TiB2-Ni-based metal-ceramic composite feed for thermal spraying and preparation method of TiB2-Ni-based metal-ceramic composite feed

A technology of ceramic composite and composite structure, applied in metal processing equipment, metal material coating process, coating and other directions, to achieve the effects of excellent fluidity, improved bonding strength and toughness, and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

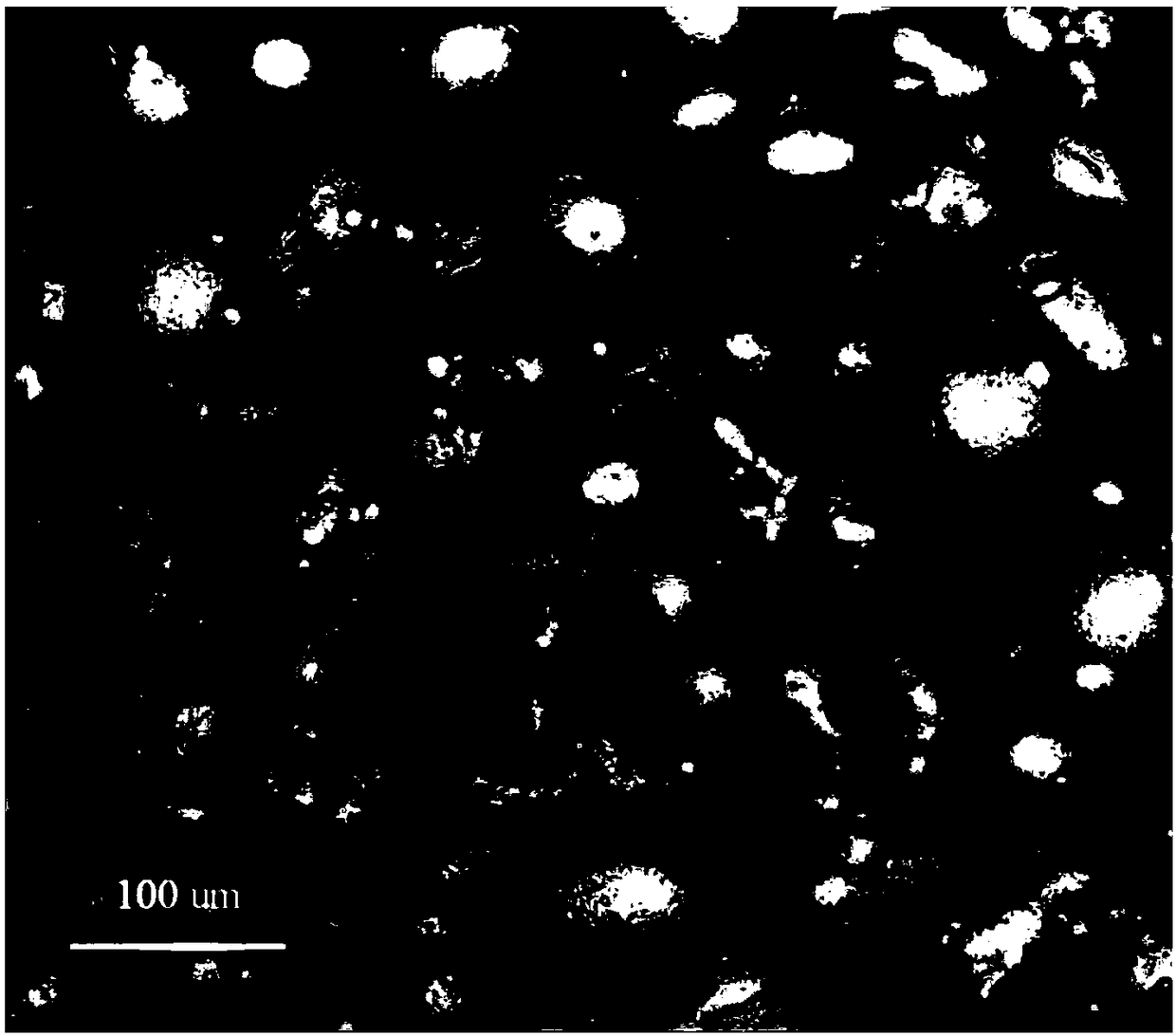

[0053] This embodiment provides a kind of TiB for thermal spraying 2 - Ni-based metal-ceramic composite structure feeding material and preparation method thereof, the metal-ceramic nano-composite structure feeding material is made of TiB 2 It is prepared by combining spray drying and plasma spheroidization technology with a volume ratio of 1:1 with Ni-based alloy.

[0054] A kind of TiB for thermal spraying 2 -The preparation method of Ni base cermet composite structure feeding material, comprises the steps:

[0055] (1) Under an argon protective atmosphere, add TiB with a volume ratio of 1:1 to the stirring mill 2 powder and Ni-based alloy powder, then add industrial alcohol of 2 / 3 of the volume of the mixing tank as a process control agent, and add polyethylene glycol as a binder, wherein polyethylene glycol and mixed powder (TiB 2 Powder and Ni-based alloy powder, the same below) with a mass ratio of 1:100, finally add zirconia balls as grinding media, and then grind for...

Embodiment 2

[0061] This embodiment provides a kind of TiB for thermal spraying 2 - Ni-based metal-ceramic composite structure feeding material and preparation method thereof, the metal-ceramic nano-composite structure feeding material is made of TiB 2 It is prepared by combining spray drying and plasma spheroidization technology with a volume ratio of 1:1 with Ni-based alloy.

[0062] A kind of TiB for thermal spraying 2 -The preparation method of Ni base cermet composite structure feeding material, comprises the steps:

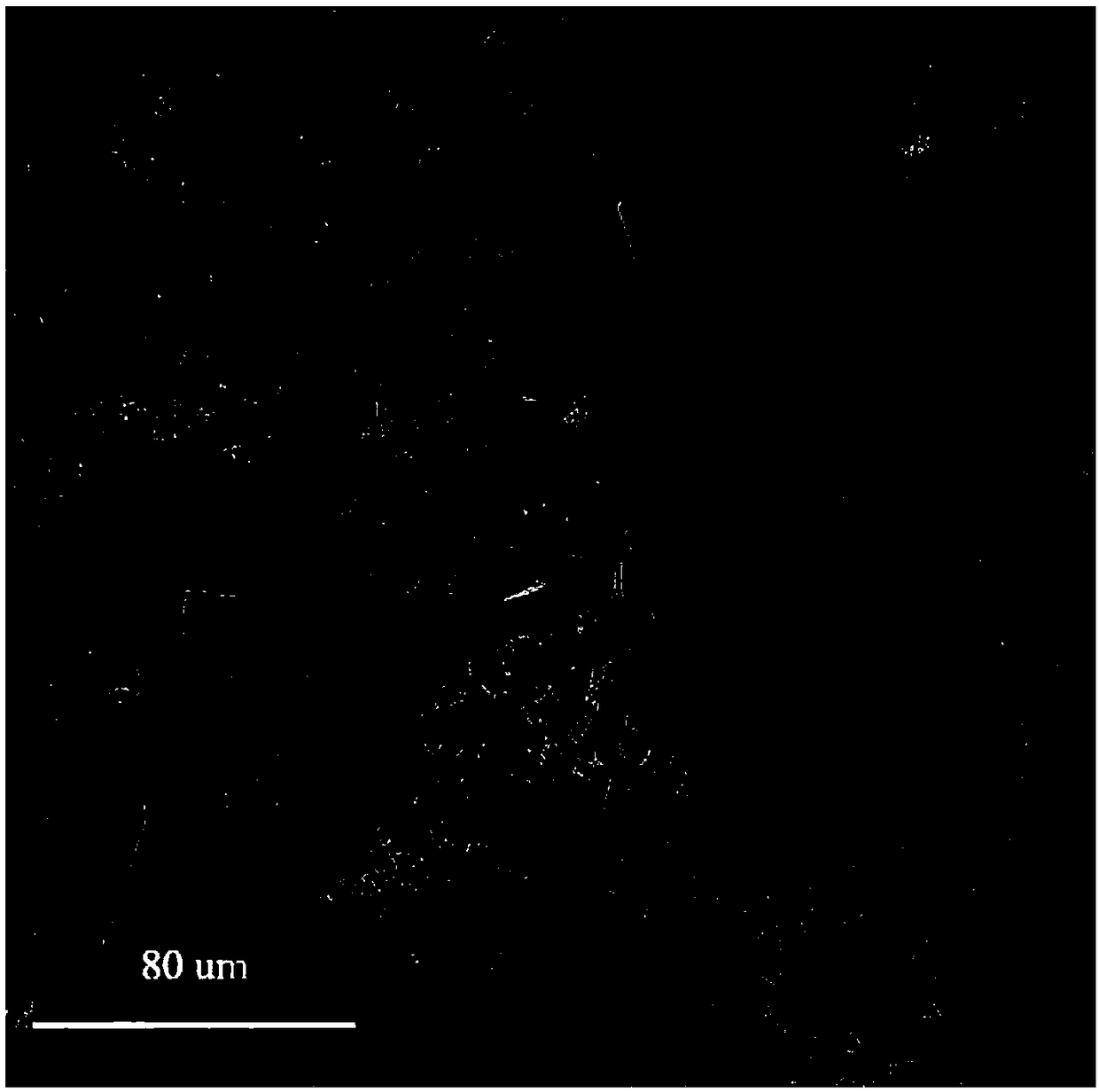

[0063] (1) Under an argon protective atmosphere, add TiB with a volume ratio of 1:1 to the stirring mill 2 Powder and Ni-based alloy powder, then add industrial alcohol of 2 / 3 of the volume of the mixing tank as a process control agent, add polyethylene glycol as a binder, wherein the mass ratio of polyethylene glycol to mixed powder is 10:100, and finally Add zirconia balls as the grinding medium, then grind for 4 hours at a speed of 800rpm to obtain the slurry of co...

Embodiment 3

[0069] This embodiment provides a kind of TiB for thermal spraying 2 - Ni-based metal-ceramic composite structure feeding material and preparation method thereof, the metal-ceramic nano-composite structure feeding material is made of TiB 2 It is prepared by combining spray drying and plasma spheroidization technology with a volume ratio of 1:1 with Ni-based alloy.

[0070] A kind of TiB for thermal spraying 2 -Ni base cermet composite structure feeding material and preparation method thereof, comprising the steps of:

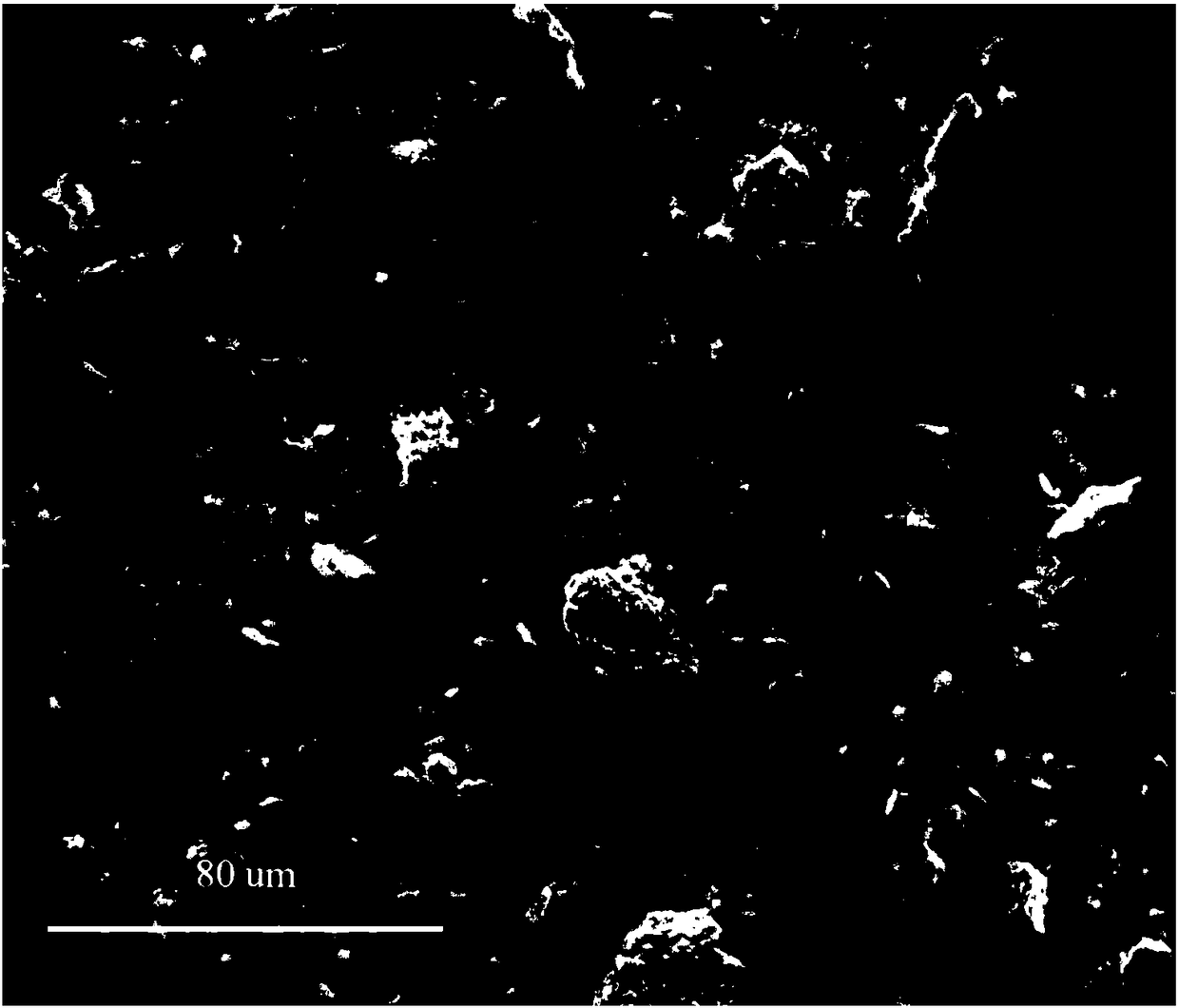

[0071] (1) Under an argon protective atmosphere, add TiB with a volume ratio of 1:1 to the stirring mill 2 powder and Ni-based alloy powder, then add industrial alcohol of 2 / 3 of the volume of the mixing tank as a process control agent, add polyethylene glycol as a binder, wherein the mass ratio of polyethylene glycol to mixed powder is 20:100, and finally Add zirconia balls as the grinding medium, then grind for 4 hours at a speed of 800rpm to obtain the slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com