Environment-friendly vent cap for high-speed gearbox

A technology for gear boxes and vent caps, applied in gear lubrication/cooling, belts/chains/gears, coatings, etc., can solve environmental pollution and other problems, achieve the effects of reducing environmental pollution, improving separation effect, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

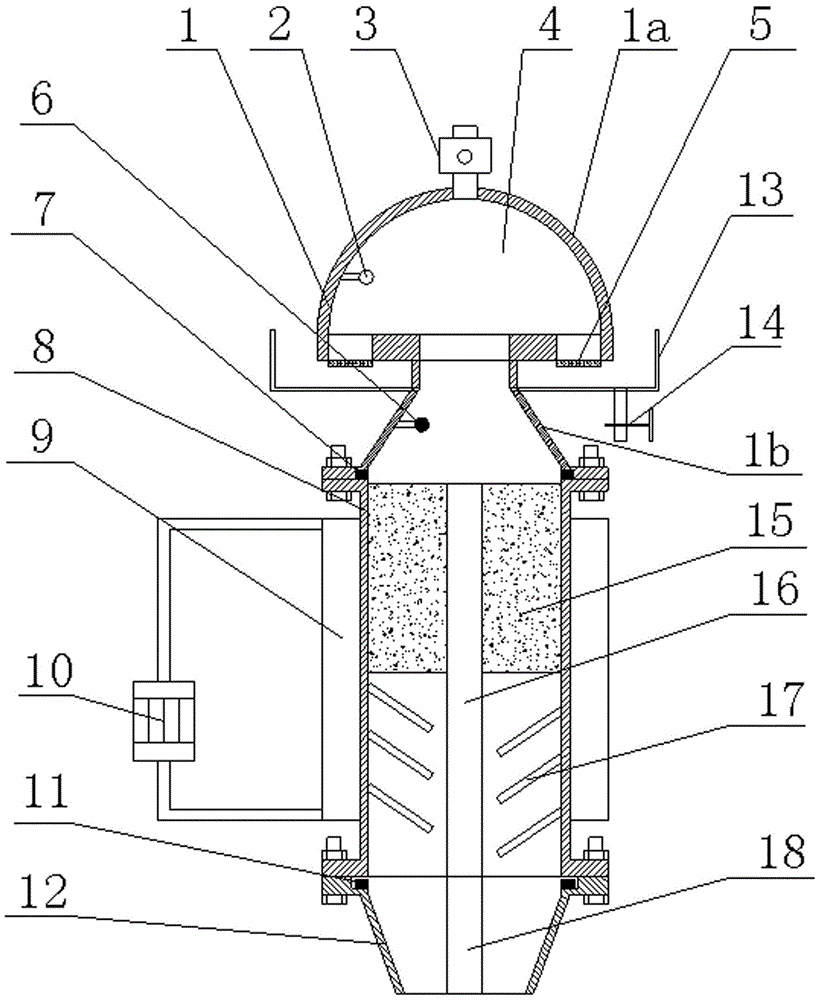

[0054] The high-speed gearbox of the present embodiment uses the environment-friendly ventilation cap, as figure 1 As shown, it includes a ventilation cover 1, a ventilation pipe 8 and a base 12, the ventilation cover 1 is fixedly connected to the upper end of the ventilation pipe 8, and the base 12 is fixedly connected to the lower end of the ventilation pipe 8.

[0055] The high-speed gear box of the present embodiment uses the cover body 1a of the vent cover 1 upper end of the environmental protection vent cap to be made hemispherical and the interior is shaped on cavity 4, and the lower end of vent cover 1 is shaped on vent cover connecting portion 1b, and vent cover connecting portion 1b It is connected with the upper end of the ventilation pipe 8 by bolts, and the lower edge of the cover body 1a of the ventilation hood 1 is provided with an exhaust port, and a copper foam filter 5 is arranged at the exhaust port, and an oil collector 13 is arranged under the exhaust port ...

Embodiment 2

[0077] The environment-friendly breather cap for the high-speed gear box of the present embodiment is basically the same as that of the first embodiment, except that the mass percent of each component in the raw material of the oil baffle is: tungsten carbide: 1.31%, montmorillonite: 1.14%; kaolin : 2.75%; AlN: 1.23%, wollastonite: 1.55%, diopside: 1.12%, antioxidant RD: 0.65%, magnesium oxide: 1.34%, copper oxide: 0.62%, iron oxide: 0.43%, Fe: 0.46%, iron hydroxide: 0.14%, Al: 1.78%, Zn: 1.32%, Mn: 0.66%, Cr: 0.07%, Ni: 0.73%, Cu: 0.57%, Mo: 0.08%, Ti: 1.44%, Pd: 0.13%, Pt: 0.18%, W: 0.42%, Nd: 0.05%, Ce: 0.17%, Eu: 0.22%, Lu: 0.16%, Au: 0.27%, Ag: 0.58%, Ga: 0.06%, Sn: 1.34%, Zr: 0.09%, Re: 0.03%, and the balance is clay.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com