High-strength anti-corrosive bus

A corrosion-resistant, high-strength technology, applied in the direction of fully enclosed busbar devices, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve problems such as high contact resistance, insufficient strength, and unreliable connections. problem, to achieve the effect of reduced failure rate, good stability and improved anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

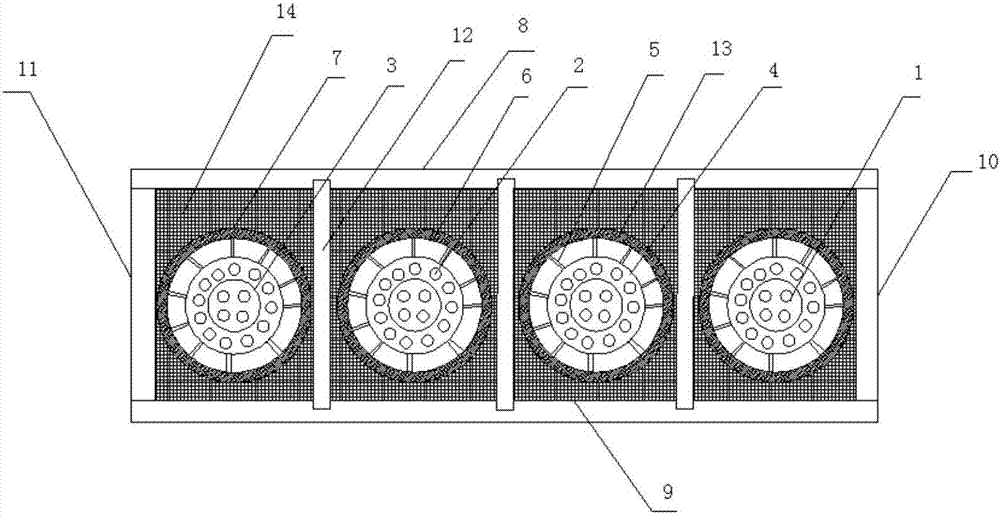

[0021] This embodiment provides a high-strength corrosion-resistant busbar, the structure of which is as follows figure 1 As shown, it includes the busbar body and the busway. The busbar body is composed of the first conductive layer conductor 1 and the second conductive layer conductor 2. The second conductive layer conductor 2 surrounds the outer end of the first conductive layer conductor 1, and the second conductive layer conductor A polymer material film 3 is arranged between the conductor 2 and the first conductive layer conductor 1, the polymer material film is polytetrafluoroethylene, an insulating sleeve 4 is arranged outside the second conductive layer conductor 2, and an insulating sleeve 4 is arranged outside the insulating sleeve 4. The surface is surrounded by a pressure-sensitive adhesive tape, and a shielding shell 6 is provided on the outside of the insulating sleeve 4, and several support members 5 are uniformly arranged between the insulating sleeve 4 and the...

Embodiment 2

[0029] This embodiment provides a high-strength corrosion-resistant busbar, the structure of which is as follows figure 1 As shown, it includes the busbar body and the busway. The busbar body is composed of the first conductive layer conductor 1 and the second conductive layer conductor 2. The second conductive layer conductor 2 surrounds the outer end of the first conductive layer conductor 1, and the second conductive layer conductor A polymer material film 3 is arranged between the conductor 2 and the first conductive layer conductor 1, the polymer material film is polytetrafluoroethylene, an insulating sleeve 4 is arranged outside the second conductive layer conductor 2, and an insulating sleeve 4 is arranged outside the insulating sleeve 4. The surface is surrounded by a pressure-sensitive adhesive tape, and a shielding shell 6 is provided on the outside of the insulating sleeve 4, and several support members 5 are uniformly arranged between the insulating sleeve 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com