Device and method for producing hydrogen through step-by-step water electrolysis based on all-vanadium liquid flow redox medium

An all-vanadium liquid flow, electrolyzed water technology, applied in the field of electrolyzed water, can solve problems such as difficulty in large-scale regulation of gas production volume, and achieve the effects of reducing electrolysis voltage and regulating hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

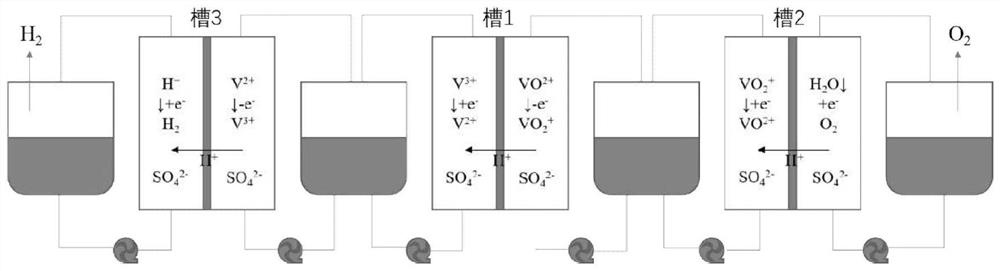

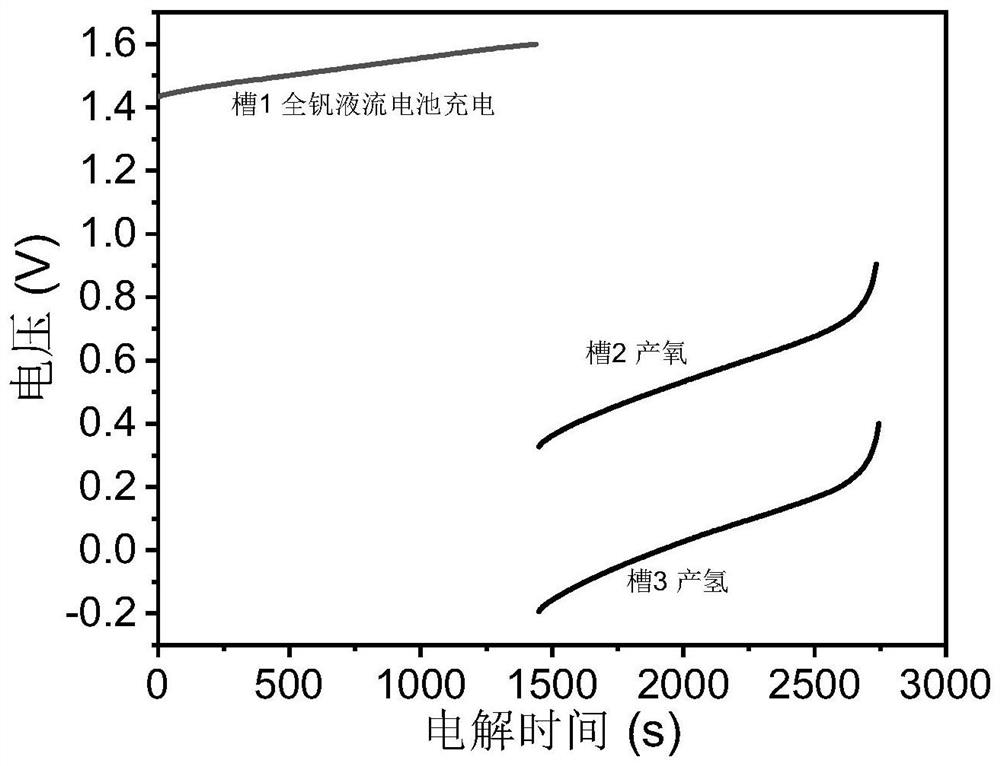

[0062] The cathode of tank 1 is connected to the storage tank to place 10 ml of electrolytically prepared 1 mol / L V 3+ 3 mol / L H 2 SO 4 , the anode connection storage tank is placed in 10 ml containing 1 mol / L VO 2+ 3 mol / L H 2 SO 4 , the cathode and anode electrodes are all graphite felts treated at 400°C for 24 hours in air. The catalytic electrode for the electrolysis of the anode of tank 2 to generate oxygen adopts an iridium dioxide / carbon composite electrode, and the anode is connected to the storage tank to place 10 milliliters of 3 mol / liter H 2 SO 4 , the cathode electrode is graphite felt treated at 400°C for 24 hours in air. The hydrogen evolution unit adopts the diaphragm electrolysis cell 3, and the catalytic electrode of the cathode electrolysis of the cell 3 to generate hydrogen adopts a platinum mesh electrode, and the cathode is connected to the storage tank to place 10 ml of 3 mol / L H 2 SO 4 , the cathode electrode is graphite felt treated at 400°C fo...

Embodiment 2

[0064] The cathode of tank 1 is connected to the storage tank to place 10 ml of electrolytically prepared 1 mol / L V 3+ 3 mol / L H 2 SO 4 , the anode connection storage tank is placed in 10 ml containing 1 mol / L VO 2+ 3 mol / L H 2 SO 4 , the cathode and anode electrodes are all graphite felts treated at 400°C for 24 hours in air. A ruthenium dioxide / carbon composite electrode is used as the catalytic electrode for the electrolysis of the anode of tank 2 to generate oxygen, and the anode is connected to the storage tank to place 10 milliliters of 3 mol / liter H 2 SO 4 , the cathode electrode is graphite felt treated at 400°C for 24 hours in air. The hydrogen evolution unit adopts the diaphragm electrolysis cell 3, and the catalytic electrode of the cathode electrolysis of the cell 3 to generate hydrogen adopts a platinum-carbon composite electrode, and the cathode is connected to the storage tank to place 10 ml of 3 mol / L H 2 SO 4 , the cathode electrode is graphite felt tr...

Embodiment 3

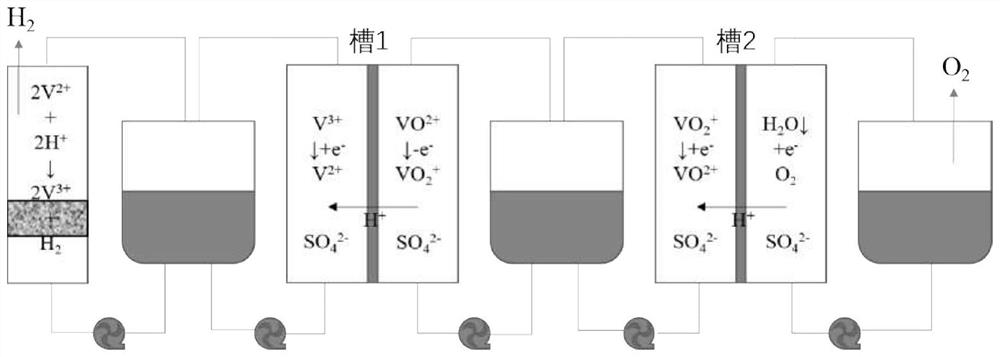

[0066] The cathode of tank 1 is connected to the storage tank to place 10 ml of electrolytically prepared 1 mol / L V 3+ 3 mol / L H 2 SO 4 , the anode connection storage tank is placed in 10 ml containing 1 mol / L VO 2+ 3 mol / L H 2 SO 4 , the cathode and anode electrodes are all graphite felts treated at 400°C for 24 hours in air. A ruthenium dioxide / carbon composite electrode is used as the catalytic electrode for the electrolysis of the anode of tank 2 to generate oxygen, and the anode is connected to the storage tank to place 10 milliliters of 3 mol / liter H 2 SO 4 , the cathode electrode is graphite felt treated at 400°C for 24 hours in air. The hydrogen evolution unit adopts a chemical catalytic solid-liquid reaction tank, and the catalyst uses molybdenum carbide particles. The area of all electrodes is 10 square centimeters, and the diaphragm is selected from 10 square centimeters of Nafion117 film, and a constant current electrolysis is carried out by using a curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com