High-temperature high-pressure sampling valve used for deep sea

A high temperature and high pressure, sampling valve technology, applied in the direction of sampling devices, etc., can solve the problems of increasing the complexity of sampling equipment, and the corrosion resistance cannot meet the requirements, and achieves increased convenience, good sealing performance, and excellent high temperature and corrosion resistance. Effect

Inactive Publication Date: 2011-01-05

ZHEJIANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the high-temperature valves commonly used are made of stainless steel, which cannot meet the requirements in terms of corrosion resistance.

Although the existing titanium alloy stop valve can be used for hydrothermal sampling, it needs to rotate the handle on the stop valve to open and close the valve, and a complicated driving mechanism is required on the sampling device to realize this action, which will increase the complexity of the sampling device degree

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

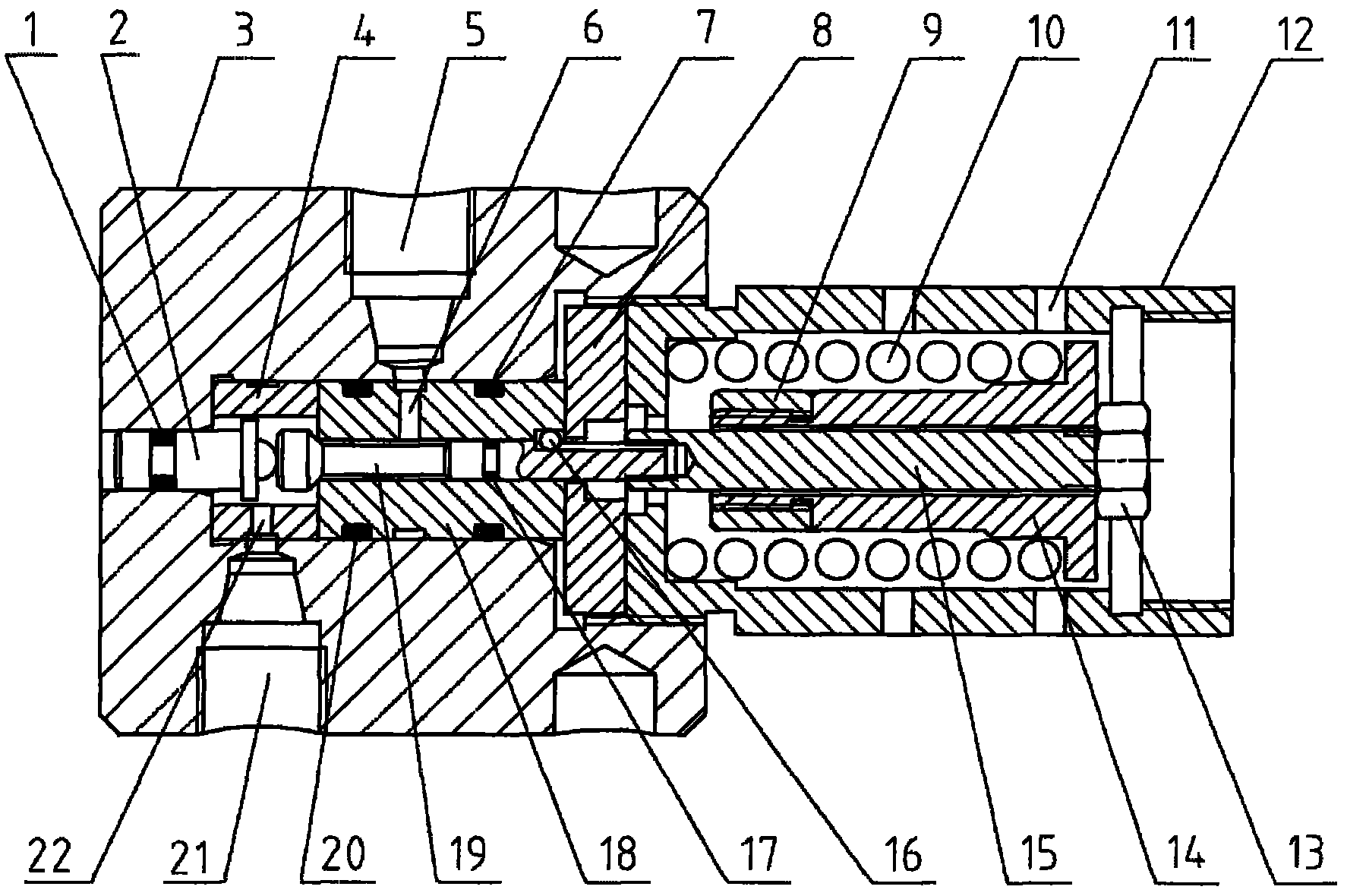

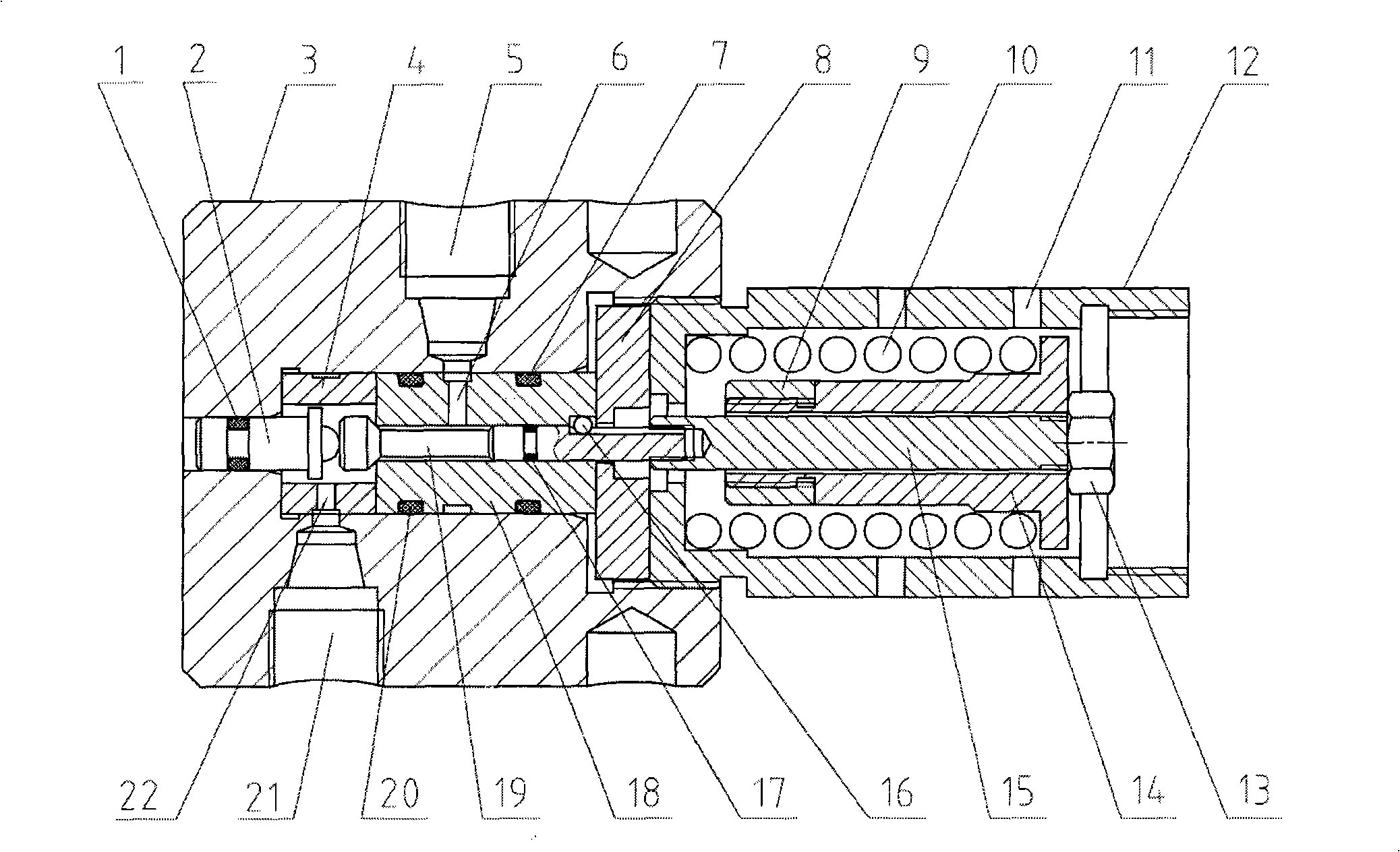

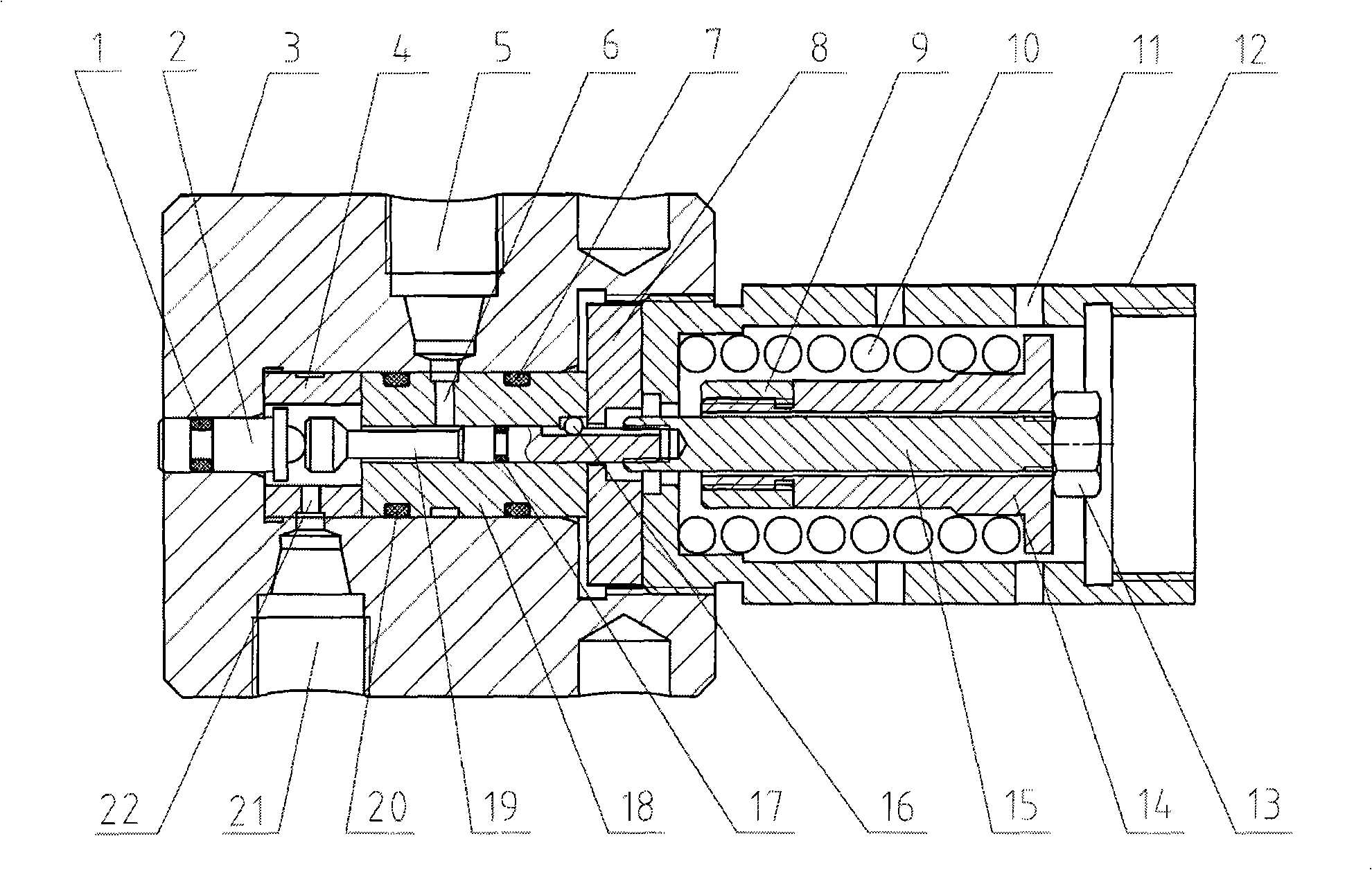

The invention discloses a high-temperature high-pressure sampling valve used in deep water. The sampling valve mainly comprises a valve body, a valve housing, a first valve core, a second valve core, a spring cavity and a return spring. The invention has the two-way self-fastening sealing capacity due to the adoption of the structural manner of two valve cores, so that the sampling valve has excellent sealing performance under a high pressure. The sampling valve has superior high-temperature resistance and decay resistance, thereby improving the fidelity of thermal water samples. The samplingvalve opens under linear driving, and closes automatically following the withdrawl of external driving force, thereby increasing the convenience of use in deep water.

Description

A high temperature and high pressure sampling valve for deep sea technical field The invention relates to a high-temperature and high-pressure sealing device, in particular to a high-temperature and corrosion-resistant deep-sea high-pressure sampling valve. Background technique Deep-sea hydrothermal vents are generally distributed on the seabed at a depth of 2,000 to 3,000 meters. The maximum temperature of the hydrothermal fluid can reach 400°C. Due to the high salinity and low pH value of the hydrothermal fluid, it is highly corrosive. The high temperature, high pressure and strong corrosive characteristics of hydrothermal fluids pose great challenges to the manufacture of suitable sampling equipment. In hydrothermal sampling equipment, the sampling valve is the most critical component for obtaining high-quality samples. It must not only have good sealing performance under high pressure, but also need high temperature resistance and corrosion resistance. Most of the com...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N1/10

Inventor 杨灿军吴世军丁抗谢延青杨磊陈鹰

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com