Energy-gathering and heat-insulating pot rack and production process thereof

A technology of production process and pot support, which is applied in the field of energy-gathering heat insulation pot support and its production process, can solve the problems of single function effect, unfavorable market competition, and inability to enhance the combustion efficiency of burners, so as to achieve enhanced high temperature resistance The ability to corrode and the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

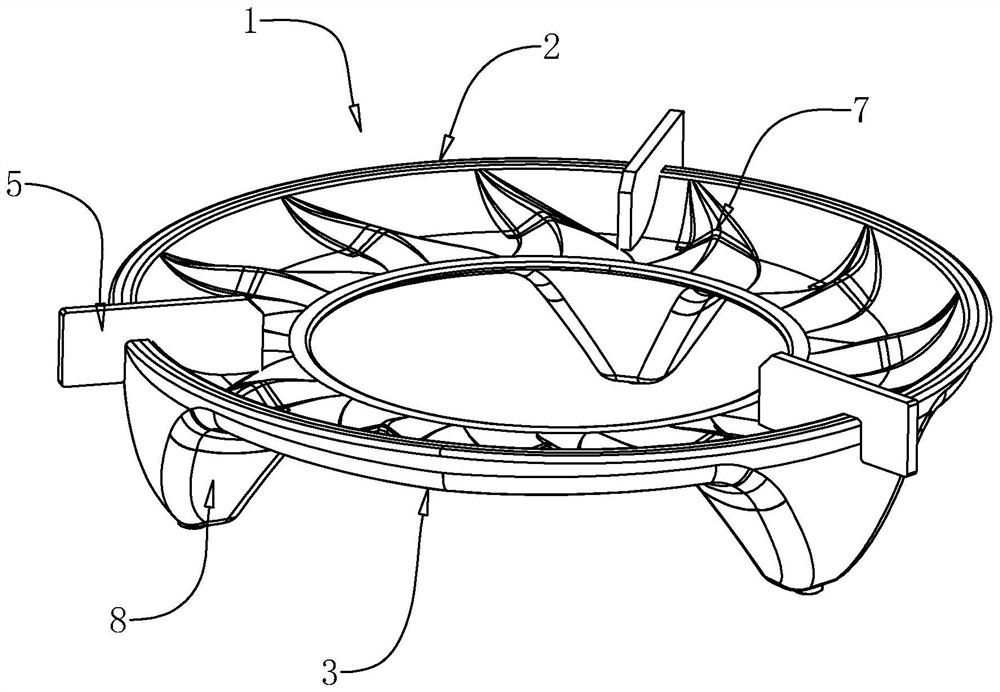

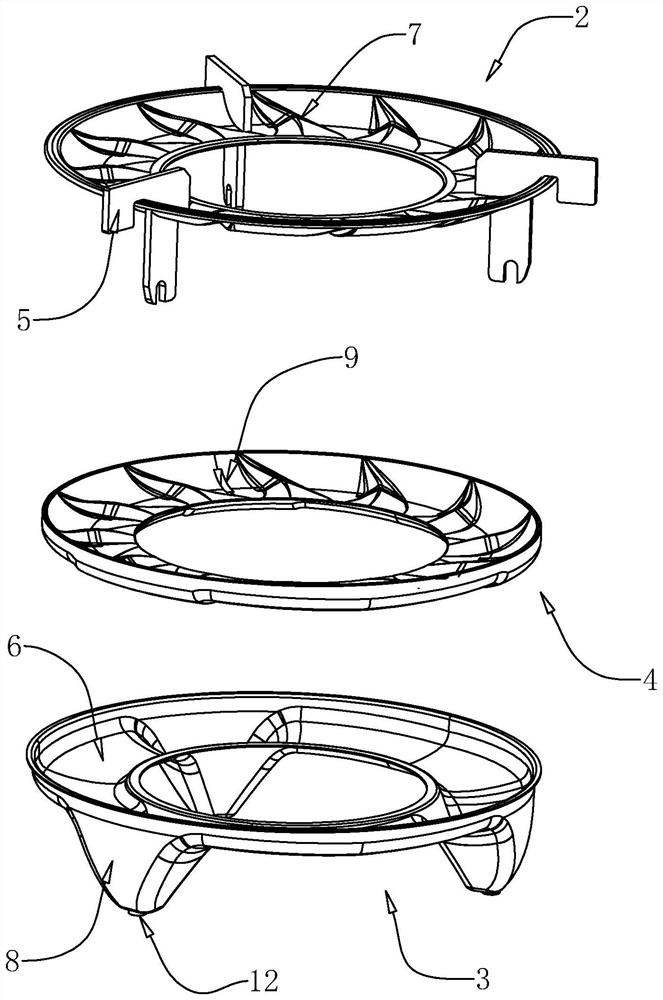

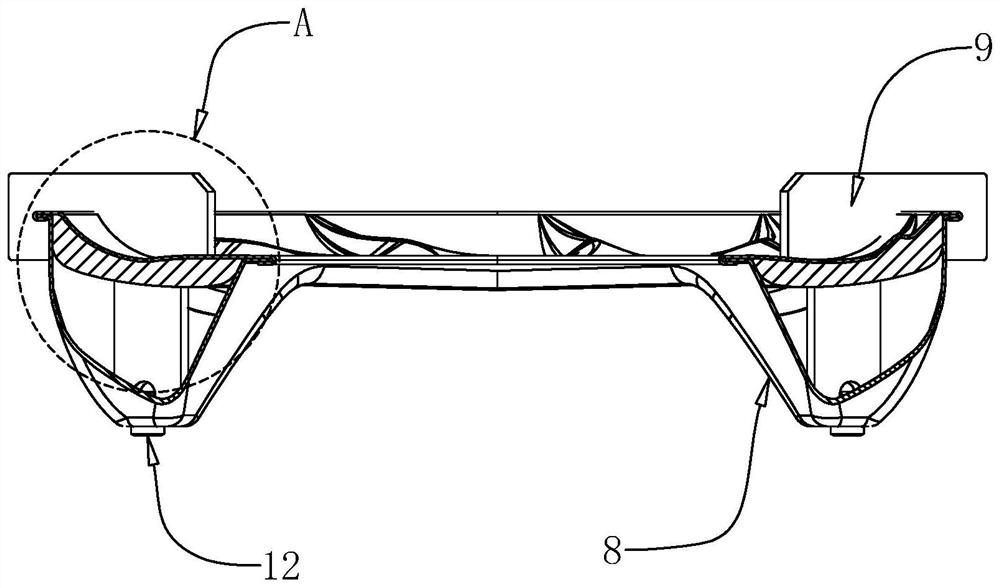

[0043] see Figure 1 to Figure 4 , an energy-gathering and heat-insulating pot support and a production process thereof of the present invention, the specific steps include:

[0044] S1: The upper cover plate 2 and the lower cover plate 3 are formed by stamping and stretching in a stamping die using SPCC cold plate material. Wherein, the upper cover plate 2 and the lower cover plate 3 are both annular structures, and the upper cover plate 2 and the lower cover plate 3 can be covered to form a hollow heat-insulating cavity 6, and the top surface of the upper cover plate 2 is concaved downward to form a The energy-gathering part, the energy-gathering part is also stamped in step S1 to form a number of Bernoulli fluid vortex shaped surfaces 7 bent towards the same side, and the several Bernoulli fluid vortex shaped surfaces 7 are flat at both ends and raised in the middle The structure of each Bernoulli fluid vortex shape surface 7 and the bottom surface of the energy gathering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com