Preparation method of section steel ultra-light concrete member

A concrete and concrete layer technology, applied to building components, long strip structural components for load-bearing, structural elements, etc., can solve problems such as difficult to perfect functions, poor heat insulation and sound insulation, and loss of bearing capacity, etc., to achieve Improve mechanical properties and engineering applicability, delay corrosion, and improve seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0082] Take the fire resistance time limit τ=1.0h=3600s, t b =925°C, t w =350°C, t 0 =18°C

[0083]

[0084] Check the table to know:

[0085] Available: δ=0.015m=15mm

example 2

[0087] Take the fire resistance time limit τ=2.0h=7200s, t b =1029°C, t w =350°C, t 0 =18°C

[0088]

[0089] Check the table to know:

[0090] Available: δ=0.024m=24mm.

[0091] A method for preparing ultra-light concrete components with section steel, characterized in that the method includes a material preparation process, a grouting process, a curing process, a demoulding process, and a node connection structure installation process carried out in sequence;

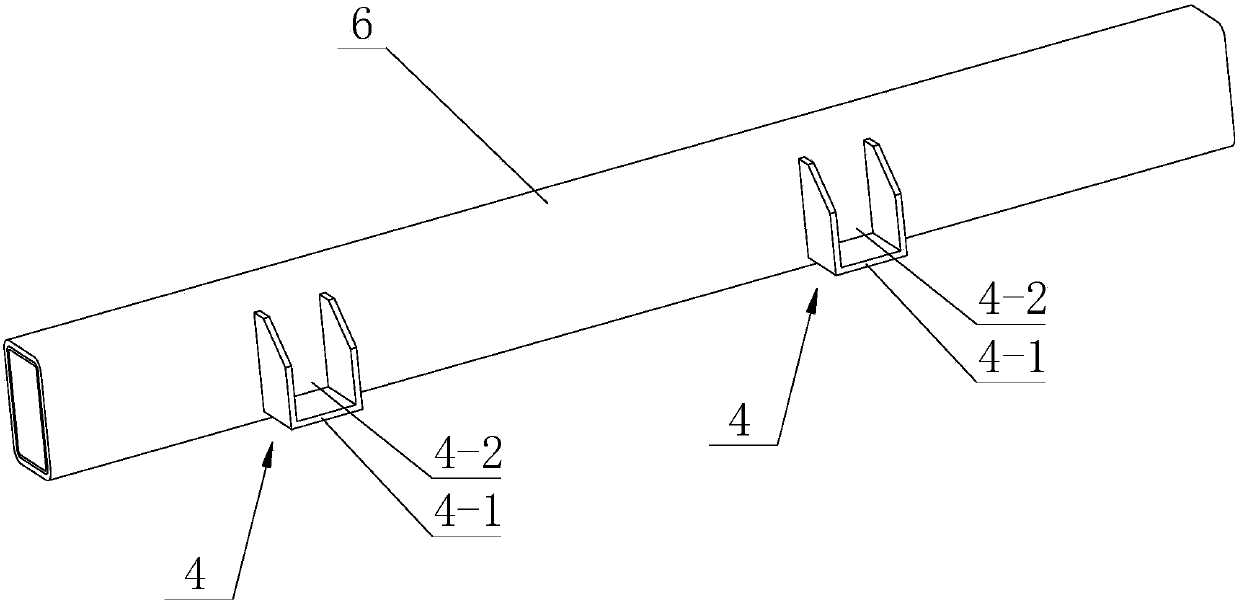

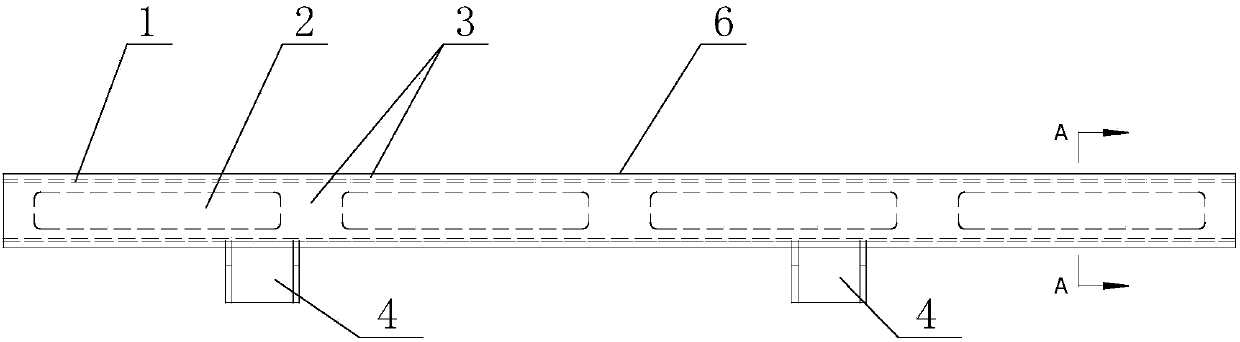

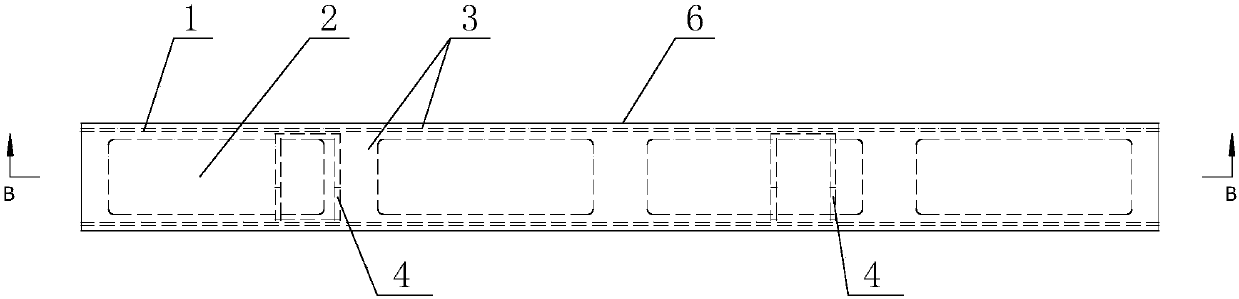

[0092] The material preparation process includes profile steel preparation, core material preparation, slurry preparation, facing layer material preparation and node connection structure preparation; the profile steel preparation includes straightening, blanking and drilling of the profile steel, and standby; the core material The preparation includes blanking the lightweight core material 2 and installing a positioner for standby; the slurry preparation refers to mixing and stirring the materials used to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com