Dry material for fire resistance

A dry-type material and refractory technology, applied in the field of refractory materials, can solve the problems of poor corrosion resistance, shedding and high cost of dry-type materials, improve seismic performance and thermal stability, enhance high temperature and corrosion resistance, and improve Density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

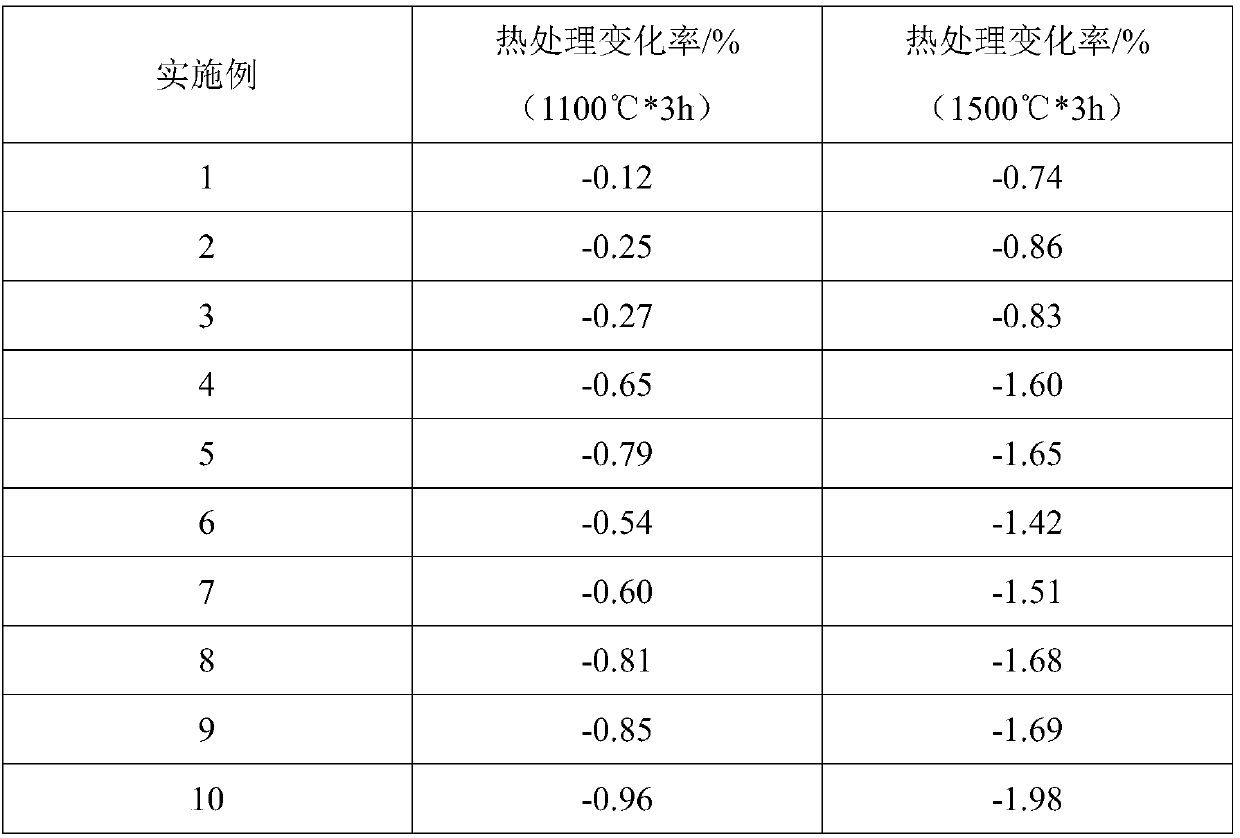

Examples

preparation example Construction

[0054] In a specific embodiment, the preparation method of the phenolic resin comprises the following steps:

[0055] Weigh phenol, methyl p-hydroxyphenylpropionate, boric acid, hydrochloric acid and toluene, heat the system to 180-200°C, remove water, cool down to 90°C, add paraformaldehyde, heat to 100-120°C, and react After 30 minutes to 1 hour, remove water to obtain phenolic resin.

[0056] In a preferred embodiment, the preparation method of the phenolic resin comprises the steps of:

[0057] Weigh the formulated amount of phenol, methyl p-hydroxyphenylpropionate, boric acid, hydrochloric acid and toluene, heat to 90°C to stabilize the reaction system, then gradually increase the temperature to 190°C within 5 hours until no liquid appears in the water separator , The water generated by the reaction was distilled off under reduced pressure, the temperature was lowered to 90°C, paraformaldehyde was added, heated to 110°C, reacted for 45min, and water was removed to obtain...

Embodiment 1

[0068] The first aspect of Example 1 provides a dry material for refractory, which comprises the following components in parts by weight:

[0069] 77 parts of magnesia; 18 parts of magnesia olive sand; 4 parts of high temperature binder A; 1.1 parts of high temperature binder B and 1 part of auxiliary agent;

[0070] The high-temperature binder A is a phenolic resin;

[0071] The high-temperature binder B is a silicon-titanium compound.

[0072] The second aspect of embodiment 1 provides a kind of preparation method of phenolic resin, comprises the steps:

[0073] Weigh the formulated amount of phenol, methyl p-hydroxyphenylpropionate, boric acid, hydrochloric acid and toluene, heat to 90°C to stabilize the reaction system, then gradually increase the temperature to 190°C within 5 hours until no liquid appears in the water separator , the water generated by the reaction was distilled off under reduced pressure, the temperature was lowered to 90°C, paraformaldehyde was added,...

Embodiment 2

[0078] The first aspect of Example 2 provides a dry material for refractory, which comprises the following components in parts by weight:

[0079] 60 parts of magnesia; 5 parts of magnesia olive sand; 3 parts of high temperature binder A; 0.2 parts of high temperature binder B and 0.5 parts of additives;

[0080] The high-temperature binder A is a phenolic resin;

[0081] The high-temperature binder B is a silicon-titanium compound.

[0082] The second aspect of embodiment 2 provides a kind of preparation method of phenolic resin, comprises the steps:

[0083] Weigh the formulated amount of phenol, methyl p-hydroxyphenylpropionate, boric acid, hydrochloric acid and toluene, heat to 90°C to stabilize the reaction system, then gradually increase the temperature to 190°C within 5 hours until no liquid appears in the water separator , the water generated by the reaction was distilled off under reduced pressure, the temperature was lowered to 90°C, paraformaldehyde was added, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com