following the withdrawl of external driving force, thereby increasing the convenience of use in deep water.

Owner:ZHEJIANG UNIV

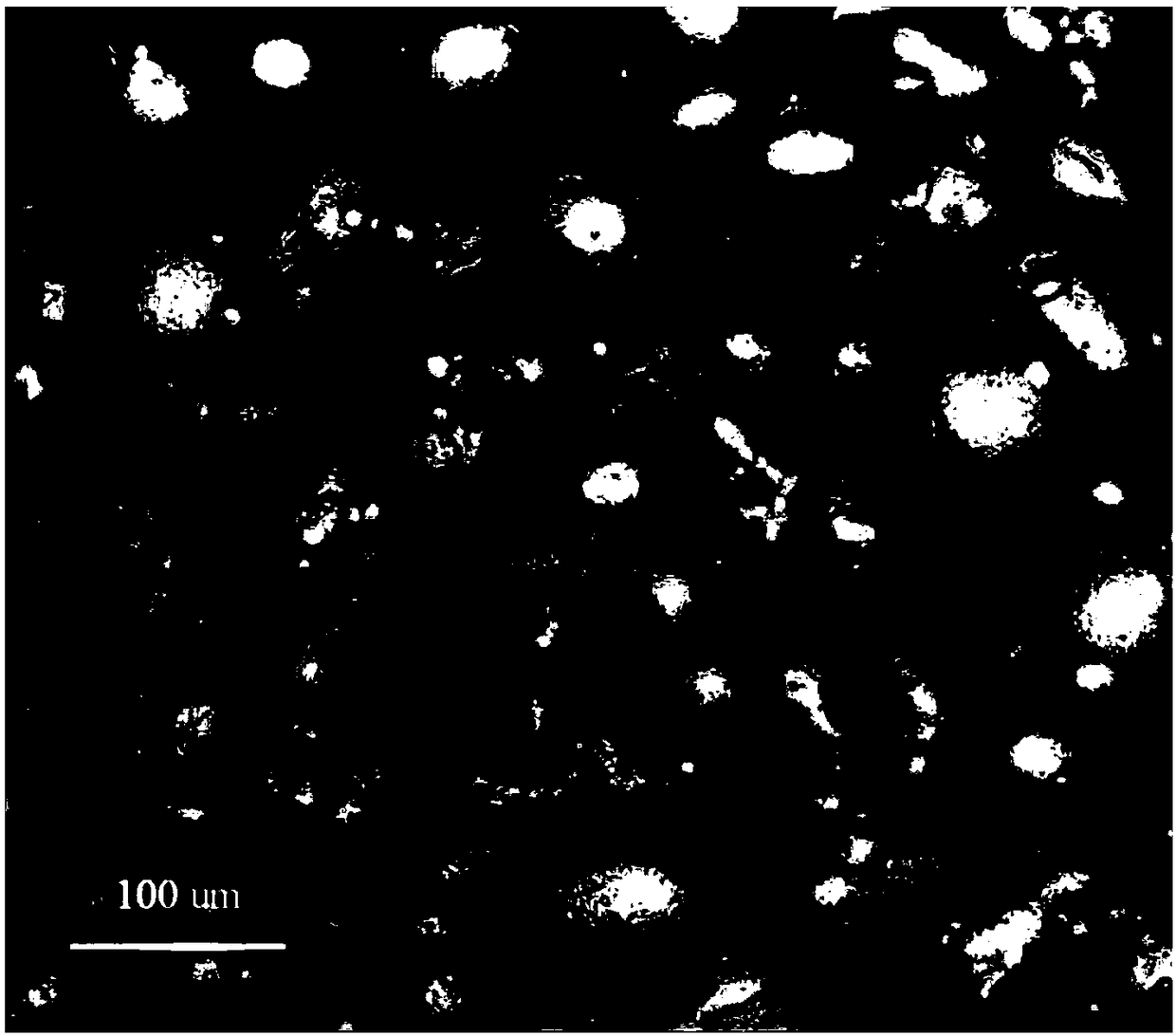

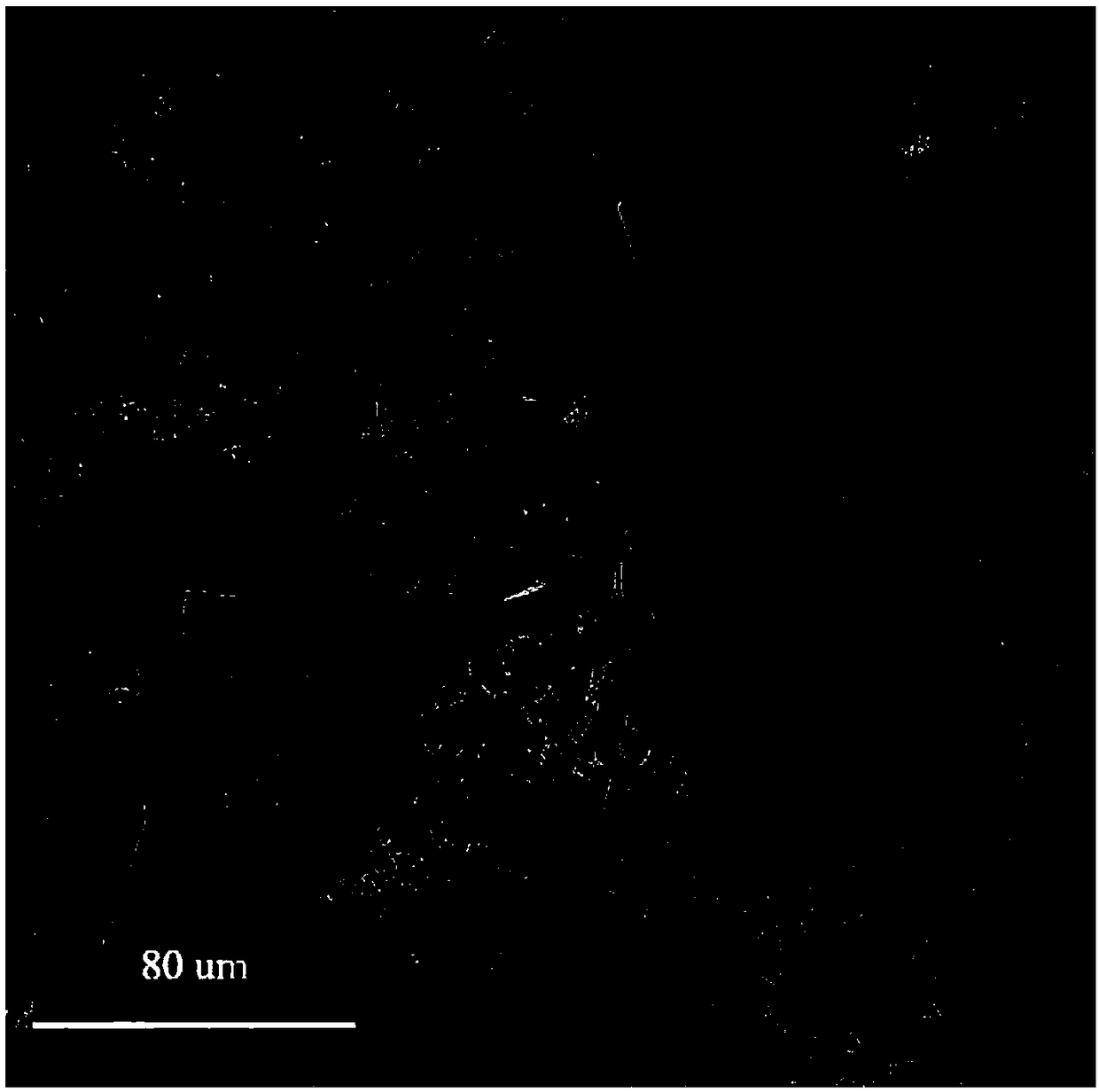

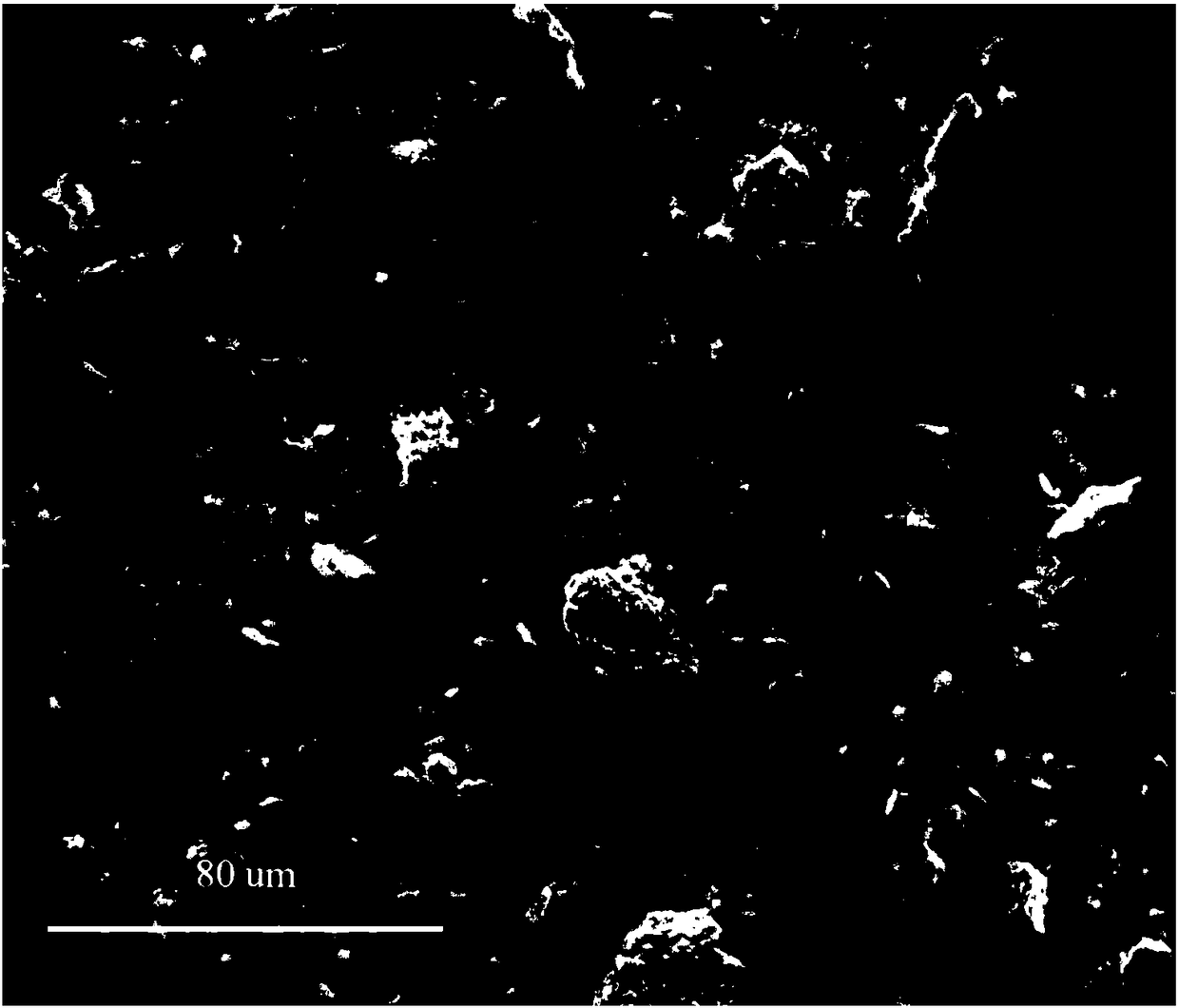

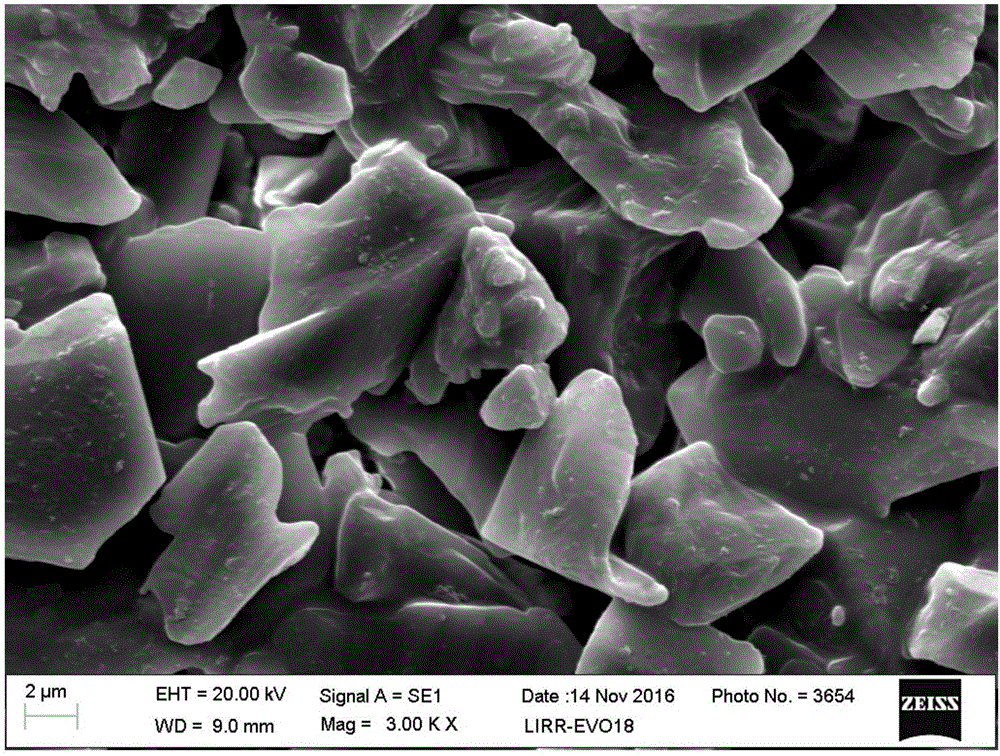

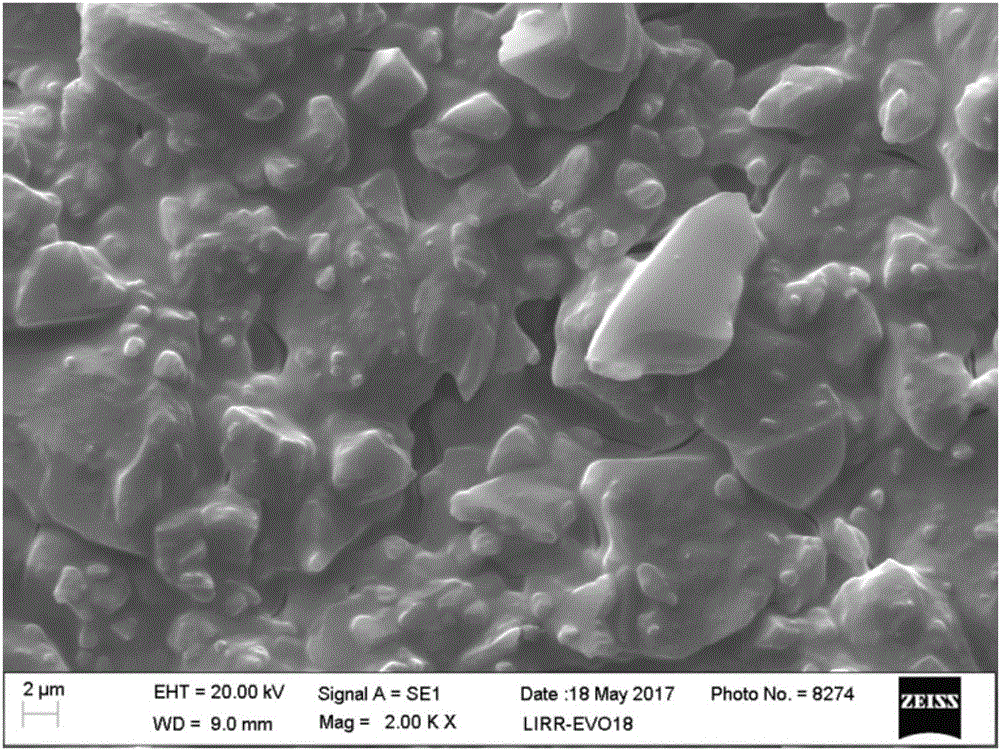

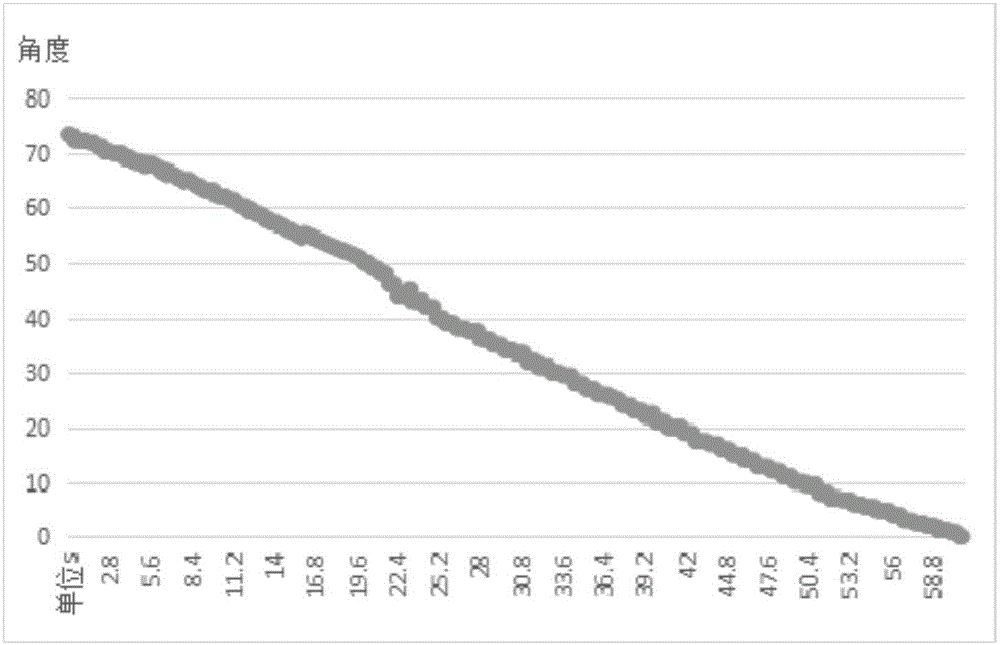

TiB2-Ni-based metal-ceramic composite feed for thermal spraying and preparation method of TiB2-Ni-based metal-ceramic composite feed

InactiveCN108356274AHigh sphericityImprove liquidityMolten spray coatingTransportation and packagingComposite constructionCeramic composite

The invention discloses TiB2-Ni-based metal-ceramic composite feed for thermal spraying and a preparation method of the TiB2-Ni-based metal-ceramic composite feed. The preparation method comprises thefollowing steps: (1) in a protective atmosphere, adding TiB2 powder and Ni-based alloy powder into a stirring grinder, adding a process control agent, a binding agent and a grinding medium, and thencarrying out grinding, so as to obtain slurry of composite powder A; (2) carrying out spray granulation on the slurry of the composite powder A in a spray drying system, so as to obtain composite powder B; (3) carrying out heat preservation on the composite powder B in drying equipment, so as to obtain composite powder C; and (4) passing the composite powder C through a spheroidizing system, so asto obtain high-sphericity composite powder. The powder prepared through the preparation method disclosed by the invention is high in flowability and excellent in performance; the demand of thermal spraying equipment for the powder flowability can be met; the problem that nanometer metal-ceramic composite powder is hard to spray can be solved; and the improvement of the coating surface performancecan be facilitated.

Owner:SOUTH CHINA UNIV OF TECH

Highly-permeable ultrafiltration composite ceramic coating film and preparation method thereof

ActiveCN107519772AImprove performanceSimple processUltrafiltrationComposite ceramicIn situ polymerization

The invention relates to a highly-permeable ultrafiltration composite ceramic coating film and a preparation method thereof, and belongs to the technical field of film separation. The highly-permeable ultrafiltration composite ceramic coating film comprises a ceramic base film, wherein the surface of the ceramic base film is sequentially provided with a silane coupling layer, a polyimide layer from interior to exterior; the mass ratio of the ceramic base film to the silane coupling layer to the polyimide layer is 1:(0.001 to 0.005):(0.01 to 0.1). The highly-permeable ultrafiltration composite ceramic coating film has the advantages that hyperbranched polyamide-amide is used as a pore passage building template, polyimide is used as a separating film, and the polyimide is grafted to the surface of the ceramic film in a covalent way by in-situ polymerizing, so that the composite separating film can simultaneously reach the high-selectivity and high-permeability advantages of a polymer film and high temperature-resistant and corrosion-resistant advantages of an inorganic film; the pore passage size and structure of the commercial ceramic film are improved, and the good permeability of the separating film is realized.

Owner:佛山市维宁新材料有限公司

Resistive layer and manufacturing method thereof

ActiveCN109321892AImprove thermal stabilityGood high temperature and corrosion resistanceChemical vapor deposition coatingElectrical resistance and conductanceEngineering

The invention relates to a resistive layer and a manufacturing method of the resistive layer. The component of the resistive layer is Ru:Al203. A deposition method of the Ru:Al203 atomic layer of theresistive layer comprises the main steps that (1) a base material is placed in an atomic layer deposition reactor; (2) N2 carrier gas carries Ru(Cp)2 into the reactor to be adsorbed to the surface ofthe base material, purging is conducted, O2 pulse enters the reactor, purging is conducted, then Ru film is generated, the N2 carrier gas carries Al(CH3)3 into the reactor to be adsorbed on the surface of the Ru film, purging is conducted, H2O pulse enters the reactor, purging is conducted, and then Al2O3 is generated; and (3) according to the needed resistance, the step (2) is repeatedly executed. The manufacturing method of the resistive layer can accurately adjust the doping ratio of the resistive layer so as to enable the resistive layer to meet the standard resistance range and has the advantages that the purity of the film is high, the film is dense and uniform, and the thickness of the film can be accurately controlled; and besides, no poisonous gas or hazardous gas is discharged, and batch production is easy to achieve.

Owner:XIAN MODERN CHEM RES INST

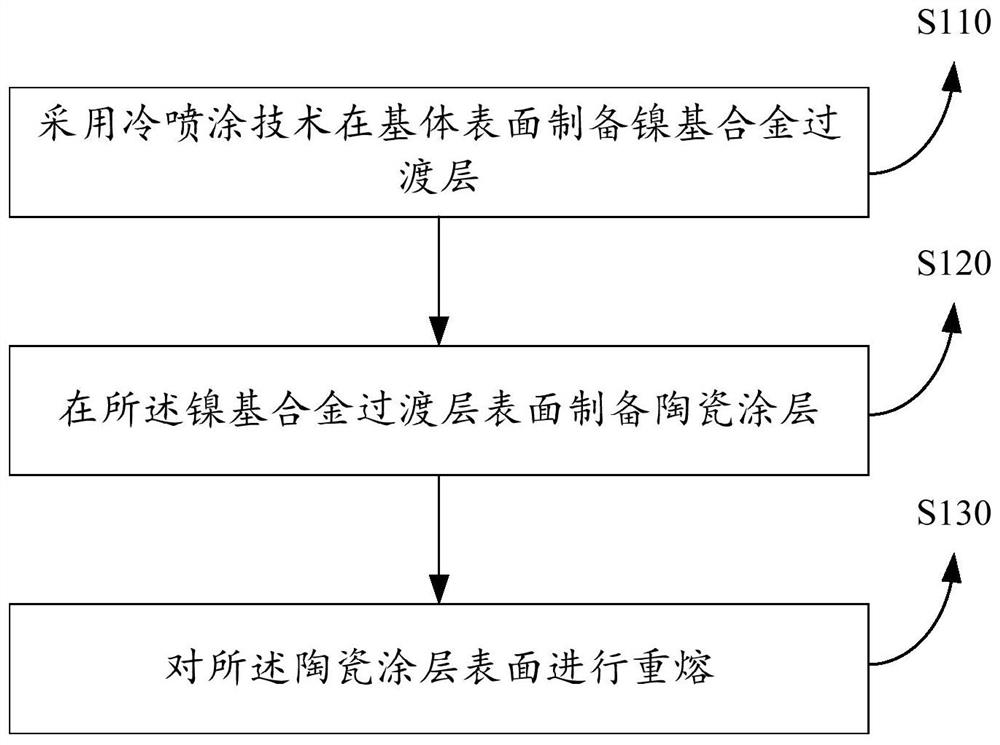

Preparation method of high-temperature-resistant anti-corrosion ceramic coating

PendingCN113388830AHigh bonding strengthImprove bindingMolten spray coatingSuperimposed coating processCeramic coatingInternal stress

The invention provides a preparation method of a high-temperature-resistant anti-corrosion ceramic coating. A nickel-based alloy transition layer is prepared on the surface of a substrate through a cold spraying technology, the ceramic coating is prepared on the surface of the nickel-based alloy transition layer, and the surface of the ceramic coating is remelted. According to the preparation method of the high-temperature-resistant anti-corrosion ceramic coating provided by the invention, the nickel-based alloy transition layer is prepared on the surface of a steel substrate through cold spraying, and the problems that as a traditional thermal spraying technology is adopted for preparing the transition layer, tensile stress is left in the coating, cracks and stripping are caused due to the fact that the tensile stress is easily and continuously increased in the subsequent thermal spraying of the ceramic coating are solved, and the internal stress of the cold spraying coating is pressure stress, a part of tensile stress generated by heating can be offset, then the binding force between the transition layer and the ceramic coating is improved, the outer surface layer of the prepared high-temperature-resistant anti-corrosion ceramic coating is compact, the inner layer of the prepared high-temperature-resistant anti-corrosion ceramic coating is porous, and the binding strength between the ceramic coating and the transition layer and the binding strength between the transition layer and the substrate are high, the high-temperature-resistant and corrosion-resistant performance is excellent, and the service life is long.

Owner:JIHUA LAB

Formula of silicone rubber

InactiveCN107099144AQuality improvementGood high temperature and corrosion resistanceAlkaneStearic acid

The invention discloses a formula of silicone rubber, which comprises the following raw materials in parts by weight: 80-100 parts of silicone rubber, 60-80 parts of low-phenyl silicone rubber, 20-30 parts of polyorganometallosiloxane, 5-15 parts of alkoxyl terminated polysiloxane, 10-15 parts of carbon black, 10-15 parts of graphite, 4-8 parts of vinyl silicone oil, 6-12 parts of zinc oxide, 1-6 parts of stearic acid, 2-4 parts of alkane oil, 1-3 parts of vulcanizing agent DBPH50, 1-1.5 parts of methyl ethyl silicon oil, 0.5-1.5 parts of hydroxyl silicone oil and 0.5-1.5 parts of hydrogen-containing silicone oil. The formula of the silicone rubber has good high-temperature resistance and corrosion resistance; the tear resistance can be greatly improved; and the quality of the silicone rubber is comprehensively improved.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

Foamed concrete and production process thereof

InactiveCN107500691AShort setting timeShorten the setting timeCeramicwareAluminium sulfateFoam concrete

The invention provides foamed concrete and a production process thereof. The foamed concrete is prepared from, by weight, 95-98% of aluminum sulfate cement, 0.05-0.2% of sodium metaaluminate, 0.05-0.2% of aluminum sulfate and 2-5% of hydrogen peroxide. The production process of the foamed concrete includes steps: 1, raw material preparation; 2, stirring and mixing; 3, adding hydrogen peroxide into a stirrer, and continuing mixing and stirring; 4, performing foam forming; 5, demoulding. The aluminum sulfate cement is used as a main material, a foaming agent, an accelerator and a set control agent are added, and then adding into a mould for foam forming is performed after well mixing. The foamed concrete has advantages of great thermal preservation effects, low cost and short set time, and accordingly foam concrete production efficiency can be effectively improved, and production cost is reduced.

Owner:DENGDIAN GROUP CEMENT

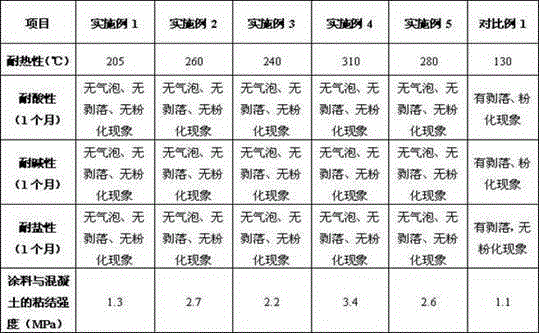

High-temperature-resistant and corrosion-resistant waterproof paint and preparation method thereof

InactiveCN105111883AImprove acid resistanceGood alkali resistanceAnti-corrosive paintsDicarbonateMaterials science

The invention discloses high-temperature-resistant and corrosion-resistant waterproof paint. The waterproof paint is prepared from, by weight, 40-65 parts of phenolic resin, 32-46 parts of methyl acrylate emulsion, 23-40 parts of methyl acrylate emulsion, 5-15 parts of n-Octyltrimethoxysilane, 6-18 parts of glycerin, 4-11 parts of calcium sulfate, 3-14 parts of aluminum chloride, 5-10 parts of aluminum oxide, 8-17 parts of talcum powder, 2-8 parts of sodium molybdate, 5-16 parts of short glass fibers, 2-10 parts of polyoxyethylene alcohol ether, 3-7 parts of isophorone diamine, 1-6 parts of diallyl 2,2'-oxydiethyl dicarbonate and 15-30 parts of deionized water. The invention further discloses a preparation method of the high-temperature-resistant and corrosion-resistant waterproof paint. The acid resistance, alkali resistance and salt corrosion resistance of the prepared waterproof paint are good, and the heat-resistance temperature ranges from 205 DEG C to 310 DEG C. The prepared waterproof paint has excellent high temperature resistance and corrosion resistance, and the application range of the waterproof paint can be expanded.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

High-strength wear-resistant alloy brush wire and production technology thereof

InactiveCN105949563AHigh strengthGood high temperature and corrosion resistanceWear resistantPolybutylene terephthalate

The invention discloses a high-strength wear-resistant alloy brush wire. The alloy brush wire comprises raw materials in percentage by mass as follows: 12%-20% of Cr, 8%-10% of Mn, 1.8%-3.2% of Mo, 6%-9% of Co, 2%-4% of Fe, 0.2%-0.8% of Ti, 0.6%-1.2% of Al, 0.05%-0.1% of C, 40%-55% of PE (polyethylene) resin, 30%-35% of PBT (polybutylene terephthalate) resin, 2%-5% of aminopropyltriethoxysilane, 2%-5% of aminopropyltrimethoxysilane, 0.05%-1% of an anti-wear agent, 0.05%-1% of an anti-aging agent, 1%-2% of a temperature resisting agent, 0.05%-1% of a plasticizer, 0.05%-1% of acetone and 10%-15% of diamond. The high-strength wear-resistant alloy brush wire has the advantages of better high-temperature wear resistance, better high-temperature corrosion resistance, better oxidation resistance, higher strength and the like, the service life of the alloy brush wire can be prolonged effectively, the reliability of the alloy brush wire can be improved effectively, a production technology of the alloy brush wire is controllable, the batch production can be realized.

Owner:QIANSHAN FUDA RUBBER BRUSH IND PROD FACTORY

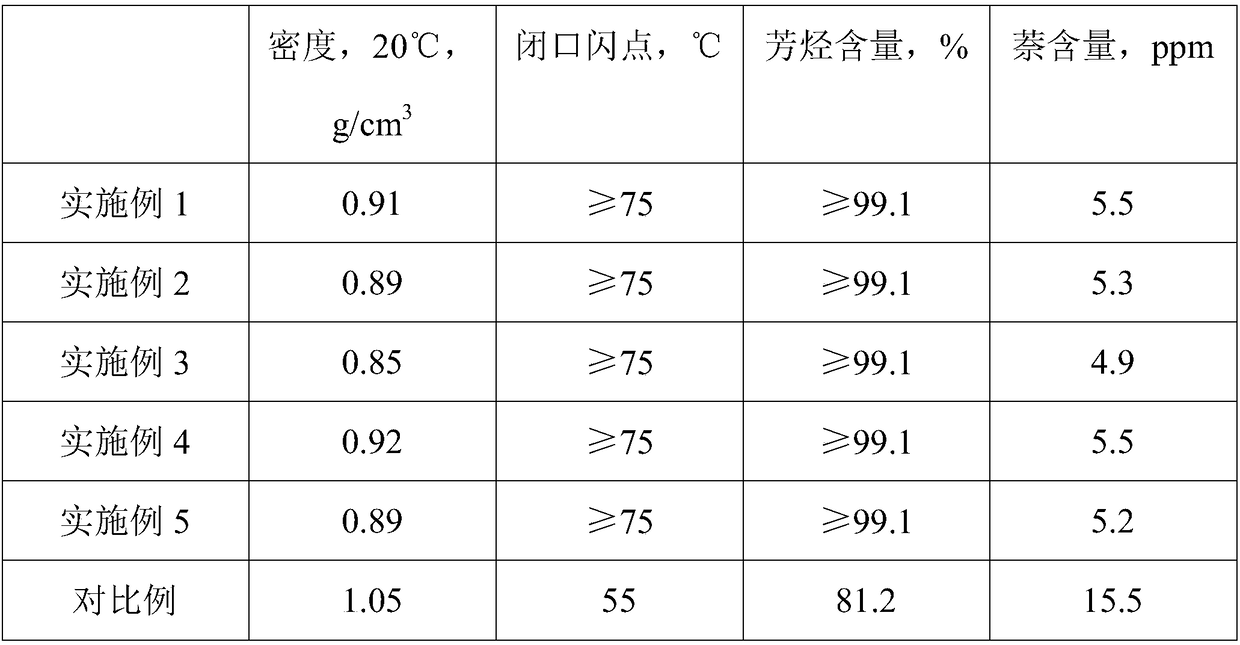

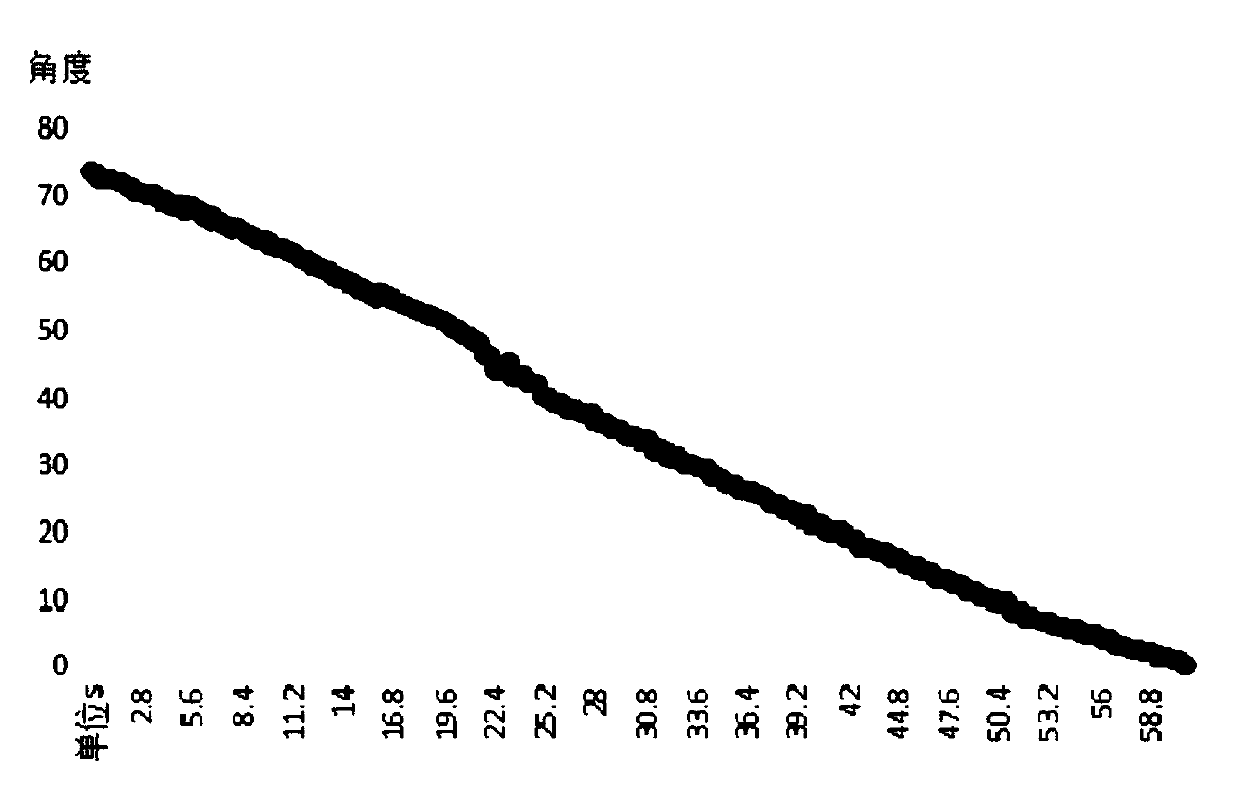

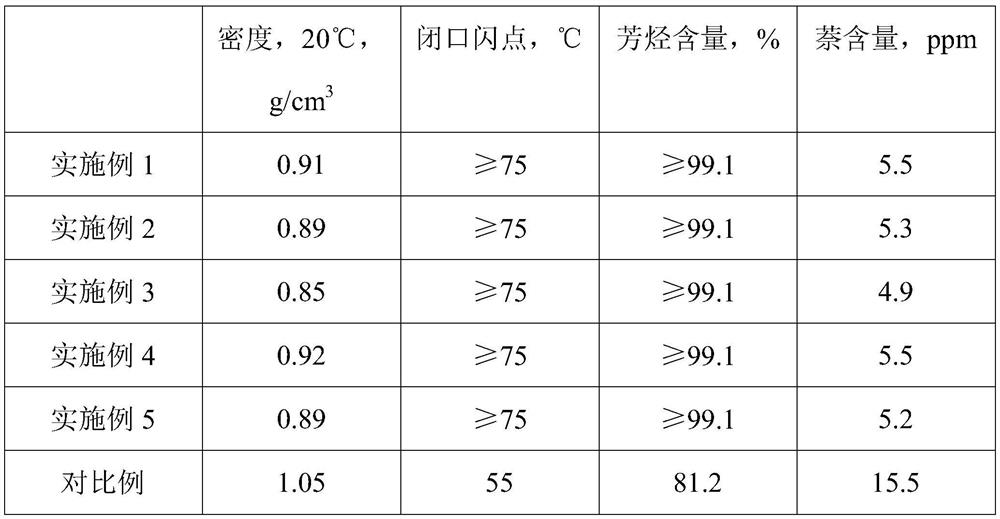

Preparation method of low naphthalene high-boiling-point aromatic solvent for rubber resin plasticizer

ActiveCN109337714AHigh yieldLow in naphthalenePhysical/chemical process catalystsTreatment with hydrotreatment processesRefluxAromatic solvent

The invention discloses a preparation method of a low naphthalene high-boiling-point aromatic solvent for a rubber resin plasticizer. The preparation method of the low naphthalene high-boiling-point aromatic solvent for the rubber resin plasticizer comprises the following steps: firstly, preparing a supported hydrogenation catalyst and a naphthalene remover; secondly, using cracked C10 fraction asa raw material to carry out hydrogenation and naphthalene removing treatment in sequence; and thirdly, adding the cracked C10 fraction to a rectifying tower; opening a vacuum system of the rectifyingtower; adjusting the vacuum degree of the vacuum system at -0.09 MPa; starting a reboiler heat conduction oil heating system of the rectifying tower; controlling the tower top temperature at 165.5 DEG C and the tower bottom temperature at 269.2 DEG C to carry out rectification under vacuum; condensing a vapor phase of the rectifying process by using a tower top condenser of the rectifying tower;enabling a condensate to enter a reflux drum; condensing and trapping non-condensed vapor phase by using a tower top condensing trap of the rectifying tower; enabling the trapped condensate to enter the reflux drum; controlling reflux amount; and collecting a fraction with temperature of 260-280 DEG C to prepare a target product. The preparation method of the low naphthalene high-boiling-point aromatic solvent for the rubber resin plasticizer, disclosed by the invention, has the advantages of simple operation, low cost, low naphthalene content of the prepared aromatic solvent, no toxicity andenvironmental protection.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

Graphene-based high-temperature-resistant anticorrosive paint and preparation method thereof

ActiveCN111057438AImprove high temperature and corrosion resistanceHigh elongation at breakFireproof paintsAnti-corrosive paintsBlack ferric oxideOrganosilicon

The invention relates to a graphene-based high-temperature-resistant anticorrosive paint and a preparation method thereof, and belongs to the technical field of anticorrosive materials, wherein the graphene-based high-temperature-resistant anticorrosive paint is obtained by mixing a component A and a component B according to a mass ratio of 9:1; the component A comprises the components in percentage by mass: 50 to 70% of a binding agent and 30 to 50% of a pigment filler; the binding agent comprises the components in percentage by mass: 60% of polymethylphenyl siloxane modified epoxy resin and40% of organic silicon; the pigment filler comprises the following components: graphene, chromium dioxide, titanium dioxide, zinc oxide, alumina powder, barium sulfate, magnesium carbonate, calcium carbonate, white carbon black micro-powder, quartz powder, graphite powder, green silicon carbide micro-powder, silicon carbide micro-powder, corundum micro-powder, silica powder, organic bentonite, mica powder and the balance being copper chromite black, iron oxide black and carbon fibers; and the component B is a curing agent. The anticorrosive paint has good comprehensive performance, strong corrosion resistance and high temperature resistance, and good comprehensive performance.

Owner:广东阿尔法工程材料有限公司

High-temperature-resistant corrosion-resistant coating material and preparation method of coating based on the coating material

InactiveCN103788809AExtended service lifeSimple ingredientsAnti-corrosive paintsPhenolic aldehydeMetal

The invention provides a high-temperature-resistant corrosion-resistant coating material. The coating material comprises, based on the total weight of each component in the coating material, 70-92 wt% of liquid phenolic resin and 8-30 wt% of porous silicon dioxide. In the liquid phenolic resin, the content of phenolic resin is 40-60 wt% and the phenolic aldehyde carbon residue rate is 40-65 wt%. The coating material is simple in component and low in cost. A coating obtained by processing can protect metal equipment operated in conditions of high temperature, high chlorine content and high acidity. The technology of the preparation method of the high-temperature-resistant corrosion-resistant coating is simple and easily achieved. The coating is sintered and carbonized in high temperature so that the coating has larger adhesive force and better high-temperature resistance and corrosion resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

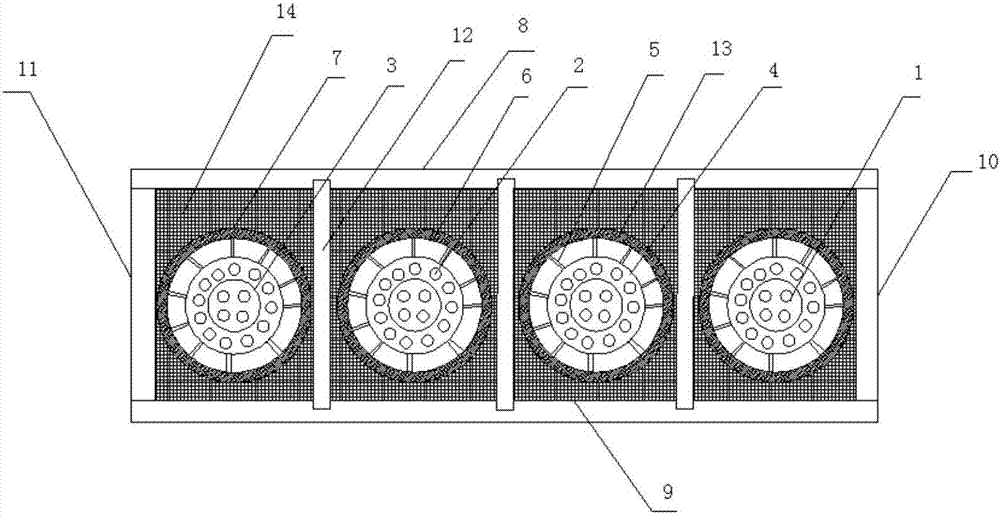

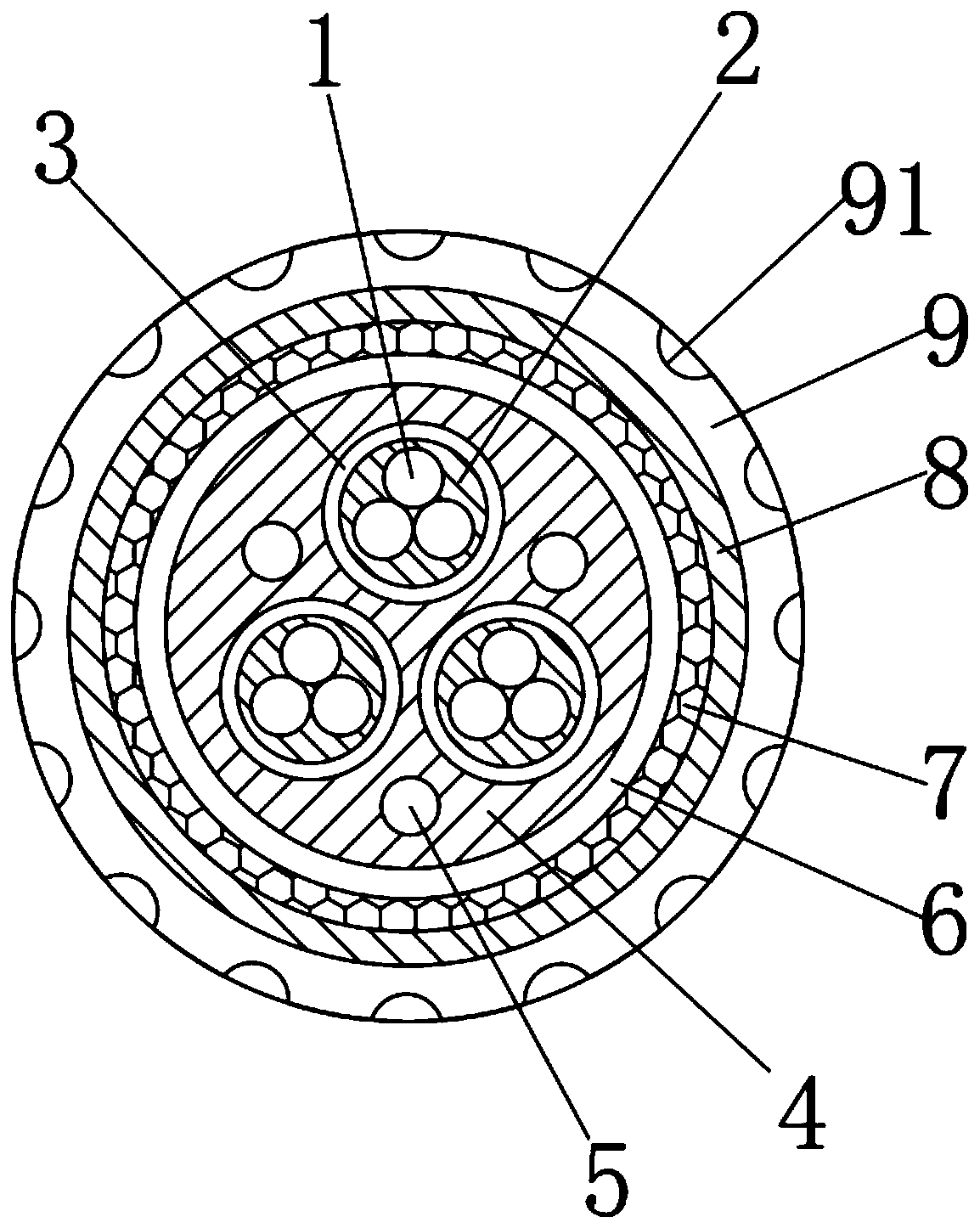

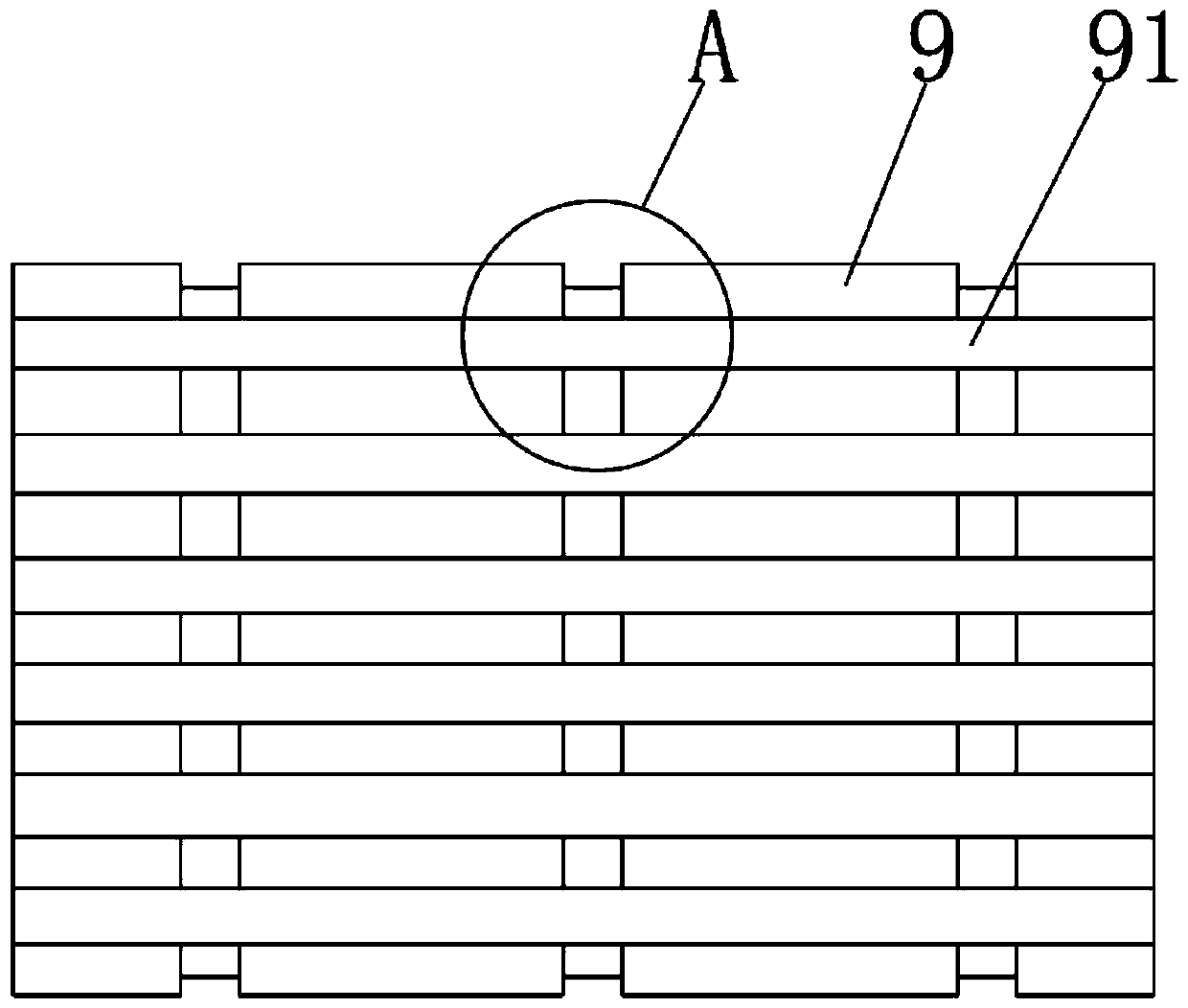

Moistureproof and flame-retardant insulated cable for instruments

InactiveCN108034123AImprove insulation performanceImprove defectsInsulated cablesInsulated conductorsEpoxyColemanite

The invention discloses a moistureproof and flame-retardant insulated cable for instruments. The cable comprises a conductor and a sleeve tube; an insulating layer is arranged outside the conductor, and the conductor and the insulating layer which is arranged outside the conductor are arranged in the sleeve tube; a gap is provided between the sleeve tube and the insulating layer, and the gap is fully filled with an epoxy resin foaming material; the sleeve tube comprises the following components in parts by mass: 40-50 parts of EVA resin, 20-25 parts of terpolymer EP rubber, 15-25 parts of an ethylene-vinyl alcohol copolymer, 15-20 parts of colemanite, 5-7 parts of polyacrylamide, 3-4 parts of norbornane diisocyanate, 5-10 parts of calcium carbonate, 8-12 parts of glass fibre, 6-10 parts ofdecabromodiphenyl ethane, 10-15 parts of polyvinylidene fluoride, 3-7 parts of sodium dodecyl sulfate, 10-13 parts of diatomite, 1-3 parts of chlorinated paraffin, 3-8 parts of crosslinked polyvinylpyrrolidone, 5-10 parts of a fire retardant, 3-5 parts of a curing agent, 2-3 parts of a silane coupling agent, and a proper amount of deionized water. The product has good moisture prevention and flame retardation effects.

Owner:SUZHOU HAOYAN PRECISION MOLD CO LTD

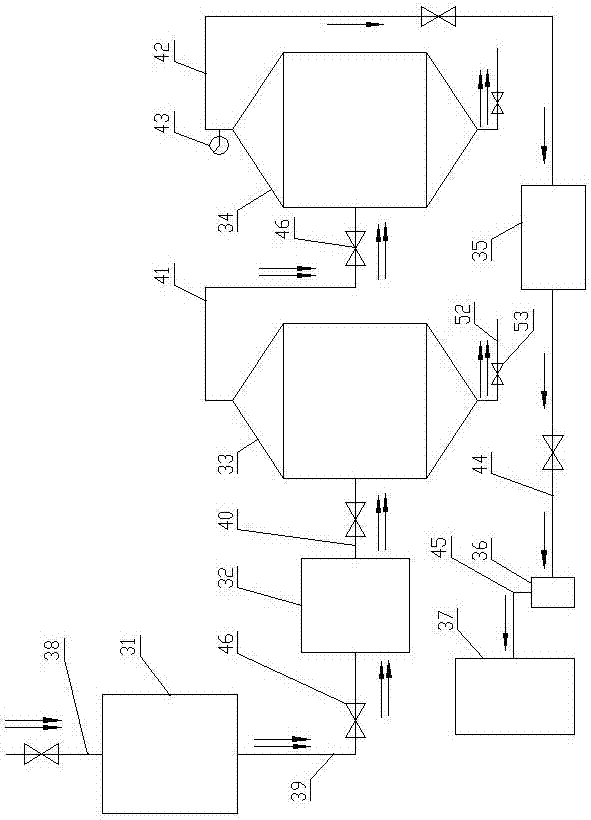

Biomass boiler smoke recycling system

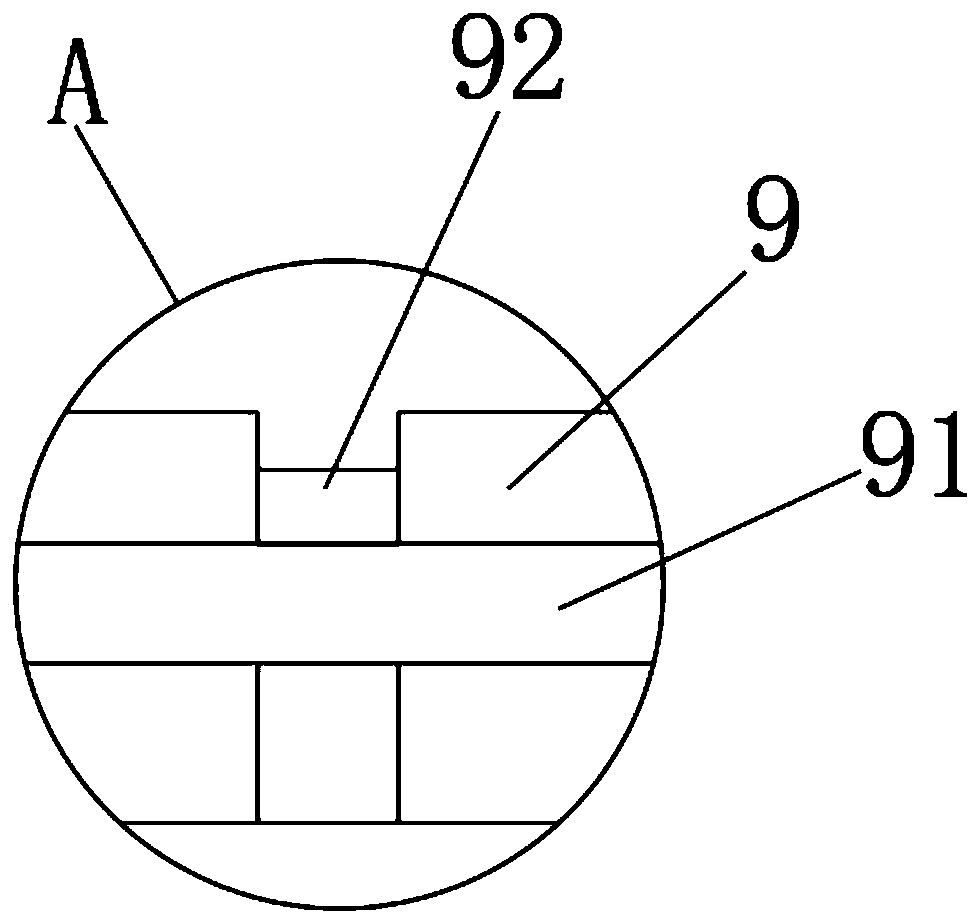

InactiveCN107166426AEasy to separateStable and durable preloadCombustion processIndirect carbon-dioxide mitigationAir preheaterSulfur

The invention discloses a biomass boiler smoke recycling system comprising an air preheater, a spray-type dust and sulfur removal device, a first-stage smoke plenum chamber, a second-stage smoke plenum chamber, a gas dryer, an air compressor and a high-pressure air storage tank which are sequentially connected by pipelines; and each of the pipelines is provided with a manual regulating valve with the same structure. The biomass boiler smoke recycling system is reasonable in design; the energy of smoke is sufficiently utilized, the smoke is subjected to environment-friendly treatment, and carbon monoxide gas generated by incomplete combustion is separated and reutilized, so that the favorable energy-saving and emission reduction effects are achieved; and the manual regulating valves are good in high temperature and corrosion resistance, capable of achieving a favorable sealing effect and easily regulating the sealing performance and are convenient to maintain and replace.

Owner:秦硕

High-strength anti-corrosive bus

PendingCN107394722AImprove current carrying capacityAvoid entanglementNon-macromolecular adhesive additivesTotally enclosed bus-bar installationsElectrical conductorHigh intensity

The invention discloses a high-strength anti-corrosive bus. The high-strength anti-corrosive bus comprises a bus body and a bus slot, wherein the bus body is arranged in the bus slot, the bus body is composed of a first conductive layer conductor and a second conductive layer conductor; the second conductive layer conductor surrounds the outer end of the first conductive layer conductor, and a high polymer material film is arranged between the second conductive layer conductor and the first conductive layer conductor; an insulating sleeve is arranged at the outside of the second conductive layer conductor, a pressure-sensitive adhesive tape is arranged on the outside surface of the insulating sleeve in a surrounding way, a shielding shell is arranged at the outside of the insulating sleeve, and a plurality of support members are uniformly arranged between the insulating sleeve and the shielding layer. The high-strength anti-corrosive bus disclosed by the invention is simple in structure, good in radiating effect, good in strength and corrosion resistance.

Owner:JIANGSU SHENFEI ELECTRICAL TECH CO LTD

Corrosion-resistant and high-temperature-resistant cable

InactiveCN111540524ANo obvious damageGood high temperature and corrosion resistanceInsulated cablesPower cablesFiberCarbon fibers

The invention discloses a corrosion-resistant and high-temperature-resistant cable including a wire core, the cable is characterized in that the outer side of the wire core is coated with a core-spunlayer, the outer side of the core-spun layer is coated with a rubber inner layer; the outer side of the rubber inner layer is coated with a waterproof layer; carbon fiber wires are inserted into the waterproof layer in a penetrating mode, the outer side of the waterproof layer is coated with a rubber middle layer, the outer side of the rubber middle layer is coated with a woven mesh layer, the outer side of the woven mesh layer is bonded with a tackifying layer, the outer side of the tackifying layer is coated with a rubber outer layer, and transverse grooves and radial grooves are formed in the outer side of the rubber outer layer. The corrosion-resistant and high-temperature-resistant cable has the advantages of high temperature resistance, corrosion resistance and good stripping resistance.

Owner:CHONGQING EASTFUL ELECTRIC WIRE & CABLE CO LTD

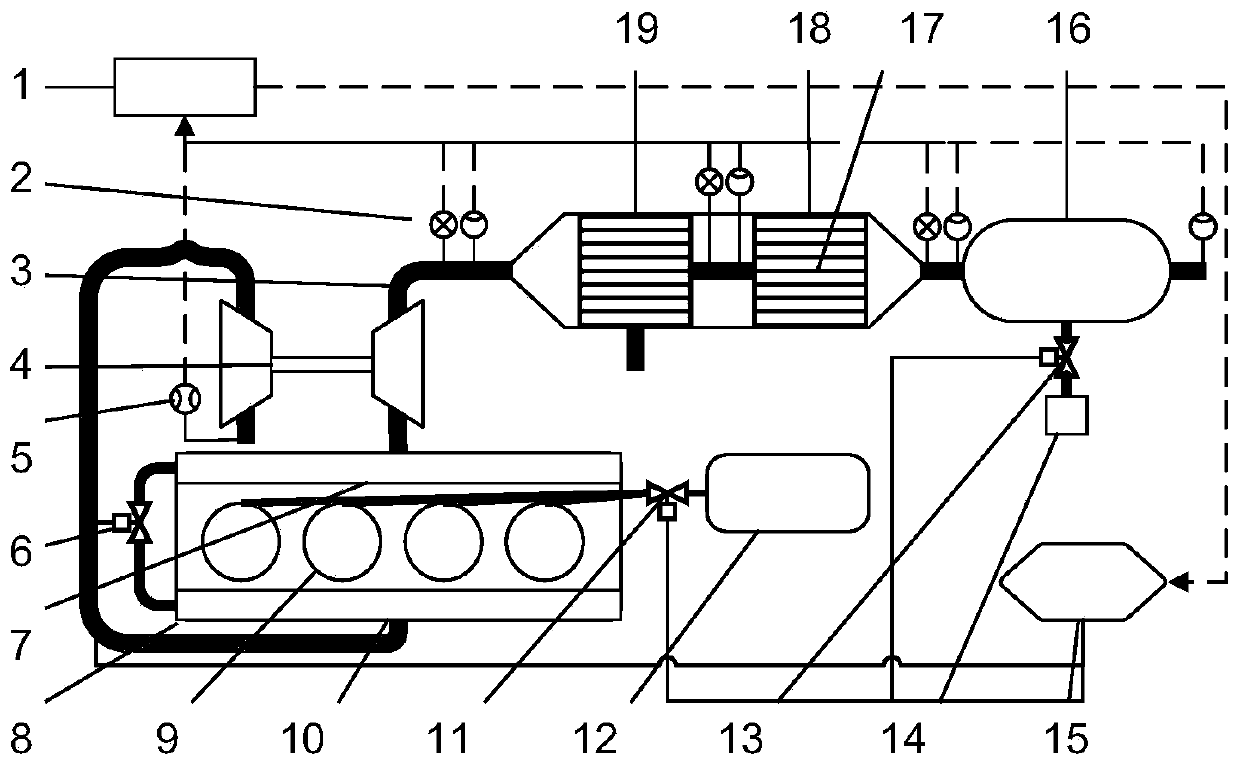

Diesel engine exhaust aftertreatment system based on high-chromium stainless steel and treatment method

InactiveCN109707495ALow costExtend your lifeElectrical controlInternal combustion piston enginesParticulatesData acquisition

The invention discloses a diesel vehicle China VI continuous regenerative filter and selective catalytic reduction combined system based on high temperature and corrosion resistant high-chromium stainless steel. The system comprises a diesel oxidation catalyst (DOC), a diesel particulate matter filter (DPF) and a selective catalytic reduction system (SCR) which are arranged on an exhaust pipe, temperature sensors, pressure sensors, flow sensors, a data acquisition module and a control unit. PM and NOx in exhaust are controlled through cooperative EGR valve control and internal combustion control of a fuel supply system. A filter material of the DPF adopts metal fiber braided fabric; and the high temperature and corrosion resistant high-chromium stainless steel can stand in a high-temperature and strong-corrosion atmosphere for a long time due to the low expansion coefficient of the stainless steel, compression and tensile stress produced due to radial and axial temperature gradients ofthe DPF can be effectively reduced, and the situation that deformation of the DPF causes cracks and cracking, and consequentially, the PM filter efficiency is dropped sharply is avoided.

Owner:ZHEJIANG UNIV

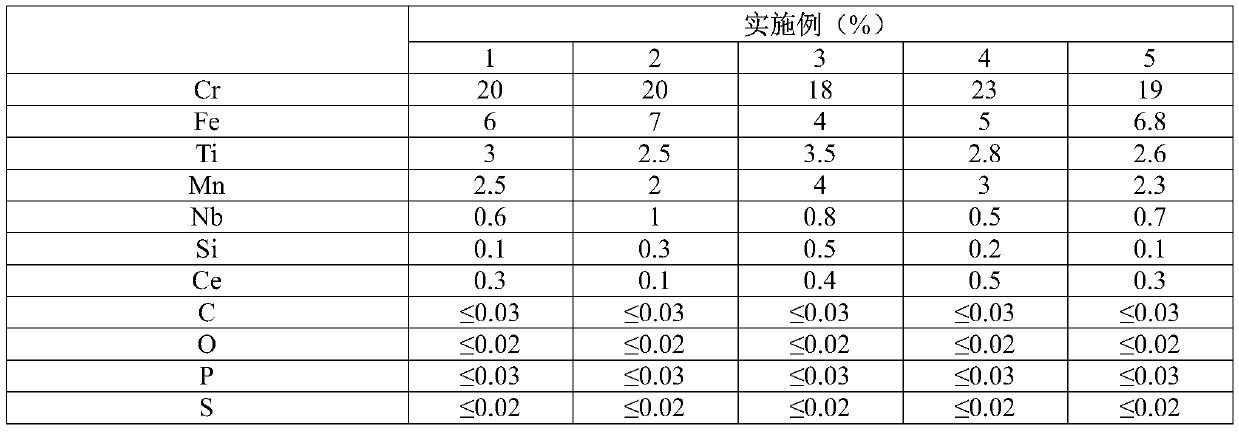

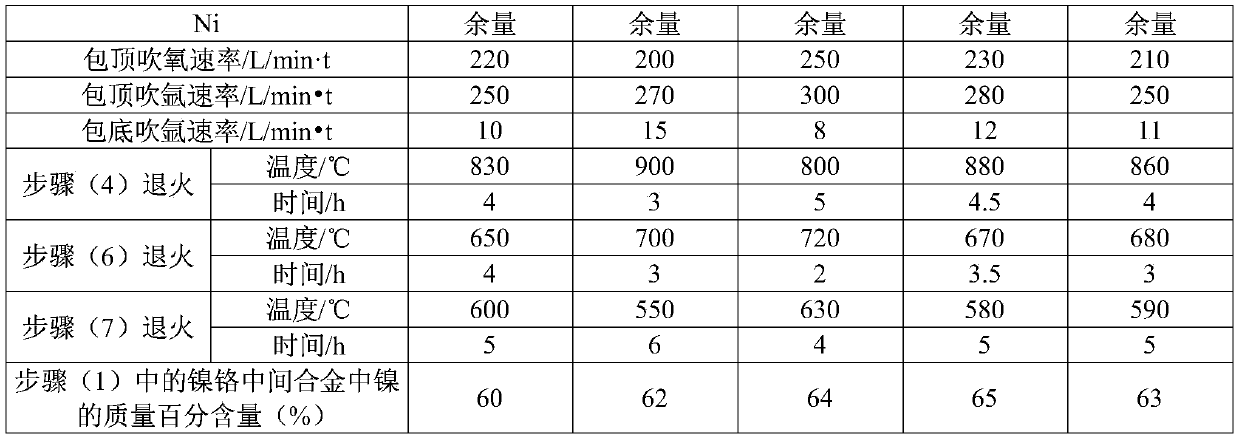

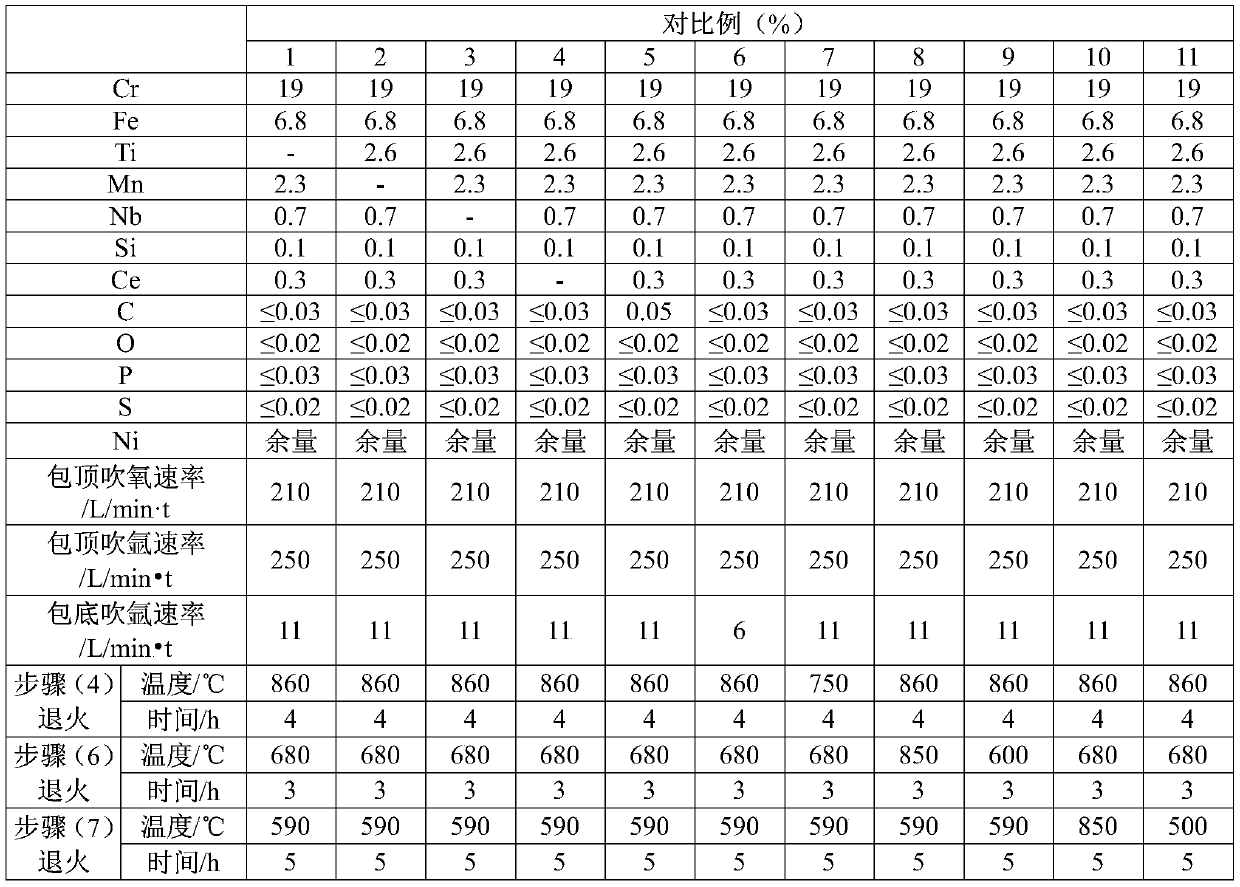

Preparation method of nickle-based high temperature and corrosion resistant welding wire

InactiveCN110014248AEvenly dispersedImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconOxygen

The invention belongs to the field of welding material and particularly relates to a preparation method of a nickle-based high temperature and corrosion resistant welding wire. The preparation methodcomprises the following steps: 1, preparing the raw materials according to the proportion, wherein chromium and partial nickle are prepared in the form of nickel-chromium intermediate alloy, adding other raw materials except titanium, chromium and partial nickle into a vacuum induction furnace, carrying out bottom argon blowing, and after the raw materials are completely melted, starting to carryout top blowing oxygen; 2, adding the nickel-chromium intermediate alloy 5-10 minutes after top blowing oxygen to melt and disperse the nickel-chromium intermediate alloy, stops blowing oxygen when the carbon content is reduced to less than 0.03%, and carrying out top blowing argon and bottom blowing argon simultaneously; 3, keeping bottom blowing argon, adding ferrosilicon and aluminium block insteel ladle for deoxidation, and then adding lime and fluorite for slagging and desulfuration; 4, casting melted liquid into alloy ingot, and annealing the alloy ingot; 5, forging the annealed alloy ingot at 1100-1200 DEG C into alloy billets, and rolling the alloy billets into wire rods; 6, carrying out acid pickling and coping to remove oxide skins and corrosion substance on the surfaces of thewire rods, annealing the wire rods, and drawing the wire rods into a welding wire; and annealing the welding wire.

Owner:DANYANG HUALONG SUPERIOR STEEL

Hard alloy material

ActiveCN106957981AGood high temperature and corrosion resistanceHigh hardnessBoron carbideTitanium nitride

The invention discloses a hard alloy material which comprises the following raw materials in parts by weight: 10-15 parts of titanium carbide, 4-7 parts of titanium nitride, 3-5 parts of tantalum carbide, 2-4 parts of boron carbide, 25-35 parts of SiC-Al2O3-Y2O3 nano composite powder, 15-20 parts of nickle-base carbon tungsten alloy powder and 5-8 parts of a metal binder. The hard alloy material has excellent high-temperature resistance and corrosion resistance; and compared with the traditional steel material, the hard alloy material has excellent hardness, heat resistance and oxidation resistance and can improve the high-temperature resistance, toughness and the like of an alloy tool.

Owner:株洲湘钨超硬材料有限公司

A process gas chromatograph

ActiveCN105424852BSimple structureVersatilityComponent separationResponse sensitivityChromatographic separation

The invention relates to a process gas chromatograph. The process gas chromatograph comprises an alloy substrate, a master controller, a chromatographic detection module, an automatic sampler, a flow distribution module, a chromatographic separation module, a data acquisition module, a time control module, a power module, a gas impurity detection device, a gas leakage detection device, an alarm device, an automatic stop module and a protection shell. The process gas chromatograph can complete multi-path gas phase detection automatically; besides, the process gas chromatograph has good high temperature resistance and corrosion resistance and can be reliably used for a long time; furthermore, result errors caused when impurities are mixed into gas samples can be completely eliminated, further losses of production and study can be avoided, and gas leakage can be found in time once happening; the process gas chromatograph is simple in structure, wide in measurement range and high in response speed and has universality and response sensitivity to many substances, and response signals are stable.

Owner:HARBIN YULONG AUTOMATION

Preparation method of high-temperature direct-injection dispersed water-based ink

The invention discloses a preparation method of high-temperature direct-injection dispersed water-based ink, and the method comprises the following steps: mixing modified water-based acrylic resin with an antibacterial agent to obtain a solution A; sequentially adding deionized water, ethyl alcohol and a modified dispersing agent into the solution A to be mixed for 1-2 h, and obtaining a solution B; adding a water-based organic pigment into the solution B, adding a defoaming agent, and grinding through a three-roller grinder to obtain a solution C; sequentially adding deionized water, ethyl alcohol, water-based wax emulsion and a water-based flatting agent into the solution C, performing stirring and mixing at the rotating speed of 2,000 r / min, adding organic amine to adjust the pH to be 8-9, performing grinding through a three-roller grinding machine, and obtaining the water-based ink. The water-based ink has good stability, high temperature resistance and corrosion resistance, and due to the addition of the antibacterial agent, the water-based ink has good antibacterial performance; meanwhile, the water-based organic pigment and the auxiliaries can be uniformly dispersed through the modified dispersing agent.

Owner:深圳市凌普鑫科技有限公司

Preparation method for absorbent for smoke decarburization

InactiveCN107376593AGood dispersionStable structureGas treatmentDispersed particle separationBoron nitrideMuffle furnace

The invention discloses a preparation method for an absorbent for smoke decarburization. The preparation method comprises the following steps: using a boron nitride nano-sheet / montmorillonoid intercalation composite material, preparing a polysiloxane crosslinking compound on the surface of the composite material, and uniformly mixing with fluorite powder, calcium carbonate, sodium silicate and silicon nitride, die-filling, degassing, and compression-forming, drying an obtained rough body and placing in a muffle furnace for sintering, to obtain a porous carrier; adding ethyl succinate to diethyl carbonate, stirring and uniformly mixing, to obtain mixed solution B; adding the prepared porous carrier to the mixed solution B, soaking for 15 h, centrifugally removing the unadsorbed mixed solution after soaking, and finally drying the porous carrier adsorbed with the mixed solution, to obtain the compound absorbent. The prepared absorbent by the method has the large absorptive capacity, and is capable of effectively removing carbon dioxide in the smoke.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

A kind of high permeability ultrafiltration composite ceramic coating membrane and preparation method thereof

ActiveCN107519772BHigh selectivityImprove permeabilityUltrafiltrationIn situ polymerizationUltrafiltration

The invention relates to a highly-permeable ultrafiltration composite ceramic coating film and a preparation method thereof, and belongs to the technical field of film separation. The highly-permeable ultrafiltration composite ceramic coating film comprises a ceramic base film, wherein the surface of the ceramic base film is sequentially provided with a silane coupling layer, a polyimide layer from interior to exterior; the mass ratio of the ceramic base film to the silane coupling layer to the polyimide layer is 1:(0.001 to 0.005):(0.01 to 0.1). The highly-permeable ultrafiltration composite ceramic coating film has the advantages that hyperbranched polyamide-amide is used as a pore passage building template, polyimide is used as a separating film, and the polyimide is grafted to the surface of the ceramic film in a covalent way by in-situ polymerizing, so that the composite separating film can simultaneously reach the high-selectivity and high-permeability advantages of a polymer film and high temperature-resistant and corrosion-resistant advantages of an inorganic film; the pore passage size and structure of the commercial ceramic film are improved, and the good permeability of the separating film is realized.

Owner:佛山市维宁新材料有限公司

Preparation method of low naphthalene high boiling point aromatic hydrocarbon solvent for rubber resin plasticizer

ActiveCN109337714BHigh yieldLow in naphthalenePhysical/chemical process catalystsTreatment with hydrotreatment processesCondensation trapPtru catalyst

The invention discloses a method for preparing a low-naphthalene and high-boiling-point aromatic hydrocarbon solvent used for rubber resin plasticizers, comprising the following steps: firstly preparing a loaded hydrogenation catalyst and a naphthalene-removing agent, and then using cracking C 10 The distillate is used as raw material, which is subjected to hydrogenation and denaphthalene treatment in sequence, and finally added to the rectification tower, and the vacuum system of the rectification tower is turned on, and the vacuum degree is adjusted to ‑0.09MPa; the reboiler of the rectification tower is started to be heated The system controls the tower top temperature at 165.5°C and the tower bottom temperature at 269.2°C, and performs vacuum rectification. The gas phase of the rectification process is condensed by the top condenser of the rectification tower, and the condensate enters the reflux tank, and the uncondensed gas phase undergoes rectification. The condensate trap at the top of the tower is condensed and collected, and the captured condensate enters the reflux tank, the reflux flow is controlled, and the fraction at 260‑280 ° C is collected to obtain the target product. The method is simple in operation, low in cost, low in naphthalene content in the prepared aromatic hydrocarbon solvent, non-toxic and environment-friendly.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

High-temperature high-pressure sampling valve used for deep sea

InactiveCN101464229BImprove sealingGood high temperature and corrosion resistanceWithdrawing sample devicesEngineeringHigh pressure

The invention discloses a high-temperature high-pressure sampling valve used in deep water. The sampling valve mainly comprises a valve body, a valve housing, a first valve core, a second valve core, a spring cavity and a return spring. The invention has the two-way self-fastening sealing capacity due to the adoption of the structural manner of two valve cores, so that the sampling valve has excellent sealing performance under a high pressure. The sampling valve has superior high-temperature resistance and decay resistance, thereby improving the fidelity of thermal water samples. The samplingvalve opens under linear driving, and closes automatically following the withdrawl of external driving force, thereby increasing the convenience of use in deep water.

Owner:ZHEJIANG UNIV

Brush wire with high corrosion resistance and high wear resistance and manufacturing method thereof

InactiveCN111719197AExtended service lifeImprove use reliabilityBristleConjugated synthetic polymer artificial filamentsPolyamideDioxyethylene Ether

The invention discloses a brush wire with the high corrosion resistance and the high wear resistance. The brush wire comprises, by mass percentage, 8%-10% of Cr, 1.8%-3.2% of Mo, 1%-2.0% of Mn, 1%-3%of Fe, 0.2%-1% of Ti, 0.4%-1.5% of Al, 0.05%-0.1% of C, 1%-1.5% of Si, 0.2%-1% of Ni, 10%-15% of diamonds, 30%-35% of polyamide resin, 20%-25% of PBT resin, 10%-15% of fatty alcohol polyoxyethylene ether, 2%-5% of aminopropyl trimethylamino silane, 0.05%-1% of anti-wear agent, 0.05%-1% of lubricating agent, 0.05%-1% of temperature resisting agent, 0.05%-1% of plasticizer, 0.05%-1% of anti-aging agent, 0.05%-1% of antioxidant, 0.05%-1% of curing agent and 0.05%-1% of accelerant. Compared with the prior art, the brush wire has the advantages of being high in high temperature wear resistance, high in high temperature corrosion resistance, high in oxidation resistance, high in strength and the like, the service life of an engine brush seal can be effectively prolonged, the reliability of the engine brush seal can be effectively improved, a production technology of the brush wire is controllable, and batch production can be conducted.

Owner:安徽盛世旺达刷业有限公司

Preparation method of positively charged ceramic micro-nano fiber membrane

InactiveCN103451850BHigh porosityLarge specific surface areaHeating/cooling textile fabricsNon-woven fabricsPorosityMicro nano

The invention discloses a preparation method of a positively-charged ceramic micro-nano fiber membrane. The preparation method comprises the steps of adding spinnable polymer in a solvent, then adding a ceramic precursor in the solvent, and obtaining spinning solution after stirring and aging; pouring the spinning solution in a micro pump, adopting an injection needle head which is scraped smoothly as a spray nozzle, and obtaining composite fiber through electrostatic spinning; firstly roasting the composite fiber in anoxic atmosphere at 200-500 DEG C, then roasting the composite fiber in inertia or reducing atmosphere at 400-400 DEG C for 1-5 hours, and obtaining the positively-charged ceramic micro-nano fiber membrane. According to the preparation method of the positively-charged ceramic micro-nano fiber membrane, disclosed by the invention, the positively-charged ceramic micro-nano fiber membrane which is prepared by combining the electrostatic spinning and a step-by-step roasting technology has high porosity, high specific surface area, high surface electrical performance and good high-temperature-resisting and corrosion-resisting performances, has great advantages of separating, shielding and removing bacteria and virus and has a wide application prospect in environment cleaning, pharmaceuticals production, bioengineering, foundation medicine and the like.

Owner:XIAN UNIV OF TECH

Compression resistant foaming microcrystal glass plate and preparation method thereof

The invention discloses a compression resistant foaming microcrystal glass plate and a preparation method thereof, relating to the technical field of glass products. The microcrystal glass plate contains the following materials: siderite, vein quartz, limestone, floating bead powder, flint clay, andalusite, cordierite, titanium tetrachloride, zirconium silicate, sodium carbonate and compound metaloxide. The preparation method comprises the steps of smashing and magnetic separation, pickling and drying, melting, molding, and annealing of a raw material. The microcrystal glass plate disclosed by the invention is simple in preparation, has excellent wear resistance and corrosion resistance, heat insulation and sound insulation property and mechanical performances, and is long in service lifeand wide in application.

Owner:合肥钢骨玻璃制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com