High-performance and high-resistivity sintered samarium-cobalt permanent-magnet material and preparation method and application thereof

A high-resistivity, permanent magnet material technology, applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic circuits characterized by magnetic materials, etc., to achieve the effects of small size, convenient mass production, and high magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another aspect of the embodiments of the present invention also provides a method for preparing a high-performance and high-resistivity sintered samarium-cobalt permanent magnet material, which includes:

[0047] According to the chemical formula Sm(Co 1-a-b-c Fe a Cu b Zr c m y ) z Ingredients, where 0<a<0.5, 0<b<0.15, 0<c≤0.025, 0<y≤0.04, 6.5<z<8.5;

[0048] The alloy obtained after batching is sequentially subjected to orientation molding, sintering, heat treatment, and isothermal aging treatment to obtain a high-performance and high-resistivity sintered samarium-cobalt permanent magnet material, whose chemical formula is Sm(Co 1-a-b-c Fe a Cu b Zr c m y ) z , where 0<a<0.5, 0<b<0.15, 0<c≤0.025, 0<y≤0.04, 6.5<z<8.5, M is a high resistivity element.

[0049] In some embodiments, the high-resistivity element includes any one or a combination of two or more of In, Ga, Si, Ti, Na, Zr, B, Ca, Mg, Ge, Sn, and Bi, etc., But not limited to this.

[0050] In some...

Embodiment 1

[0080] (1) Ingredients: According to the stoichiometric formula Sm(Co 0.785 Fe 0.09 Cu 0.09 Zr 0.025 In 0.01 ) 7.68 Raw materials are weighed in the proportioning of each element;

[0081] (2) Smelting: put the raw materials prepared in step (1) into the vacuum induction melting furnace, cover the furnace cover and vacuumize to 5×10 -2 Pa, then bake at a lower temperature to remove the water vapor and gas adsorbed on the surface of the raw material, after the vacuum is stable (-2 Pa), and then filled with 0.06MPa high-purity argon (99.999%). Gradually increase the heating power, after the raw materials are completely melted, reduce the heating power, keep warm for 2 to 5 minutes, then pour into the water-cooled copper mold, and finally obtain the alloy ingot;

[0082] (3) Milling: Coarsely crush the alloy ingot smelted in step (2) to alloy particles with a size of 0.1-0.5 mm; then, the coarsely crushed alloy particles are made into a fine powder of 2-3 μm by jet mill to ...

Embodiment 2

[0088] The preparation method of the high-performance high-resistivity sintered samarium-cobalt permanent magnet material in this embodiment is basically the same as that of embodiment 1, the difference being that the proportioning of each element is: Sm(Co 0.78 Fe 0.09 Cu 0.09 Zr 0.025 In 0.015 ) 7.68 .

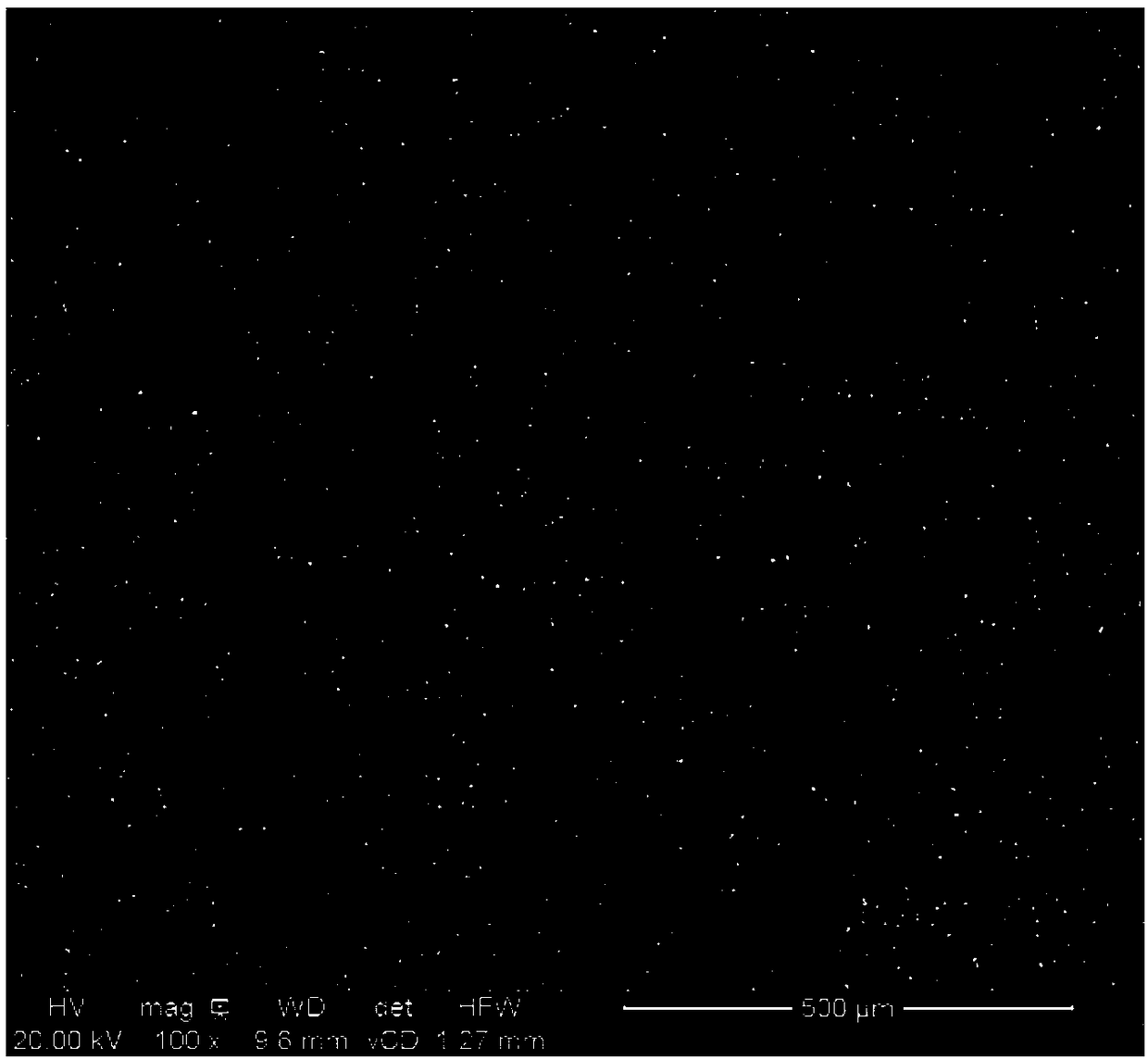

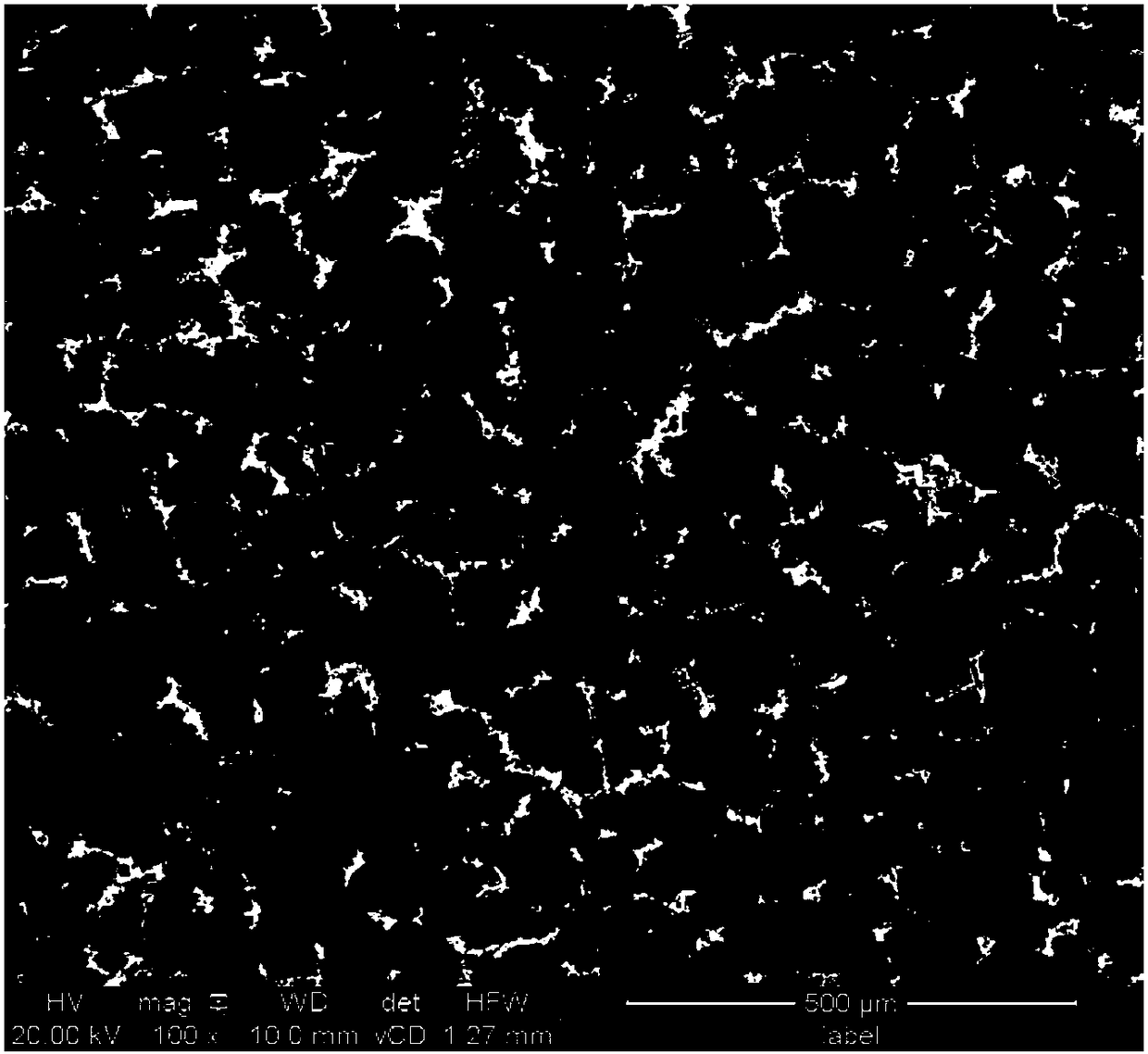

[0089] The scanning electron microscope photos of the microstructure of the high-performance and high-resistivity sintered samarium-cobalt permanent magnet material prepared in this example can be found in Figure 4 shown. Depend on Figure 4 It can be seen that the microstructure of the high-performance and high-resistivity sintered SmCo permanent magnet material is mainly composed of the main phase of the SmCo matrix and the grain boundary phase. The grain boundary phase is distributed along the grain boundary, and the grain size of the main phase is 100 μm. The size of the boundary phase was 10 μm. See Table 2 for the magnetic properties and resistivity parameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com