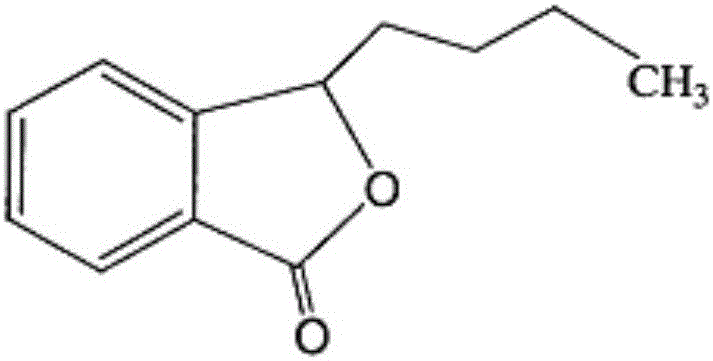

Butylphthalide fat emulsion injection and preparation process thereof

A technology of butylphthalide fat and emulsion injection, which is applied in the directions of emulsion delivery, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc., can solve the problems of butylphthalide being insoluble in water, etc. Simple and easy to implement, improve stability, reduce the effect of toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

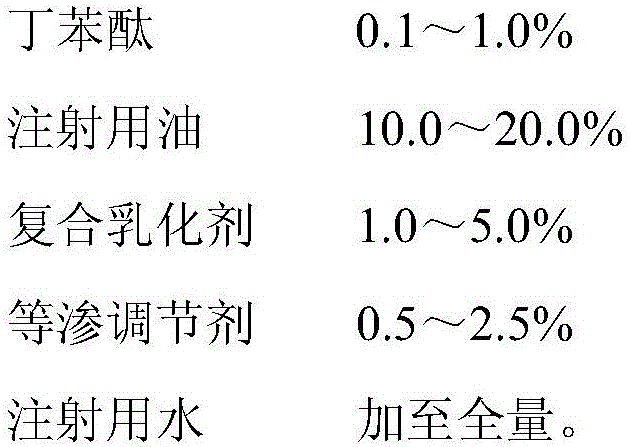

[0037] prescription:

[0038]

[0039] Preparation Process:

[0040] Dissolve refined butylphthalide in soybean oil and mix evenly to obtain an oil phase; dissolve glycerin for injection in 500ml water for injection and mix uniformly to obtain an aqueous phase; add lecithin and poloxamer to water phase, put it in a tissue masher, stir at high speed to a homogeneous liquid, then add the oil phase, stir at high speed to obtain colostrum.

[0041] Mix the colostrum twice under the pressure of 80Mpa through a high-pressure homogenizer, add water for injection to 1000ml, and mix once under the pressure of 70Mpa to obtain an emulsion, filter it through a 0.45μm microporous membrane, and fill it into a 100ml glass bottle In the process, sterilize at 121°C for 15 minutes, and after passing the inspection, the Butylphthalide Fat Emulsion Injection is obtained.

Embodiment 2

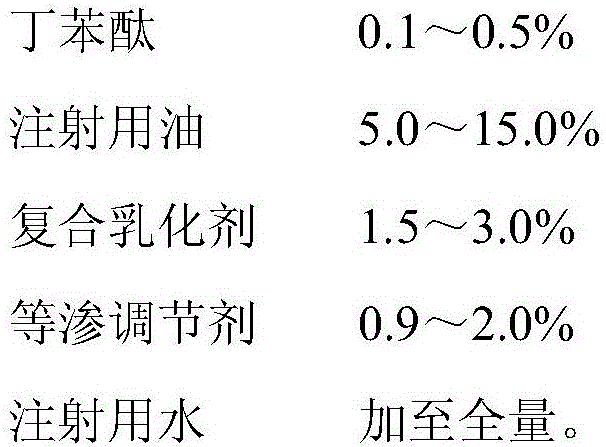

[0043] prescription:

[0044]

[0045] Preparation Process:

[0046] Extract refined butylphthalide, dissolve in rapeseed oil, and mix uniformly to obtain an oil phase; dissolve glycerin for injection in 500ml water for injection, and mix uniformly to obtain an aqueous phase; separately take lecithin and poloxamer Add it to the water phase, put it in a tissue grinder, stir at high speed until it becomes a homogeneous liquid, then add the oil phase, stir at high speed to obtain colostrum.

[0047] Mix the colostrum twice under the pressure of 80Mpa through a high-pressure homogenizer, add water for injection to 1000ml, and mix once under the pressure of 70Mpa to obtain an emulsion, filter it through a 0.45μm microporous membrane, and fill it into a 100ml glass bottle In the process, sterilize at 121°C for 15 minutes, and after passing the inspection, the Butylphthalide Fat Emulsion Injection is obtained.

Embodiment 3

[0049] prescription:

[0050]

[0051] Preparation Process:

[0052] Extract refined butylphthalide, dissolve it in cottonseed oil for injection, and mix evenly to obtain an oil phase; dissolve sodium chloride in 500ml water for injection, mix evenly, to obtain an aqueous phase; separately take lecithin and poloxa Add the milk to the water phase, put it in a tissue masher, stir at high speed to a homogeneous liquid, then add the oil phase, stir at high speed to obtain colostrum.

[0053] Mix the colostrum twice under the pressure of 80Mpa through a high-pressure homogenizer, add water for injection to 1000ml, and mix once under the pressure of 70Mpa to obtain an emulsion, filter through a 0.45μm microporous membrane, and fill it into a 10ml ampoule medium, 121 ° C high temperature sterilization for 15 minutes, after passing the inspection, the butylphthalide fat emulsion injection (small needle) is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com