Aqueous transparent heat insulation paint and its preparation method

A heat-insulating coating, transparent technology, applied in the direction of coating, etc., can solve the problems of poor heat insulation performance and wear resistance, easy aging and falling off, complex components, etc., and achieve excellent performance, good heat insulation effect and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] A kind of water-based transparent heat insulating coating of the present embodiment, its component is:

[0087] Nano-indium tin oxide composite powder (nano-ITO) 5.0 kilograms (Kg)

[0088] The particle size of nano ITO powder is 20nm-50nm.

[0089] Distilled water 37.5 kilograms (Kg)

[0090] Water-based fluorocarbon resin emulsion FEVE emulsion (Changxing Chemical Industry 4312) 50 kilograms (Kg)

[0091] HDI curing agent 8.5 kilograms (Kg)

[0092] Its preparation method comprises the following steps:

[0093] (1) First, weigh the amount of various raw materials according to the parts by weight of each component contained in the water-based transparent heat-insulating coating.

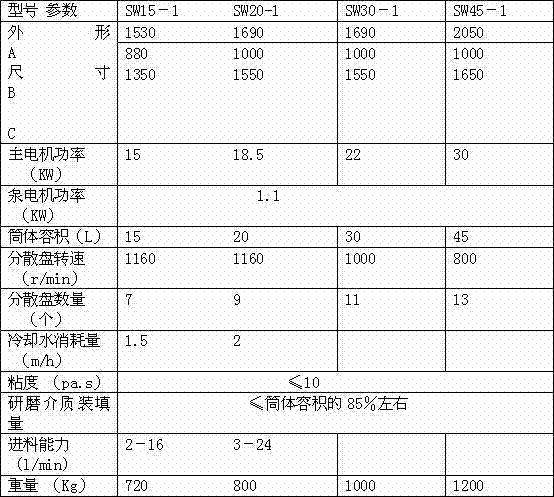

[0094] (2) Add distilled water into the reaction vessel, and under the condition of high-speed dispersion, add nano-ITO powder into the distilled water at a rate of - g / min, and disperse at high speed for 25 minutes to form a slurry. The high-speed dispersion is stirring at 1160 rp...

Embodiment 2

[0104] A kind of water-based transparent heat insulating coating of the present embodiment, its component is:

[0105]Nano-indium tin oxide composite powder (nano-ITO) 2.0 kilograms (Kg)

[0106] The particle size of nano ITO powder is 20nm-50nm.

[0107] Distilled water 40.5 kilograms (Kg)

[0108] Water-based fluorocarbon resin emulsion FEVE emulsion (Dalian Zhenbang F600) 45.0 kilograms (Kg)

[0109] HDI curing agent 8.0 kilograms (Kg)

[0110] Its preparation method comprises the following steps:

[0111] (1) First, weigh the amount of various raw materials according to the parts by weight of each component contained in the water-based transparent heat-insulating coating.

[0112] (2) Add distilled water into the reaction vessel, and under the condition of high-speed dispersion, add nano-ITO powder into the distilled water at a rate of - g / min, and disperse at high speed for 20 minutes until a slurry is formed. The high-speed dispersion is to use a conventional di...

Embodiment 3

[0117] A kind of water-based transparent heat insulating coating of the present embodiment, its component is:

[0118] Nano-indium tin oxide composite powder (nano-ITO) 3.5 kilograms (Kg)

[0119] The particle size of nano ITO powder is 20nm-50nm.

[0120] Distilled water 39.0 kilograms (Kg)

[0121] Water-based fluorocarbon resin emulsion FEVE emulsion (Changshu Zhonghao 2H-01) 55.0 kilograms (Kg)

[0122] HDI curing agent 9.0 kilograms (Kg)

[0123] Its preparation method comprises the following steps:

[0124] (1) First, weigh the amount of various raw materials according to the parts by weight of each component contained in the water-based transparent heat-insulating coating.

[0125] (2) Add distilled water into the reaction vessel, and under the condition of high-speed dispersion, add nano-ITO powder into the distilled water at a rate of - g / min, and disperse at high speed for 35 minutes to form a slurry. The high-speed dispersion is stirring at 1200 rpm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com