Bottled grease micro emulsion freeze-dried preparation with 13 composite vitamins

A technology of freeze-dried preparations and fat-soluble vitamins, which is applied in the direction of freeze-dried delivery, drug combination, active ingredients of hydroxyl compounds, etc., to achieve the effects of avoiding side effects, avoiding pollution risks, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

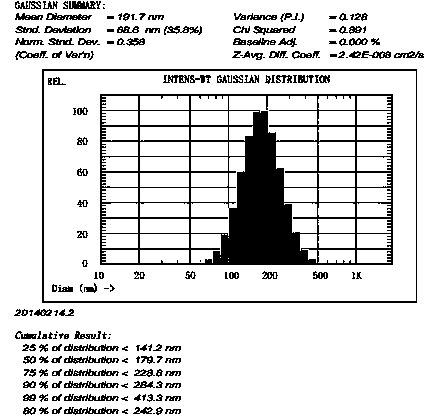

[0098] Example 1 A bottle of lipid microemulsion compounded with 13 kinds of vitamin freeze-dried preparations prepared with different proportions of phospholipid emulsifier content

example 11

[0099] Example 1.1 Prescription:

[0100]

[0101] Preparation:

[0102] (1) Dissolve the vitamin A, vitamin D, vitamin E, and vitamin K in the above prescription amount in soybean oil in a 60°C water bath under the protection of nitrogen. After the dissolution is complete, add the prescribed amount of egg yolk lecithin, and continue stirring until dissolved. Then add the prescribed amount of poloxamer and polyethylene glycol-cephalin derivatives, and continue to stir and dissolve until the solution is clear to form an oil phase mixture. At the same time, dissolve the prescribed amount of sodium oleate and water for injection in a 60°C water bath to completely form a water phase mixture, then slowly add the water phase mixture to the oil phase mixture to form colostrum, and then place the colostrum in a high-speed shearing machine Shear at 14000rpm for 10min, and finally place in a high-pressure homogenizer to homogenize 10 times under the pressure of 1250 bar to obtain a ...

example 12

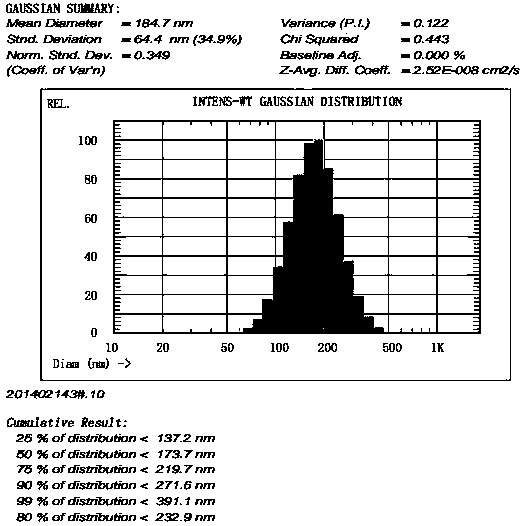

[0105] Example 1.2 Prescription:

[0106]

[0107] Preparation:

[0108](1) Dissolve the vitamin A, vitamin D, vitamin E, and vitamin K in the above prescription amount in soybean oil in a 60°C water bath under the protection of nitrogen. After the dissolution is complete, add the prescription amount of soybean lecithin, and continue stirring to dissolve until dissolved Then add the prescribed amount of poloxamer and polyethylene glycol-cephalin derivatives, and continue to stir and dissolve until the solution is clear to form an oil phase mixture. At the same time, dissolve the prescribed amount of sodium oleate and water for injection in a 60°C water bath to completely form a water phase mixture, then slowly add the water phase mixture to the oil phase mixture to form colostrum, and then place the colostrum in a high-speed shearing machine Shear at 14000rpm for 10min, and finally place in a high-pressure homogenizer and homogenize 12 times at a pressure of 1250 bar to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com