Method for preparing high-purity trifluoroiodomethane

A high-purity technology of trifluoroiodomethane, applied in the field of preparation of fluorine-containing organic compounds, can solve the problems such as the content of inorganic impurities is not clearly specified, and achieve the effects of stable and reliable preparation process, easy operation, and reasonable and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

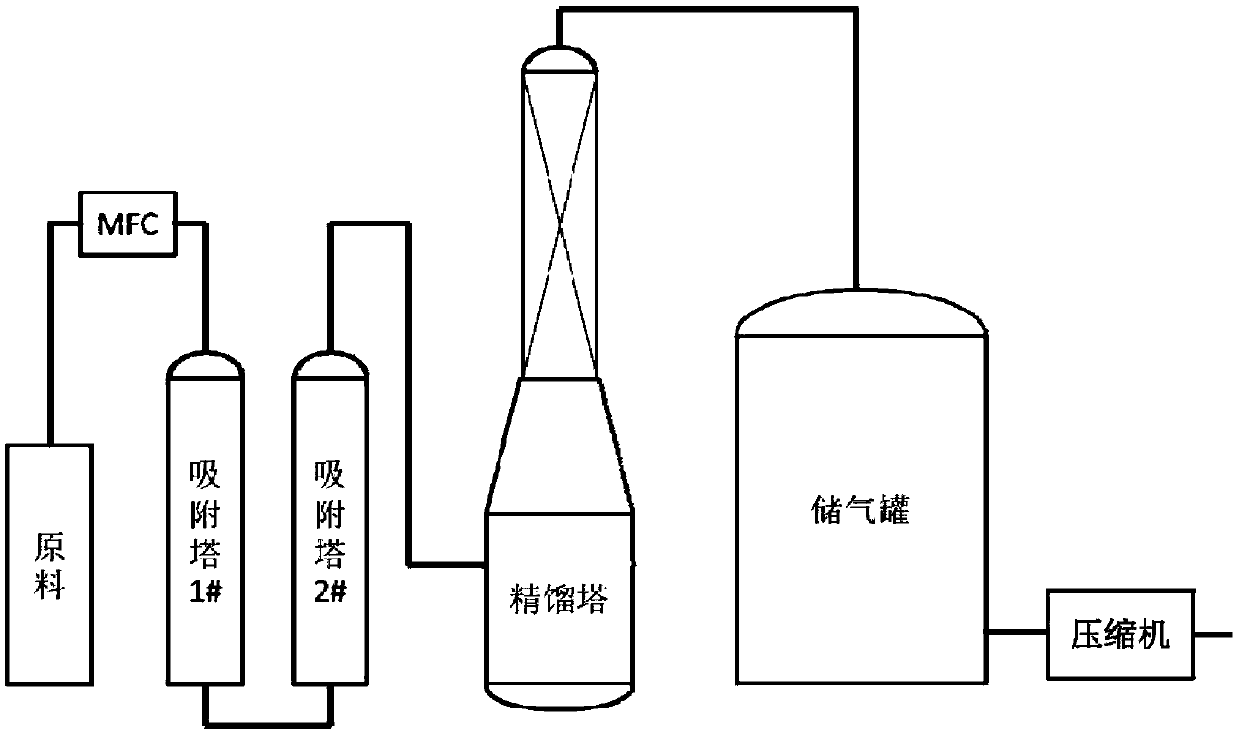

Method used

Image

Examples

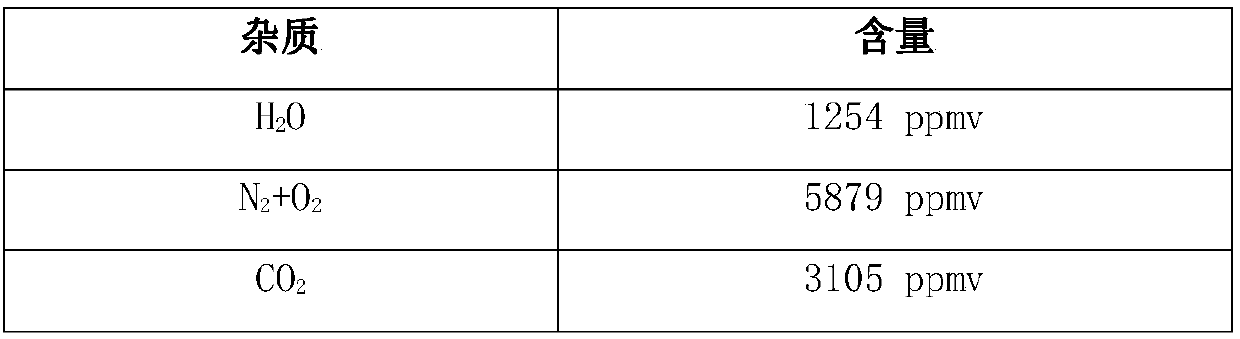

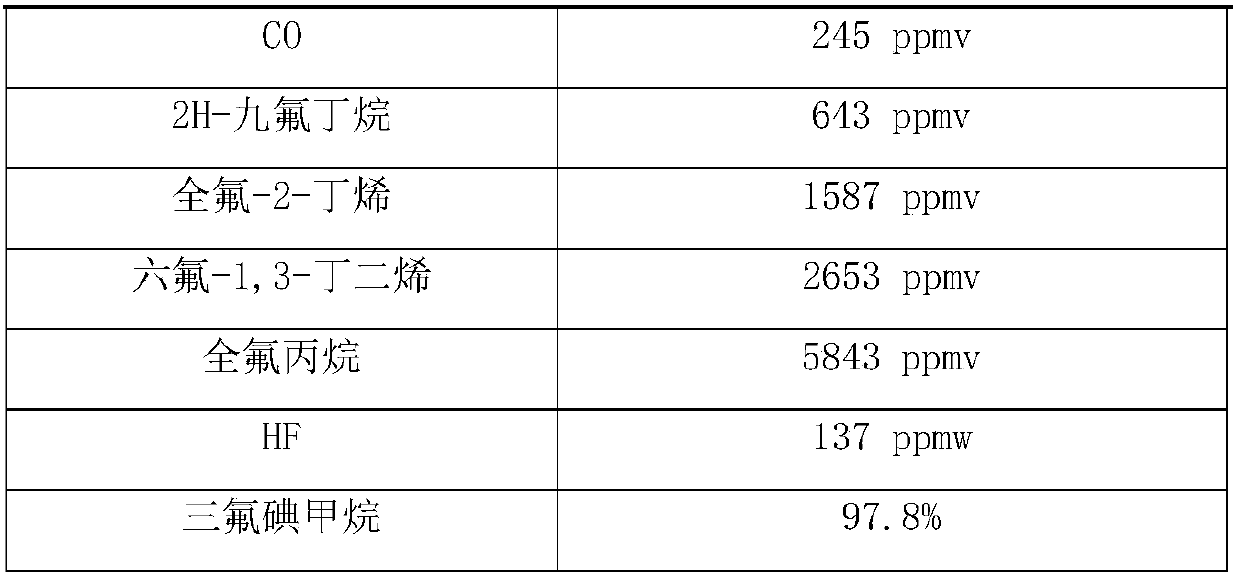

Embodiment 1

[0032] The raw material trifluoroiodomethane enters the two-stage adsorption column at a flow rate of 140g / h under the condition of 10°C and 0MPa. The first-stage adsorption column is filled with silica gel adsorbent, and the second-stage adsorption column is filled with 3A molecular sieve adsorbent to remove most of the water. and some organic impurities;

[0033] After adsorption, it is introduced into the rectification tower, and intermittent rectification is carried out at -10-0°C. The venting flow rate at the top of the tower is 0.3L / min, and the venting time is 30min. The purity of the top product is detected to be above 99.99%, and the product is discharged into the gas storage tank , filled into cylinders with a diaphragm compressor.

Embodiment 2

[0035] The raw material trifluoroiodomethane enters the two-stage adsorption column at a flow rate of 200g / h under the condition of 20°C and 0.1MPa. The primary adsorption column is filled with activated alumina adsorbent, and the secondary adsorption column is filled with 5A molecular sieve adsorbent. Most of water and some organic impurities;

[0036] After adsorption, it is introduced into the rectification tower, and intermittent rectification is carried out at -15~-10°C. The venting flow rate at the top of the tower is 0.5L / min, and the venting time is 20min. The purity of the top product is detected to be above 99.99%, and the product is discharged into the gas storage In the tank, fill it into the steel cylinder with a diaphragm compressor.

Embodiment 3

[0038] The raw material trifluoroiodomethane enters the two-stage adsorption column at a flow rate of 70g / h under the conditions of -10°C and -0.05MPa. The primary adsorption column is filled with silica gel adsorbent, and the secondary adsorption column is filled with 10X molecular sieve adsorbent. Most of water and some organic impurities;

[0039] After adsorption, it is introduced into the rectification tower, and intermittent rectification is carried out at -21~-16°C. The venting flow rate at the top of the tower is 0.8L / min, and the venting time is 10min. The purity of the top product is detected to be above 99.99%, and the product is discharged into the gas storage In the tank, fill it into the steel cylinder with a diaphragm compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com