Fireproof anti-corrosion coating material and preparation method thereof

A technology for anti-corrosion coatings and raw materials, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of high temperature resistance, low fire resistance, poor corrosion resistance, battery pack influence, etc., to improve water resistance and heat resistance, Improve fire and anti-corrosion performance, improve the effect of anti-corrosion and fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

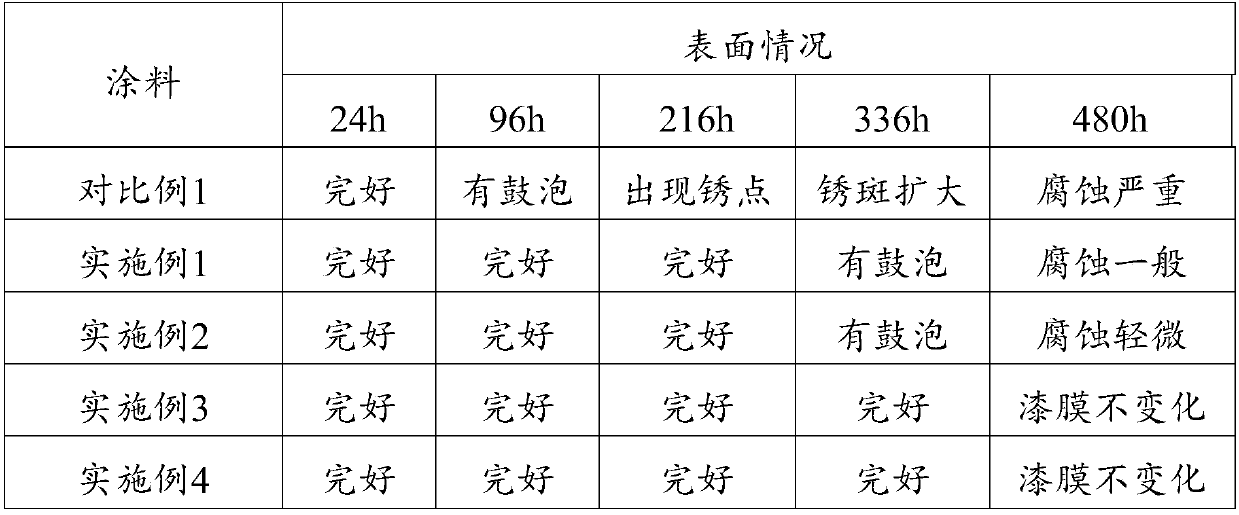

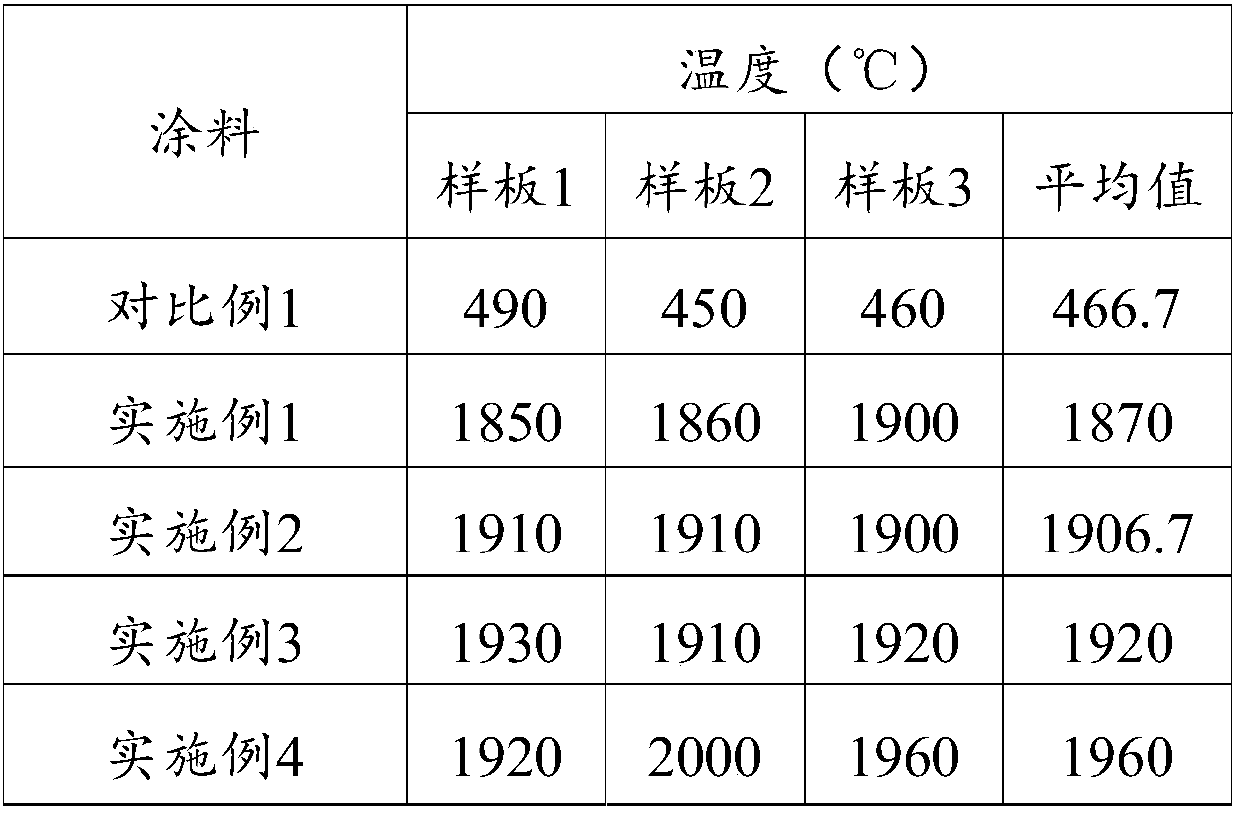

Examples

Embodiment 1

[0039] This embodiment provides a kind of fireproof and anticorrosion coating, and raw material component comprises:

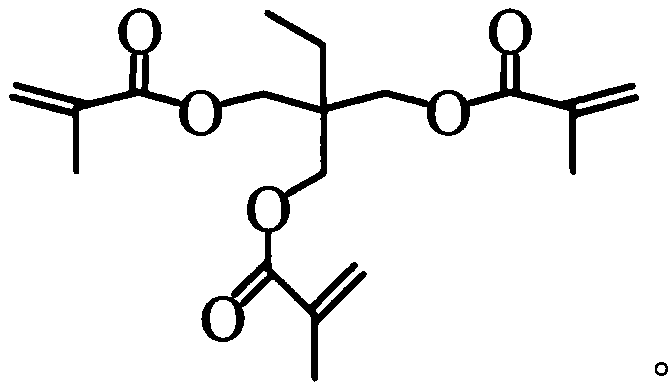

[0040] 31 parts by weight of butyl acrylate, 16 parts by weight of methyl methacrylate, 1 part by weight of glycidyl methacrylate, 1.1 parts by weight of acrylic acid, 1 part by weight of reactive emulsifier NRS-10, and 0.1 parts by weight of initiator potassium persulfate Parts, 1 part by weight of trimethylolpropane triacrylate, 6 parts by weight of polyazide silane, 1.5 parts by weight of spiral carbon fiber, 6 parts by weight of polysilsesquioxane, 0.01 part by weight of graphene, nano TiO 2 3 parts by weight, 25 parts by weight of ethanol, and 120 parts by weight of water.

[0041] The preparation method of described fireproof anticorrosion coating, comprises the steps:

[0042] (1) Preparation of acrylic resin aqueous solution

[0043] Add 70 parts by weight of water and 1 part by weight of NRS-10 into the stirring tank, stir and dissolve, add 11 parts b...

Embodiment 2

[0051] This embodiment provides a kind of fireproof and anticorrosion coating, and raw material component comprises:

[0052] 37 parts by weight of butyl acrylate, 13 parts by weight of methyl methacrylate, 1.5 parts by weight of glycidyl methacrylate, 2 parts by weight of acrylic acid, 1.5 parts by weight of reactive emulsifier NRS-10, 0.06 parts by weight of potassium persulfate, 3 parts by weight of trimethylolpropane triacrylate, 3 parts by weight of polyazinosilane, 2 parts by weight of spiral carbon fiber, 3 parts by weight of polysilsesquioxane, 0.1 part by weight of graphene, nano TiO 2 2 parts by weight, 27 parts by weight of ethanol, and 100 parts by weight of water.

[0053] The preparation method of described fireproof anticorrosion coating, comprises the steps:

[0054] (1) Preparation of acrylic resin aqueous solution

[0055] Add 75 parts by weight of water and 1.5 parts by weight of NRS-10 into the stirred tank, stir and dissolve, add 12 parts by weight of BA...

Embodiment 3

[0063] This embodiment provides a kind of fireproof and anticorrosion coating, and raw material component comprises:

[0064] 39 parts by weight of butyl acrylate, 13.5 parts by weight of methyl methacrylate, 1.5 parts by weight of glycidyl methacrylate, 2.5 parts by weight of acrylic acid, 1.8 parts by weight of reactive emulsifier NRS-10, 0.08 parts by weight of potassium persulfate, 4 parts by weight of trimethylolpropane triacrylate, 4 parts by weight of polyazinosilane, 2.5 parts by weight of spiral carbon fiber, 4 parts by weight of polysilsesquioxane, 0.15 parts by weight of graphene, nano-TiO 2 2.5 parts by weight, 35 parts by weight of ethanol, and 106 parts by weight of water.

[0065] The preparation method of described fireproof anticorrosion coating, comprises the steps:

[0066] (1) Preparation of acrylic resin aqueous solution

[0067] Add 78 parts by weight of water and 1.8 parts by weight of NRS-10 into the stirred tank, stir and dissolve, add 12 parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com