High-temperature water-wet maintenance simulation test device and method of cement stone of thermal production well

A simulation test, cement stone technology, used in the preparation of test samples, the use of stable shear force to test the strength of materials, and the use of stable tension/pressure to test the strength of materials, etc. , can not fully simulate and reflect problems, to achieve the effect of reducing errors and improving experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

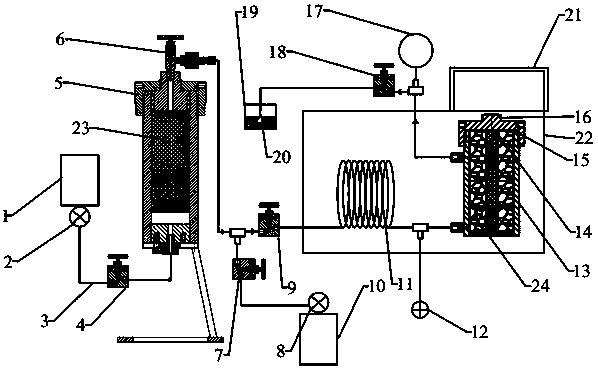

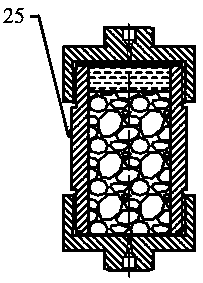

[0035] see figure 1 , figure 2 .

[0036] A thermal recovery well cement stone high-temperature water-humidity curing simulation test device, mainly composed of a nitrogen source 1, an intermediate water container 5, CO 2 Gas source 10, flowmeter 12, airtight kettle body A13, pressure gauge 17, condenser 19, heating furnace 22, airtight kettle body A13 is located in the heating furnace 22, there is a closed kettle cover A16 on the top, and the heating furnace 22 passes through the heating furnace The control box 21 regulates the temperature.

[0037] The well-maintained cement stone 24 is placed in the closed kettle body A13. There is a water inlet at the lower part of the side end of the kettle body A. The water inlet is respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com