Method for preparing high-purity perfluoroisobutyronitrile

A technology of perfluoroisobutyronitrile and fluorine-containing olefins, which is applied to the purification/separation of carboxylic acid nitriles, organic chemistry, reagents, etc., can solve the problems of equipment and operator damage and injury, and achieve stable and reliable preparation process and high product quality. High yield, reasonable and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

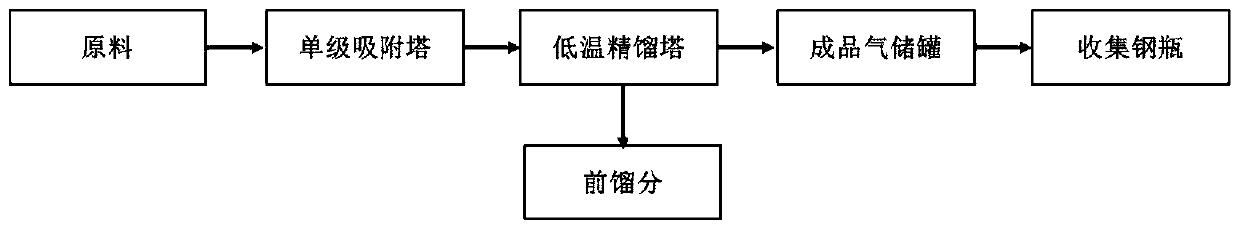

Method used

Image

Examples

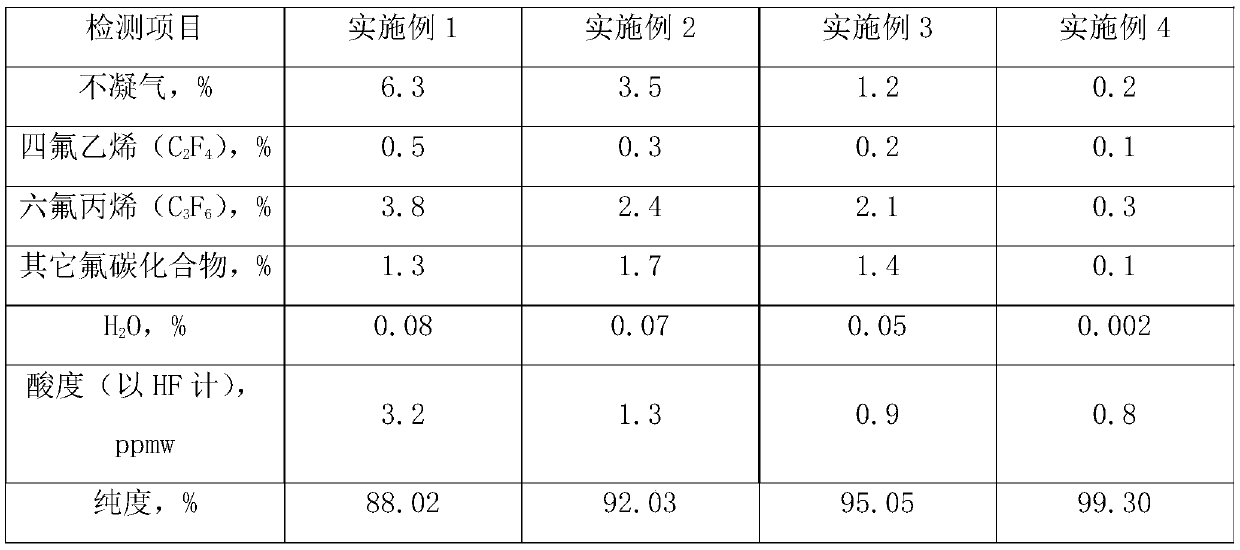

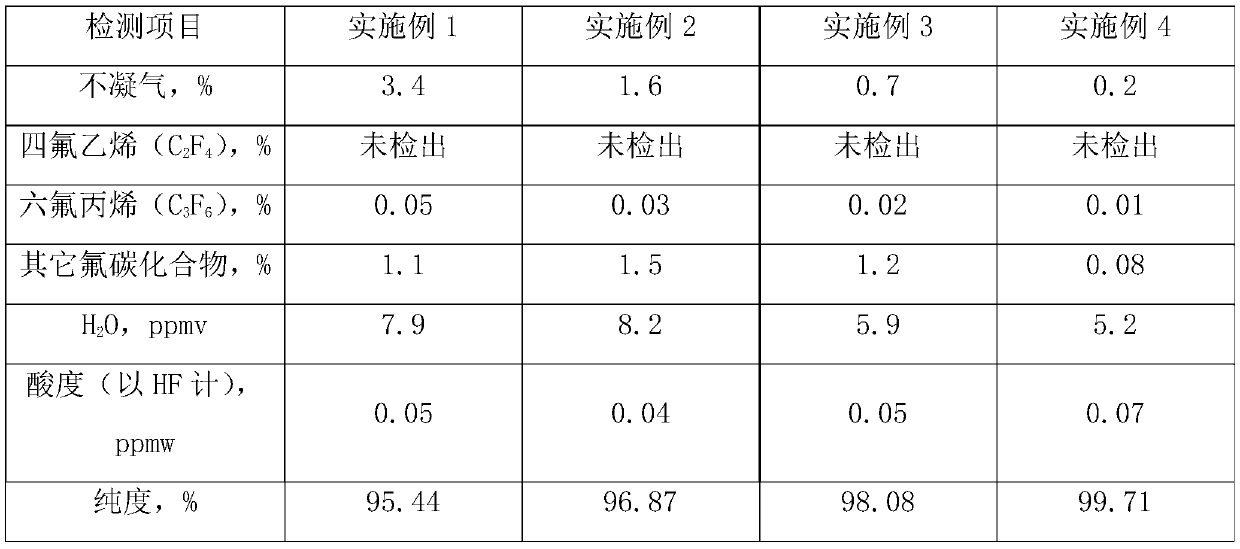

Embodiment 1

[0025] Pass 3 kg of crude perfluoroisobutyronitrile with a purity of 88% into a single-stage stainless steel adsorption tower at a rate of 0.2 L / min. The adsorption temperature is 25° C., the adsorption pressure is 0.1 MPa, the adsorbent is 5A molecular sieve, and the molecular sieve loading capacity is 10 kg. Collect the adsorbed perfluoroisobutyronitrile into the still of the rectification tower, a total of 2.7kg, adjust the rectification temperature to 10°C, and the pressure inside the tower to 0.03MPa. The flow rate of min is to discharge the former fraction. Use GC-PDHID gas chromatograph to analyze the purity of the fractions, and collect the fractions into the product gas storage tank after the purity is greater than 99.99%. The finished gas was filled into steel cylinders for storage by using a diaphragm compressor with a filling factor of 1.0, and finally 2.15 kg of purified product was obtained with a total yield of 81.6%.

Embodiment 2

[0027] Pass 3kg of crude perfluoroisobutyronitrile with a purity of 92% into a single-stage stainless steel adsorption tower at a rate of 0.5L / min, the adsorption temperature is 15°C, the adsorption pressure is 0.08MPa, the adsorbent is 10X molecular sieve, and the molecular sieve filling capacity is 8kg. Collect the adsorbed perfluoroisobutyronitrile into the still of the rectification tower, a total of 2.7kg, adjust the rectification temperature to 15°C, and the pressure inside the tower to 0.05MPa. The flow rate of min is to discharge the former fraction. Use GC-PDHID gas chromatograph to analyze the purity of the fractions, and collect the fractions into the product gas storage tank after the purity is greater than 99.99%. The finished product gas was filled into steel cylinders for storage by using a diaphragm compressor with a filling coefficient of 0.8, and finally 2.38 kg of purified product was obtained with a total yield of 86.1%.

Embodiment 3

[0029] Pass 3kg of crude perfluoroisobutyronitrile with a purity of 95% into a single-stage stainless steel adsorption tower at a rate of 1L / min, the adsorption temperature is 5°C, the adsorption pressure is 0.03MPa, the adsorbent is NaY molecular sieve, and the molecular sieve filling capacity is 5kg. Collect the adsorbed perfluoroisobutyronitrile into the still of the rectification tower, a total of 2.8kg, adjust the rectification temperature to 5°C, and the pressure inside the tower to 0.01MPa. The flow rate of min is to discharge the former fraction. Use GC-PDHID gas chromatograph to analyze the purity of the fractions, and collect the fractions into the product gas storage tank after the purity is greater than 99.99%. The finished product gas is filled into steel cylinders for storage by using a diaphragm compressor with a filling coefficient of 0.5, and finally 2.44 kg of purified product is obtained with a total yield of 85.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com