Preparation method of high-temperature-resistant anti-corrosion ceramic coating

A ceramic coating, high temperature resistant technology, applied in the surface field, can solve problems such as affecting the protective effect of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

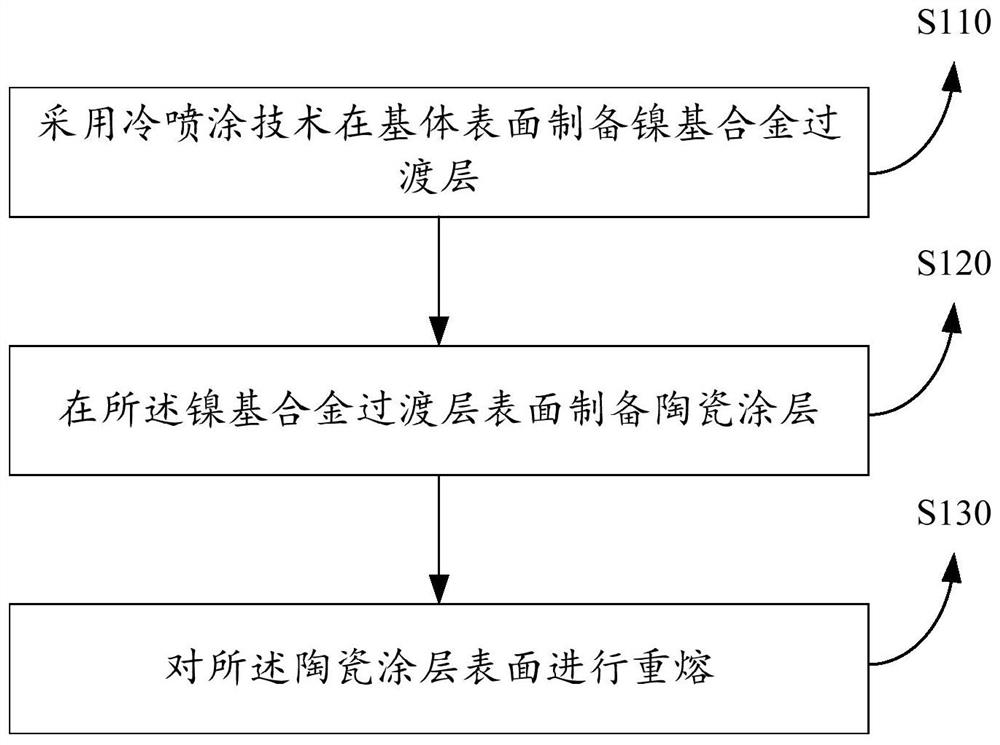

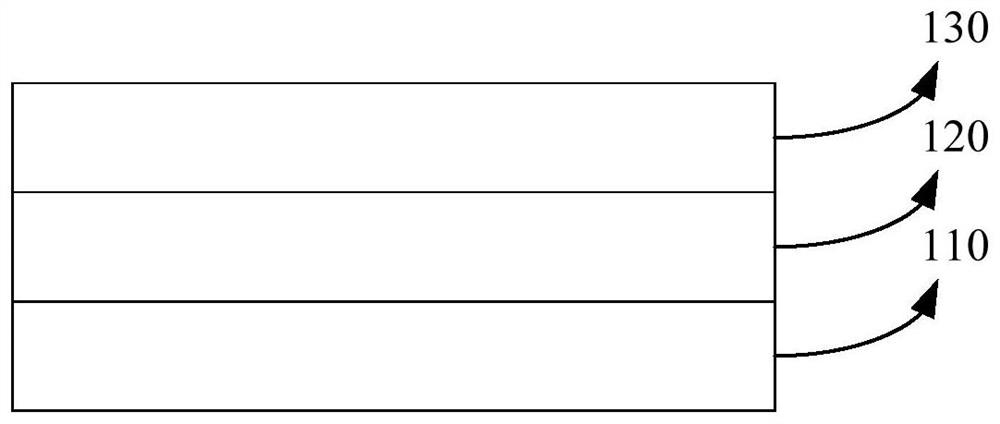

[0033] see figure 1 , a flow chart of the steps for the preparation method of the high-temperature-resistant and anti-corrosion ceramic coating provided by the application, comprising the following steps:

[0034] Step S110: Prepare a nickel-based alloy transition layer on the surface of the substrate by cold spraying technology.

[0035] In some of the embodiments, the main gas of the cold spraying is nitrogen or helium, the pressure is 2-3.5MPa, and the temperature is 300-600°C. The base is steel.

[0036] In some of the embodiments, the composition of the nickel-based alloy is NiCrAlY, the particle size is 15-45 μm, and the shape is spherical or nearly spherical.

[0037] In some of the embodiments, the nickel-based alloy transition layer has a thickness of 150-200 μm.

[0038] It can be understood that the present application adopts cold spraying technology to prepare the nickel-based alloy transition layer. Compared with the traditional thermal spraying transition laye...

Embodiment 1

[0056] The NiCrAlY transition layer was prepared on the surface of the steel substrate by cold spraying equipment. Among them, the main gas of cold spraying is nitrogen, the pressure is 3.5MPa, the temperature is 500°C, the particle size of NiCrAlY raw material powder is 15-45μm, the spraying distance is 30mm, and the spraying time is 2 minutes to form a transition layer with a thickness of 150μm.

[0057] Then PVA, PEG, deionized water and Al 2 o 3 Weighing and mixing, high-energy ball milling for 48 hours, and agglomerated ceramic powders were obtained by spray-drying technique. Wherein, the contents of PVA and PEG are both 1wt.%, the solid content of Al2O3 is 60wt.%, and the particle size of the agglomerated powder after spray drying is 50-75μm.

[0058] Then, a ceramic coating is prepared on the surface of the transition layer by using the plasma spraying technique and the agglomerated ceramic powder. Among them, the plasma spraying power is 40kW, the spraying distance ...

Embodiment 2

[0061] A NiAl alloy transition layer was prepared on the surface of the steel substrate by cold spraying equipment. Among them, the main gas of cold spraying is nitrogen, the pressure is 3.5MPa, the temperature is 400℃, the NiAl alloy raw material powder is Ni-coated Al powder, the particle size is 15-45μm, the spraying distance is 30mm, the spraying time is 2 minutes, and the forming thickness is 200μm transition layer.

[0062] Then PVA, PEG, deionized water and Al 2 o 3 Weighing and mixing, high-energy ball milling for 48 hours, and agglomerated ceramic powders were obtained by spray-drying technique. Among them, PVA and PEG content are 1.5wt.%, Al 2 o 3 The solid content is 60wt.%, and the particle size of the agglomerated powder after spray drying is 50-75 μm.

[0063] Then, a ceramic coating is prepared on the surface of the transition layer by using the plasma spraying technique and the agglomerated ceramic powder. Among them, the plasma spraying power is 45kW, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com