Electrodeposited Ni-Co-Al-Cr high-temperature composite coating and preparation method thereof

A composite coating and electrodeposition technology, which is applied in the field of electrodeposited Ni-Co-Al-Cr high-temperature composite coating and its preparation, can solve the problems that the high-temperature composite coating has not yet been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

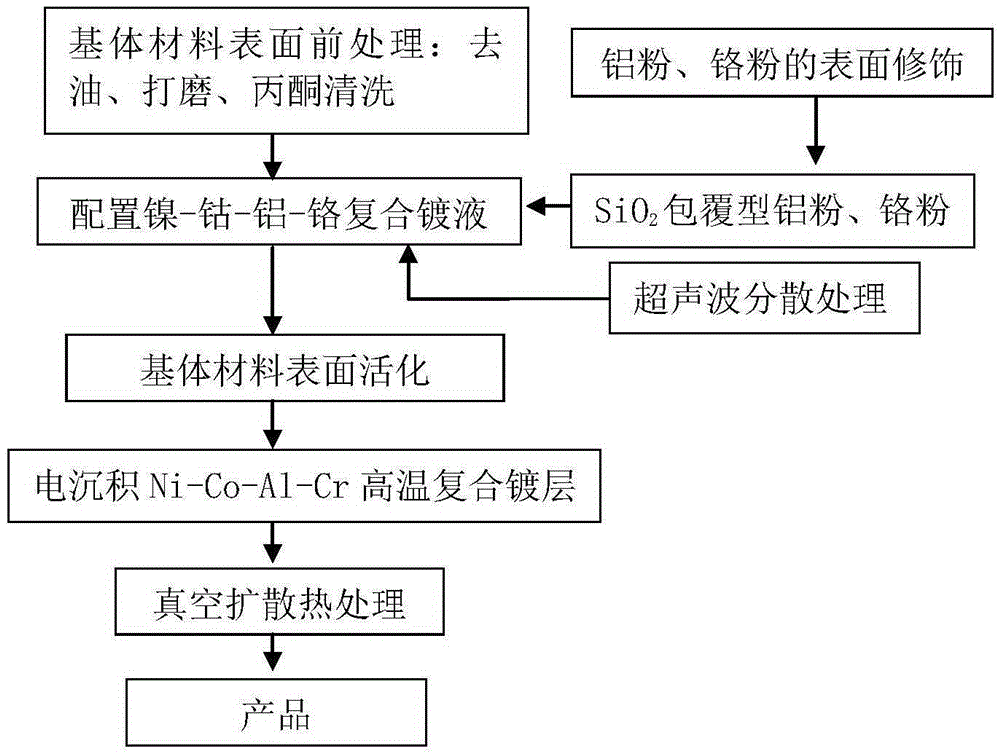

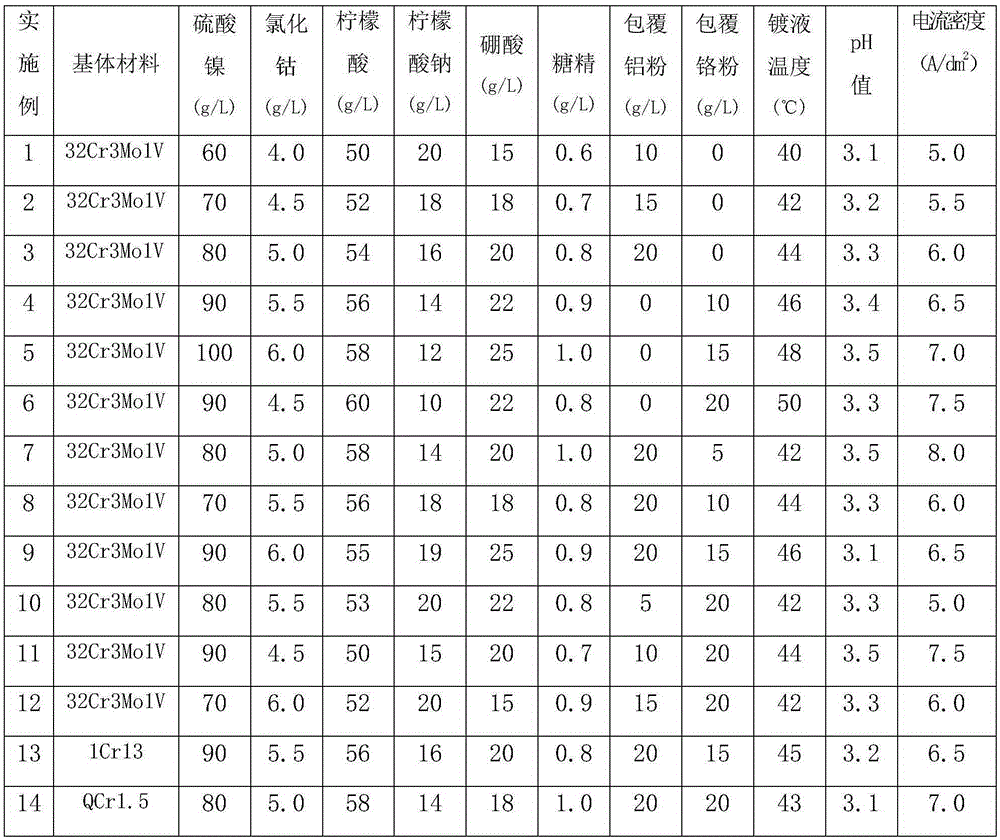

[0052] In conjunction with the figures and tables, a kind of electrodeposited Ni-Co-Al-Cr high temperature composite coating of the present invention and its preparation method, it adopts metal material to make substrate, earlier substrate surface is carried out pre-treatment, is prepared with nickel sulfate, cobalt chloride, Citric acid, trisodium citrate, and saccharin are the main components, with SiO 2 Coated aluminum powder and chromium powder are the composite plating solution of the dispersed phase. The composite plating solution is ultrasonically dispersed in an ultrasonic vibrator for 10 to 12 minutes. In the plating solution, through reasonable setting of the electrodeposition process parameters and sufficient stirring, the aluminum powder and chromium powder particles are evenly dispersed in the plating solution, and the aluminum powder, chromium powder particles and the matrix metal Ni and Co are co-deposited to form Ni-Co-Al-Cr high-temperature composite coating. ...

Embodiment 1

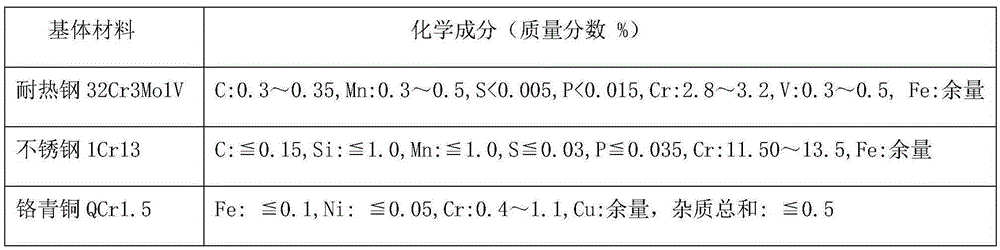

[0057] The base material is heat-resistant steel 32Cr3Mo1V, the chemical composition is shown in the figure (table), the sample size is: 20mm×12mm×2mm, the preparation operation steps of Ni-Co-Al-Cr high temperature composite coating on the surface of heat-resistant steel 32Cr3Mo1V:

[0058] ① Degreasing treatment on the surface of heat-resistant steel 32Cr3Mo1V, the formula is mass fraction: sodium hydroxide 18g / L, sodium carbonate 28g / L, sodium phosphate 8g / L, OP-10 emulsifier 1.5ml / L volume fraction; temperature 82°C ;

[0059] ② Rust removal treatment on the surface of heat-resistant steel 32Cr3Mo1V, the formula is: sulfuric acid 100ml / L volume fraction, hexamethylenetetramine 10g / L mass fraction, temperature 52°C;

[0060] ③ Use 180#, 360#, 600# sandpaper to polish the heat-resistant steel 32Cr3Mo1V after degreasing and derusting treatment in sequence, then use acetone to ultrasonically clean the surface of the substrate, and dry it for later use;

[0061] ④ Surface modi...

Embodiment 2

[0068] The base material is heat-resistant steel 32Cr3Mo1V, the chemical composition is shown in the figure (table), the sample size is: 20mm×12mm×2mm, the preparation operation steps of Ni-Co-Al-Cr high temperature composite coating on the surface of heat-resistant steel 32Cr3Mo1V:

[0069] ① Degreasing treatment on the surface of heat-resistant steel 32Cr3Mo1V, the formula is mass fraction: sodium hydroxide 18.5g / L, sodium carbonate 28.5g / L, sodium phosphate 8.5g / L, OP-10 emulsifier 2ml / L volume fraction; temperature 81°C;

[0070] ② Rust removal treatment on the surface of heat-resistant steel 32Cr3Mo1V, the formula is: sulfuric acid 102ml / L volume fraction, hexamethylenetetramine 10.5g / L mass fraction, temperature 51°C;

[0071]③ Use 180#, 360#, 600# sandpaper to polish the heat-resistant steel 32Cr3Mo1V after degreasing and derusting treatment in sequence, then use acetone to ultrasonically clean the surface of the substrate, and dry it for later use;

[0072] ④ Surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com