Impregnation agent for surface modification of nickel base alloy and utilization method of impregnation agent

A technology of surface modification and nickel-based alloy, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., to achieve the effect of easy realization, good bonding force and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

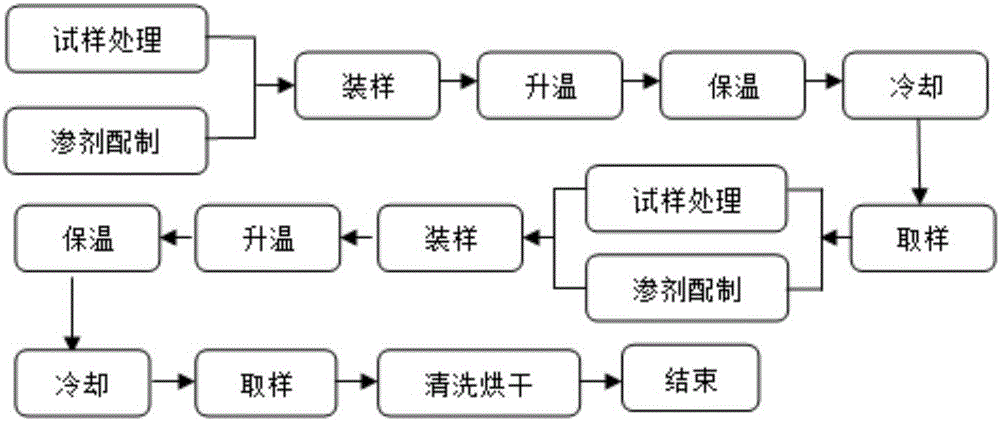

[0035] Such as figure 1 As shown, the process of adopting the technical solution of the present invention is as follows: 1. Alkali washing: the DZ125 alloy sample is placed in a 65° C. alkali washing liquid for 15 minutes, and the alkali washing liquid is 100 g / L NaOH solution; 2. Water washing: Rinse the sample after alkali washing with running water and dry it; ③ Preparation of penetrating agent: Accurately weigh the penetrating agent according to the amount, and the proportion of Al-Y penetrating agent by weight percentage is: 12% Al, 7% NH 4 Cl (analytically pure), 1% Y 2 o 3 , the balance being Al 2 o 3 ; The proportion of Cr-Y penetration agent is by weight percentage: 15% Cr, 7% NH 4 Cl (analytically pure), 1% Y 2 o 3 , the balance being Al 2 o 3 ; ④ ball milling: place the prepared Al-Y osmotic agent and Cr-Y osmotic agent in a ball mill for grinding, make them fully mixed, and refine the osmotic agent particles; ⑤ drying: place the osmotic agent after ball mil...

Embodiment 2

[0037] Such as figure 1 As shown, the method flow process adopting the technical solution of the present invention is: 1. alkali washing: the DZ125 alloy sample is placed in a temperature of 70 ℃ of alkali washing liquid, soaked for 13min, and the alkali washing liquid is 20g / L Na 3 PO 4 solution; ②Water washing: rinse the sample after alkali washing with flowing water, and dry it; ③Preparation of osmotic agent: accurately weigh the osmotic agent according to the amount, and the proportioning of Al-Y osmotic agent is as follows: 10% Al, 6%NH 4 Cl (analytical pure), 1.5% Y 2 o 3 , the balance being Al 2 o 3 ; The proportion of Cr-Y penetration agent is by weight percentage: 10% Cr, 6% NH 4 Cl (analytical pure), 1.5% Y 2 o 3 , the balance being Al 2 o 3 ; ④ ball milling: place the prepared Al-Y osmotic agent and Cr-Y osmotic agent in a ball mill for grinding, make them fully mixed, and refine the osmotic agent particles; ⑤ drying: place the osmotic agent after ball mil...

Embodiment 3

[0039] Such as figure 1 As shown, the method flow for adopting the technical solution of the present invention is: 1. Alkali washing: the DZ125 alloy sample is placed in an alkali washing solution with a temperature of 80° C., soaked for 10 minutes, and the alkali washing solution is 75 g / L NaOH solution; 2. Water washing: Rinse the sample after alkali washing with running water and dry it; ③ Preparation of penetrating agent: accurately weigh the penetrating agent according to the amount, and the proportion of Al-Y penetrating agent is as follows: 15% Al, 10% NH 4 Cl (analytical pure), 2% Y 2 o 3 , the balance being Al 2 o 3 ; The proportion of Cr-Y penetration agent is by weight percentage: 18% Cr, 10% NH 4 Cl (analytical pure), 2% Y 2 o 3 , the balance being Al 2 o 3 ; ④ ball milling: place the prepared Al-Y osmotic agent and Cr-Y osmotic agent in a ball mill for grinding, make them fully mixed, and refine the osmotic agent particles; ⑤ drying: place the osmotic agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com