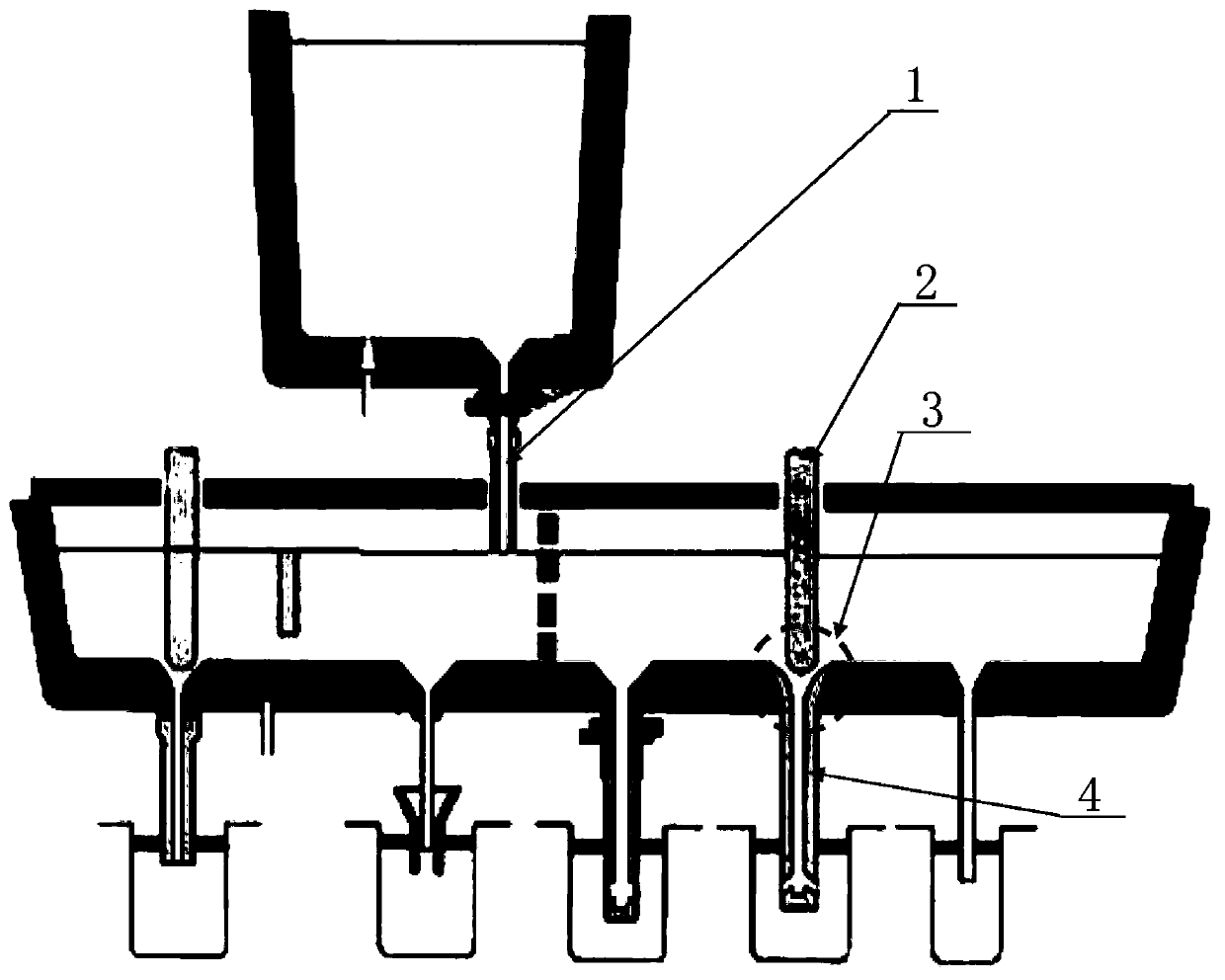

Long-life anticorrosive submersed nozzle for smelting stainless steel, and production method thereof

A corrosion-resistant, long-life technology, used in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problem of corrosion resistance at the slag line, the spalling performance cannot meet the requirements, the flow of molten steel cannot be controlled, and the melting loss rate is fast. and other problems, to achieve the effect of improving high temperature corrosion resistance, obvious service life and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Various raw materials are proportioned by weight: 26 parts of calcium oxide stabilized zirconia 40 mesh, 28 parts of calcium oxide stabilized zirconia 100 mesh, 20 parts of calcium oxide stabilized zirconia 325 mesh, 10 parts of baddeleyite 325 mesh, 8 parts of 598 flake graphite, 1 part of 98SiC powder, 3 parts of metal Si powder, B 4 C powder is 1 part, calcium hexaaluminate 180 mesh is 3 parts, liquid resin is 8 parts, and solid resin powder is 1 part.

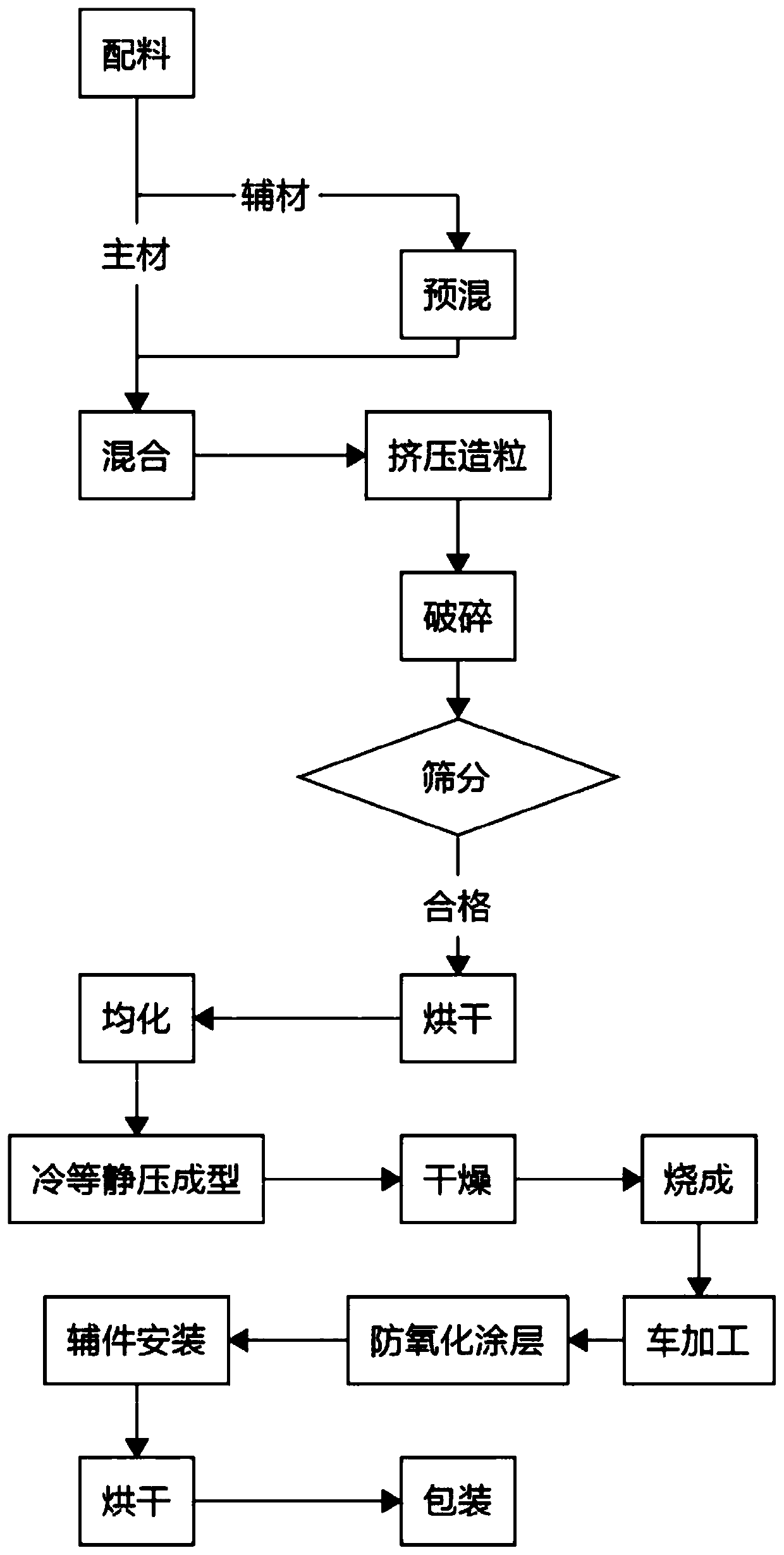

[0039]The production method of the submerged nozzle with corrosion resistance and long service life, the production method of the sludge at the slag line part includes the following steps:

[0040] 1) Weigh the ingredients according to the raw material composition, particle size and weight ratio, the tolerance is less than 0.02 kg, and seal it for later use;

[0041] 2) 10 parts of baddeleyite 325 mesh, 98SiC powder, metal Si powder, B 4 C powder, calcium hexaaluminate 180 mesh, solid resin powder, pre-mixed with a...

Embodiment 2

[0047] Various raw materials are proportioned by weight: 28 parts of calcium oxide stabilized zirconia 40 mesh, 26 parts of calcium oxide stabilized zirconia 100 mesh, 34 parts of calcium oxide stabilized zirconia 325 mesh, 10 parts of normal 598 flake graphite, 3 parts of 98SiC powder, 2 parts of metal Si powder, B 4 C powder is 2 parts, calcium hexaaluminate 180 mesh is 5 parts, liquid resin is 6 parts, and solid resin powder is 1.5 parts.

[0048] The production method of the submerged nozzle with corrosion resistance and long life: 7 parts of calcium oxide stabilized zirconia 325 mesh, 98SiC powder, metal Si powder, B 4 C powder, calcium hexaaluminate 180 mesh, solid resin powder are used as premixed powder, others are mixed as main ingredients, and the remaining methods are the same as in Example 1.

Embodiment 3

[0050] Various raw materials are proportioned by weight: 22 parts of calcium oxide stabilized zirconia or baddeleyite 40 mesh, 14 parts of calcium oxide stabilized zirconia 100 mesh, 8 parts of baddeleyite 100 mesh, 325 parts of calcium oxide stabilized zirconia Mesh is 8 parts, baddeleyite 325 mesh is 18 parts, normal 598 flake graphite is 13 parts, 98SiC powder is 4 parts, metal Si powder is 4 parts, B 4 C powder is 2.5 parts, calcium hexaaluminate 180 mesh 4 parts, liquid resin is 5 parts, and solid resin powder is 0.5 parts.

[0051] The production method of the submerged nozzle with corrosion resistance and long life: 18 parts of baddeleyite 325 mesh, 98SiC powder, metal Si powder, B 4 C powder, calcium hexaaluminate 180 mesh, and solid resin powder are used as premixed powder, and others are mixed as main ingredients, and the rest of the method is the same

[0052] Example 1.

[0053] In the embodiment of the present invention, 60 casters are used in the 1450 casting m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com