Preparation method of low naphthalene high boiling point aromatic hydrocarbon solvent for rubber resin plasticizer

A high-boiling-point aromatic hydrocarbon and rubber resin technology, applied in chemical instruments and methods, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problem of low yield of solvents with low boiling point of naphthalene, and achieve environmental protection and low production cost , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

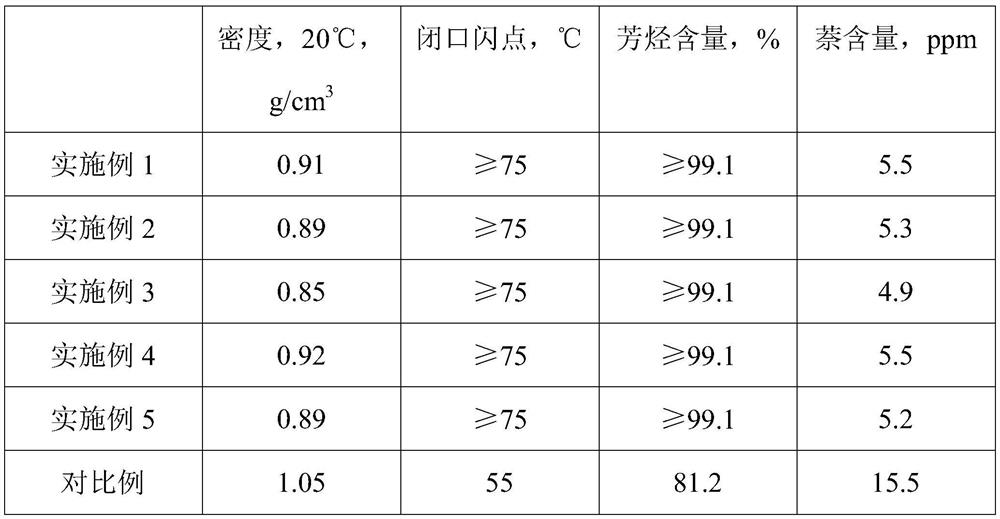

Examples

Embodiment 1

[0028] A preparation method for a low-naphthalene high-boiling-point aromatic hydrocarbon solvent for rubber resin plasticizers, comprising the following steps:

[0029] (1) Mix molybdenum disulfide powder and isopropanol, ultrasonically treat for 1 hour under the power of 1000W, then dropwise add silane coupling agent, continue ultrasonic treatment for 30min, and obtain modified molybdenum disulfide; wherein, molybdenum disulfide powder, The mass ratio of silane coupling agent is 1:0.003;

[0030] (2) Dissolve cobalt nitrate and nickel nitrate in deionized water, then add tartaric acid and stir to make mixed solution A; dissolve tetrabutyl titanate in absolute ethanol to make mixed solution B; After dropping the sodium hydroxide solution, continue to add the mixed solution B dropwise. After the dropwise addition, reflux at 60-70°C for 10 hours. After the reaction, cool to room temperature, filter, and dry. The dried solid and modified molybdenum disulfide Mix and grind in a ...

Embodiment 2

[0036] A preparation method for a low-naphthalene high-boiling-point aromatic hydrocarbon solvent for rubber resin plasticizers, comprising the following steps:

[0037] (1) Mix molybdenum disulfide powder and isopropanol, ultrasonically treat for 3 hours under the power of 1000W, then dropwise add silane coupling agent, continue ultrasonic treatment for 30min, and obtain modified molybdenum disulfide; wherein, molybdenum disulfide powder, The mass ratio of silane coupling agent is 1:0.006;

[0038] (2) Dissolve cobalt nitrate and nickel nitrate in deionized water, then add tartaric acid and stir to make mixed solution A; dissolve tetrabutyl titanate in absolute ethanol to make mixed solution B; After dropping the sodium hydroxide solution, continue to add the mixed solution B dropwise. After the dropwise addition, reflux at 60-70°C for 20 hours. After the reaction, cool to room temperature, filter, and dry. The dried solid and modified molybdenum disulfide The mixed grinding...

Embodiment 3

[0044] A preparation method for a low-naphthalene high-boiling-point aromatic hydrocarbon solvent for rubber resin plasticizers, comprising the following steps:

[0045] (1) Mix molybdenum disulfide powder with isopropanol, ultrasonically treat it for 1.5h at a power of 1000W, then add a silane coupling agent dropwise, and continue ultrasonic treatment for 30min to obtain modified molybdenum disulfide; wherein, molybdenum disulfide powder , The mass ratio of silane coupling agent is 1:0.004;

[0046] (2) Dissolve cobalt nitrate and nickel nitrate in deionized water, then add tartaric acid and stir to make mixed solution A; dissolve tetrabutyl titanate in absolute ethanol to make mixed solution B; After dropping the sodium hydroxide solution, continue to add the mixed solution B dropwise. After the dropwise addition, reflux at 60-70°C for 12 hours. After the reaction, cool to room temperature, filter, and dry. The dried solid and modified molybdenum disulfide Mix and grind in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com