Method for simultaneously obtaining hydrogen and biomass fuel rod by using biomass raw material

A biomass raw material and biomass fuel technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of low hydrogen production efficiency, high energy consumption, complex process, etc., to reduce energy consumption and water consumption , Effective utilization and cleaning effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

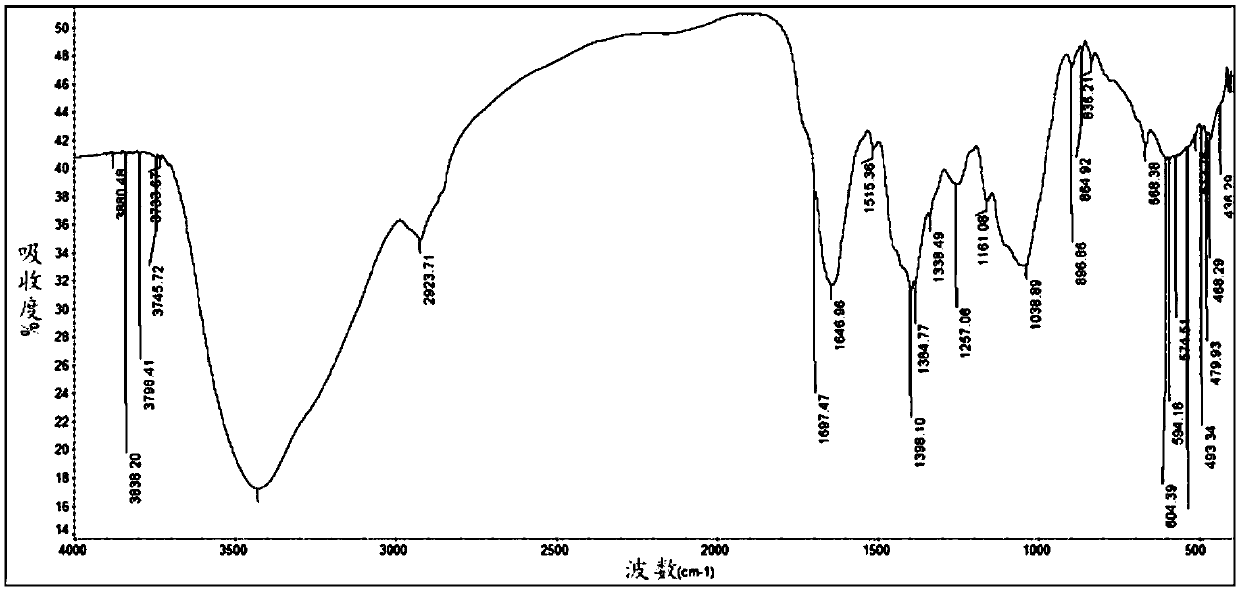

Embodiment 1

[0044] (1) Add 5 grams of dry corn stalks to 100 ml of aqueous solution, and add 3 grams of Fe 2 (SO 4 ) 3 ·7H 2 O, put the mixed solution in a pressure-resistant hydrothermal reactor, and heat it at 5°C min -1 Heat the reactor to 150°C, stay at this temperature for 1 hour, then cool down to room temperature naturally;

[0045] (2) The product after the hydrothermal reaction is subjected to solid-liquid separation, the solid substance is retained in the hydrothermal reaction kettle, and the liquid substance is used as the positive electrode electrolyte;

[0046] (3) Use the liquid after the hydrothermal reaction as the positive electrolyte of the electrolytic cell, use the polymer solid electrolyte as the diaphragm, apply a voltage of 1V, and perform constant voltage electrolysis until the current density is ≤ 1mA cm -2 , while collecting hydrogen at the negative electrode;

[0047] (4) The positive electrode electrolyte after electrolysis is mixed with the solid matter a...

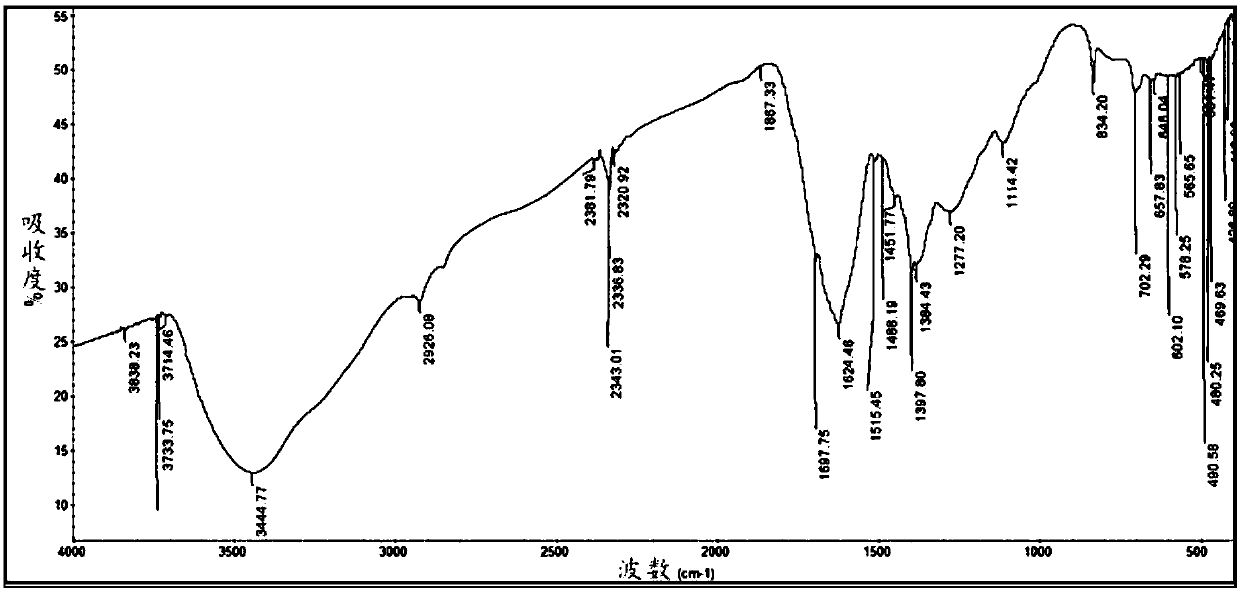

Embodiment 2

[0052] (1) Add 3 grams of dry pine wood powder to 100 ml of aqueous solution, and add 5 grams of FeCl at the same time 3 ·6H 2 O, put the mixed solution in a pressure-resistant hydrothermal reactor, and heat it at 4°C min -1 Heat the reactor to 200°C, stay at this temperature for 2 hours, then cool down to room temperature naturally;

[0053] (2) The product after the hydrothermal reaction is subjected to solid-liquid separation, the solid substance is retained in the hydrothermal reaction kettle, and the liquid substance is used as the positive electrode electrolyte;

[0054] (3) Use the liquid after the hydrothermal reaction as the positive electrolyte of the electrolytic cell, use the polymer solid electrolyte as the diaphragm, apply a voltage of 0.9V, and perform constant voltage electrolysis until the current density is ≤ 1mA cm -2 , while collecting hydrogen at the negative electrode;

[0055] (4) The positive electrode electrolyte after electrolysis is mixed with the...

Embodiment 3

[0060] (1) Add 10 grams of directly harvested lawn grass to 100 ml of water solution, and add 3 grams of VOSO at the same time 4 ·3H 2 O, put the mixed solution in a pressure-resistant hydrothermal reactor, and heat it at 3°C min -1 Heat the reactor to 180°C, stay at this temperature for 3 hours, then cool down to room temperature naturally;

[0061] (2) The product after the hydrothermal reaction is subjected to solid-liquid separation, the solid substance is retained in the hydrothermal reaction kettle, and the liquid substance is used as the positive electrode electrolyte;

[0062] (3) Use the liquid after the hydrothermal reaction as the positive electrolyte of the electrolytic cell, use the polymer solid electrolyte as the diaphragm, apply a voltage of 1.5V, and perform constant voltage electrolysis until the current density is ≤ 1mA cm -2 , while collecting hydrogen at the negative electrode;

[0063] (4) The positive electrode electrolyte after electrolysis is mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com