A high temperature and corrosion resistant sinking roller and its manufacturing method

A manufacturing method and anti-corrosion technology, which is applied in coating, melt spraying, metal material coating technology, etc., can solve the problem that sinking rollers are easily damaged by corrosion, achieve good wear resistance, slow down corrosion speed, and reduce wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0056] Table 1 is the material and process parameter data of embodiment and comparative example;

[0057] Table 2 is a comparison of the performance of the sink rolls of the examples and the comparative examples.

[0058] Table 1

[0059]

[0060] Table 1 (continued)

[0061]

[0062] Table 2 (√ stands for qualified, × stands for unqualified)

[0063] category Coating Toughness Coating high temperature wear resistance Coating high temperature corrosion resistance Sinking roller life Example 1 √ √ √ 120h Example 2 √ √ √ 150h Example 3 √ √ √ 132h Comparative example 1 √ √ × 96h Comparative example 2 √ × √ 80h Comparative example 3 × × × 72h

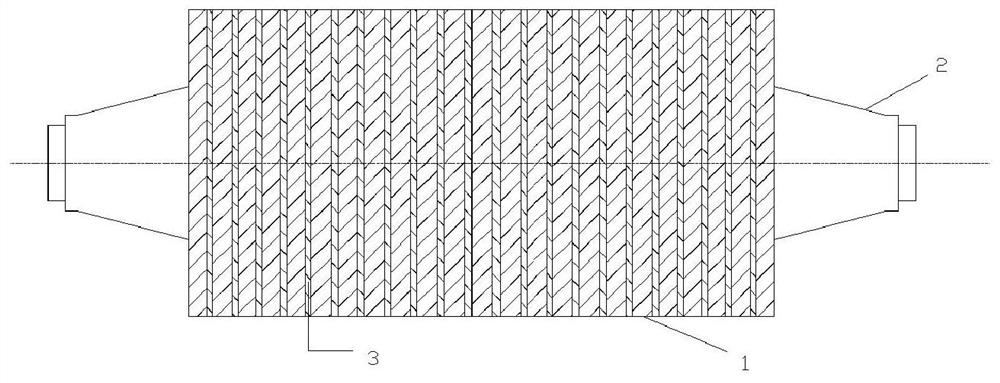

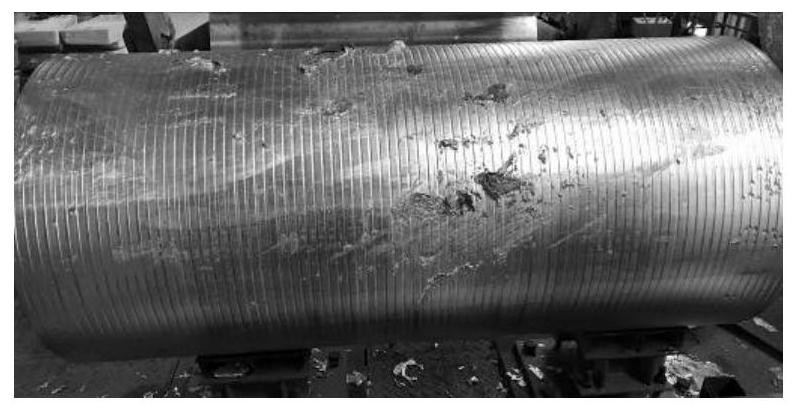

[0064] figure 1 It is a structural schematic diagram of the sinking roller of the present application, figure 2 For the sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com