Preparation method of positively-charged ceramic micro-nano fiber membrane

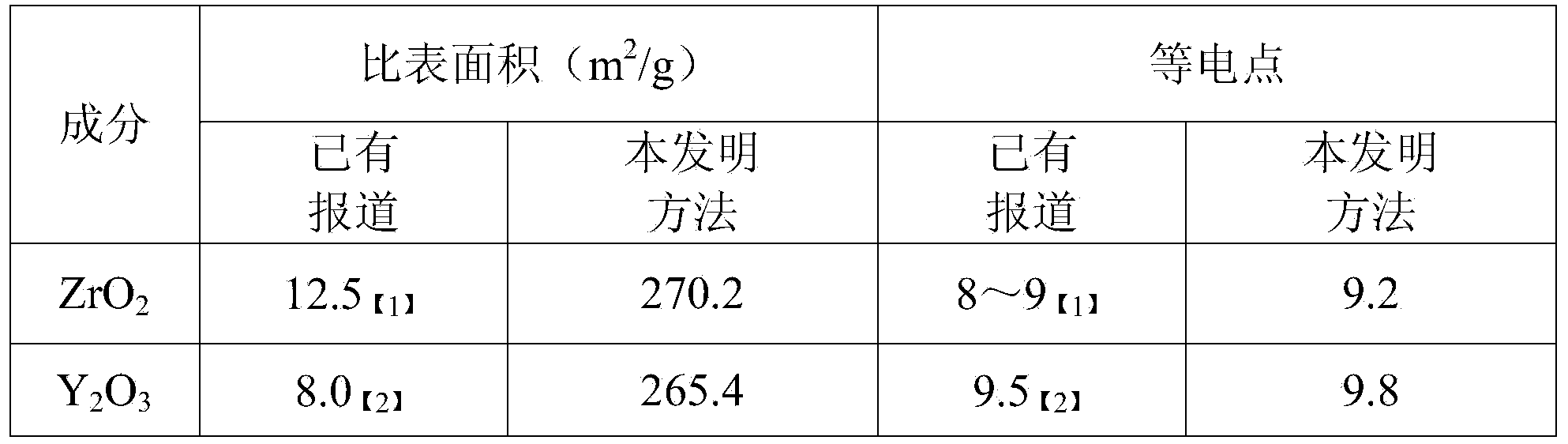

A nanofiber membrane, ceramic microtechnology, applied in the chemical characteristics of fibers, rayon manufacturing, heating/cooling fabrics, etc. Effects of porosity, high specific surface area, and high surface electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

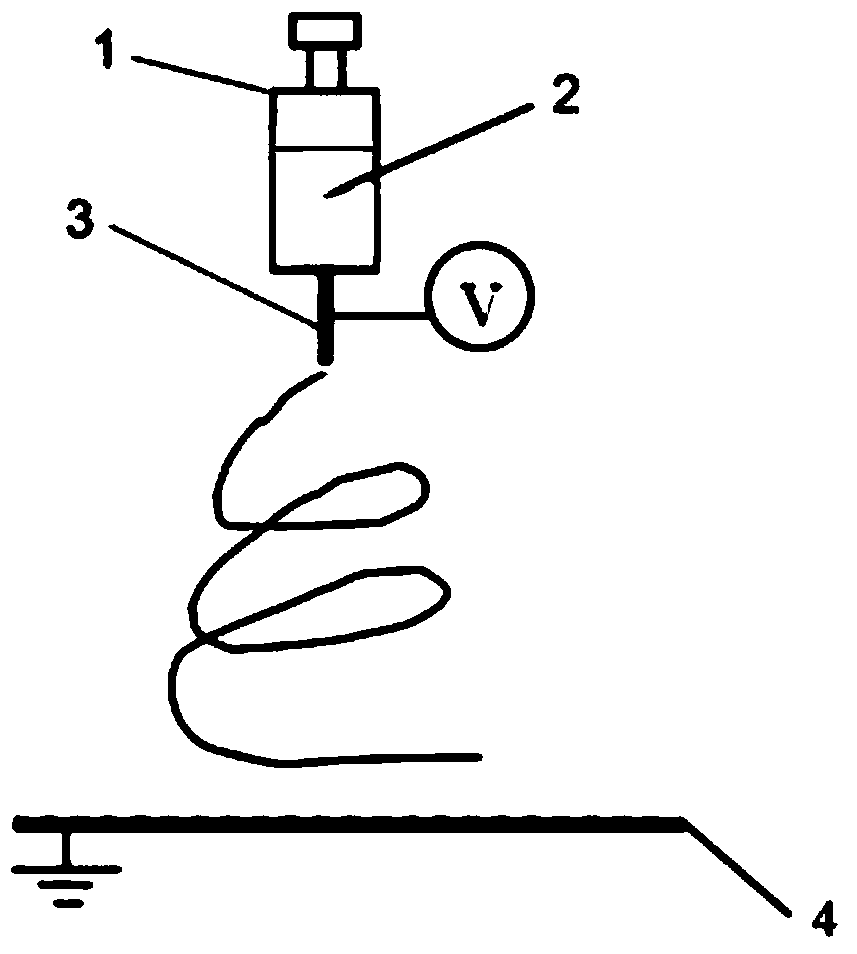

[0030] The preparation method of the positively charged ceramic micro-nano fiber membrane of the present invention is specifically implemented according to the following steps:

[0031] Step 1, prepare spinning solution

[0032] The spinning solution is composed of solute and solvent, the mass ratio of solvent to solute is 90-60:10-40, the solute is composed of spinnable polymer and ceramic precursor, and the weight ratio of ceramic precursor to spinnable polymer is 35-65 : 65~35, firstly add the spinnable polymer in the solvent, then add the ceramic precursor, stir and age to obtain the spinning solution;

[0033] The solvent is any one of water, ethanol, N, N dimethylformamide; the ceramic precursor is zirconium oxychloride, zirconium nitrate, zirconium chloride, zirconium acetate, yttrium chloride, yttrium nitrate, iron nitrate, nitric acid Any one of ferrous, ferrous chloride, ferric chloride, zinc nitrate, zinc acetate, zinc chloride, magnesium nitrate, magnesium chlorid...

Embodiment 1

[0040] Step 1, first dissolve 3.5g polyvinylpyrrolidone in 90g deionized water, then add 6.5g yttrium chloride, stir and age to obtain spinning solution;

[0041] Step 2, pour the spinning solution obtained in step 1 into a micropump, and use a flattened injection needle as a nozzle for electrospinning to obtain a composite fiber. The spinning voltage is 10kV, the collection distance is 30cm, and the spinning solution advance speed is 0.5 mL / h, the composite fiber is composed of yttrium chloride and polyvinylpyrrolidone;

[0042] Step 3, put the composite fiber obtained in step 2 in N 2 / O 2 (O 2The volume fraction is 50%) and calcined at 200°C in an atmosphere, and then in N 2 / H 2 (H 2 The volume fraction is 10%) and calcined at 400°C for 1h to obtain positively charged Y 2 o 3 micro-nanofibrous membrane.

Embodiment 2

[0044] Step 1, first dissolve 19.5g polyvinyl alcohol in 70g deionized water, then add 10.5g zirconium oxychloride, stir and age to obtain spinning solution;

[0045] Step 2, pour the spinning solution obtained in step 1 into a micropump, and use a flattened injection needle as a nozzle for electrospinning to obtain a composite fiber. The spinning voltage is 40kV, the collection distance is 10cm, and the spinning solution advance speed is 2.5 mL / h, the composite fiber is composed of zirconium oxychloride and polyvinyl alcohol;

[0046] Step 3, put the composite fiber obtained in step 2 in N 2 / O 2 (O 2 The volume fraction is 10%) and calcined at 300°C in an atmosphere, and then in N 2 Calcined at 700 °C for 5 h in the atmosphere to obtain positively charged ZrO 2 micro-nanofibrous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com