Method for preparing mono-/multi-valent ion exchange membrane by membrane fouling and electrodialysis deposition

An ion exchange membrane and multivalent ion technology, which is used in the field of membrane fouling-electrodialysis deposition to prepare a multivalent ion exchange membrane, can solve the problems of easy peeling off of the surface skin, poor long-term stability, low selection coefficient, etc., and achieves a wide range of raw material sources. , the effect of high limiting current density and low film resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

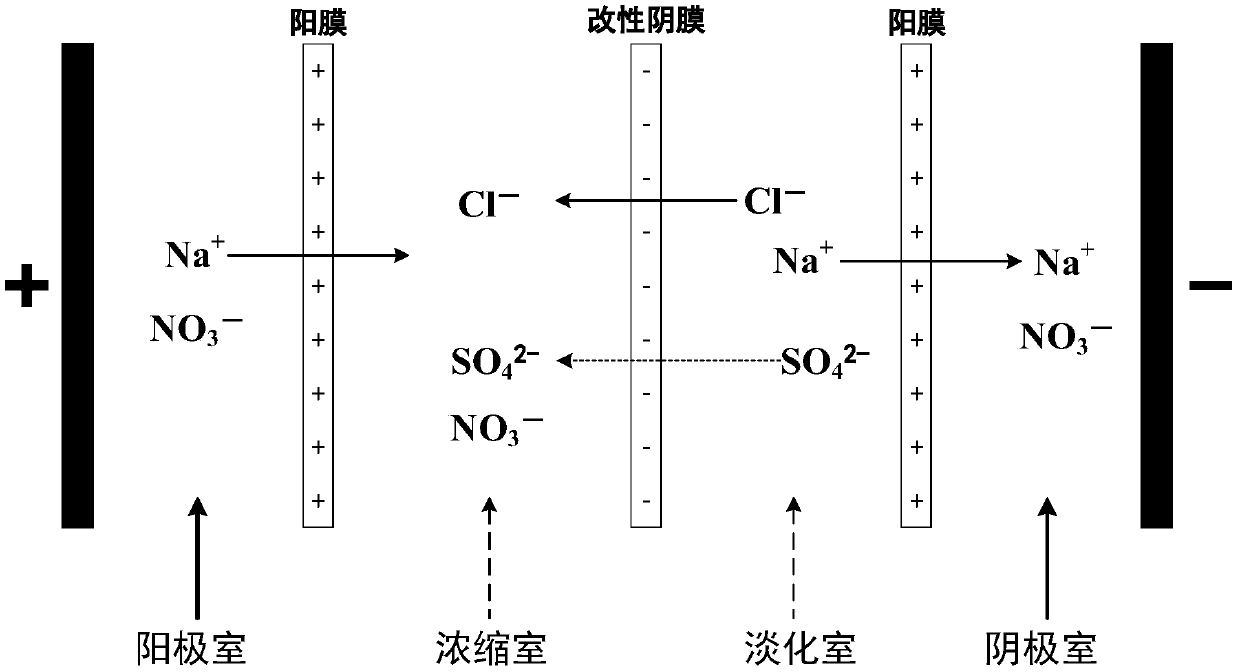

[0035] In this example, the commercialized Neosepta AMX membrane was polluted with sulfonated polyphenylene ether (SPPO) to obtain a multivalent anion selective permeation membrane with selective permeation ability for monovalent ions. The specific steps are as follows:

[0036] 1. Preparation of the target pollutant solution: 1 g of sulfonated polyphenylene ether (SPPO) with a sulfonation degree of 28% was dissolved in 35 mL of nitrogen-nitrogen dimethylformamide (DMF), magnetically stirred until the SPPO was completely dissolved, and then Add deionized water to the solution and dilute to 500mL; take 5mL of NaCl solution with a concentration of 0.5mol / L and add it to the sulfonated polyphenylene ether solution, stir magnetically until the solution is uniformly dispersed, and then continue to add deionized water to dilute to 1000mL.

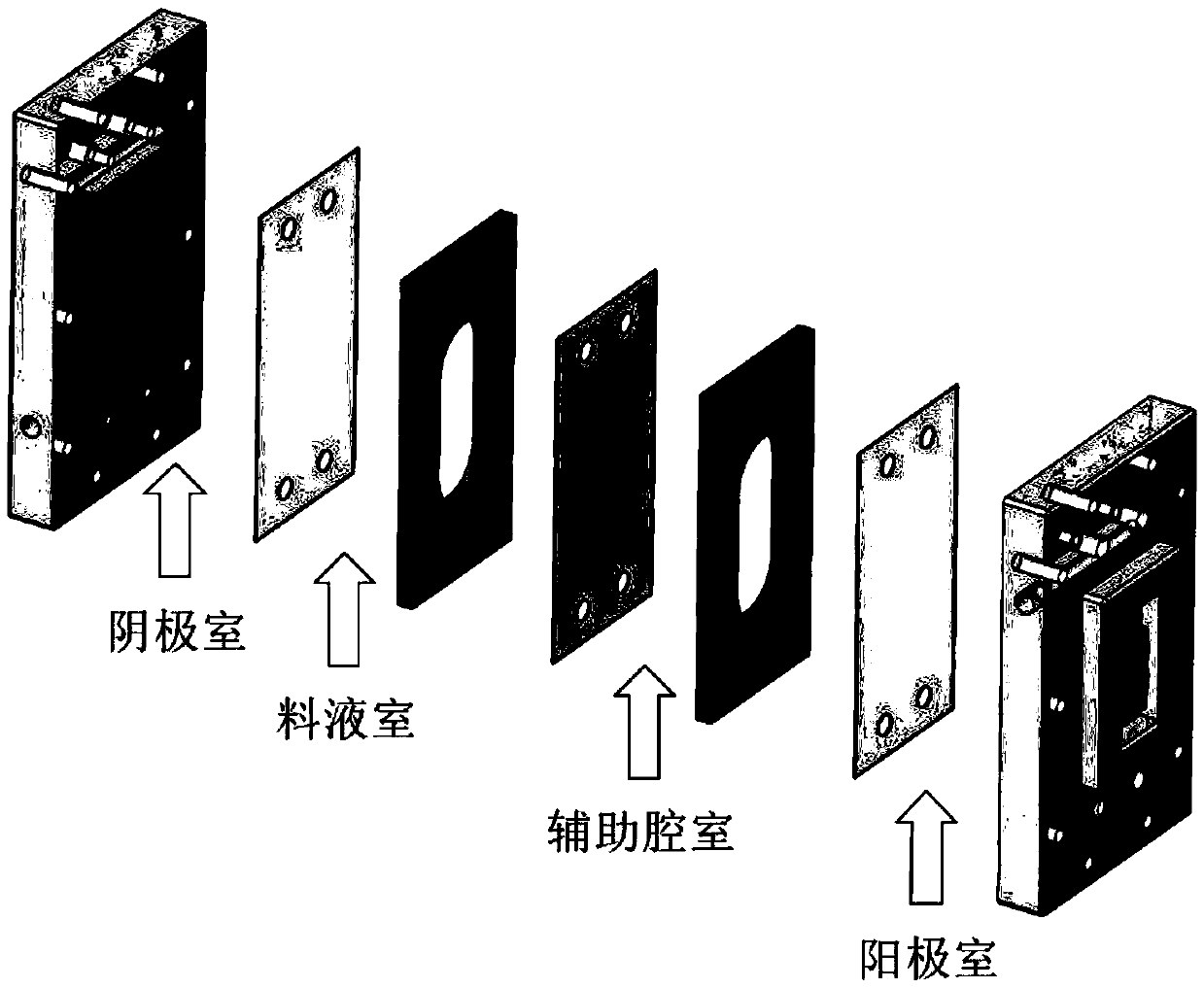

[0037] 2. Assemble the electrodialysis device: such as figure 1As shown, the electrodialysis device is based on the anode plate, silica gel gask...

Embodiment 2

[0047] In this embodiment, a multivalent anion selective permeable membrane is prepared in the same manner as in Example 1, the difference is that in step 4, 30mA / cm 2 current.

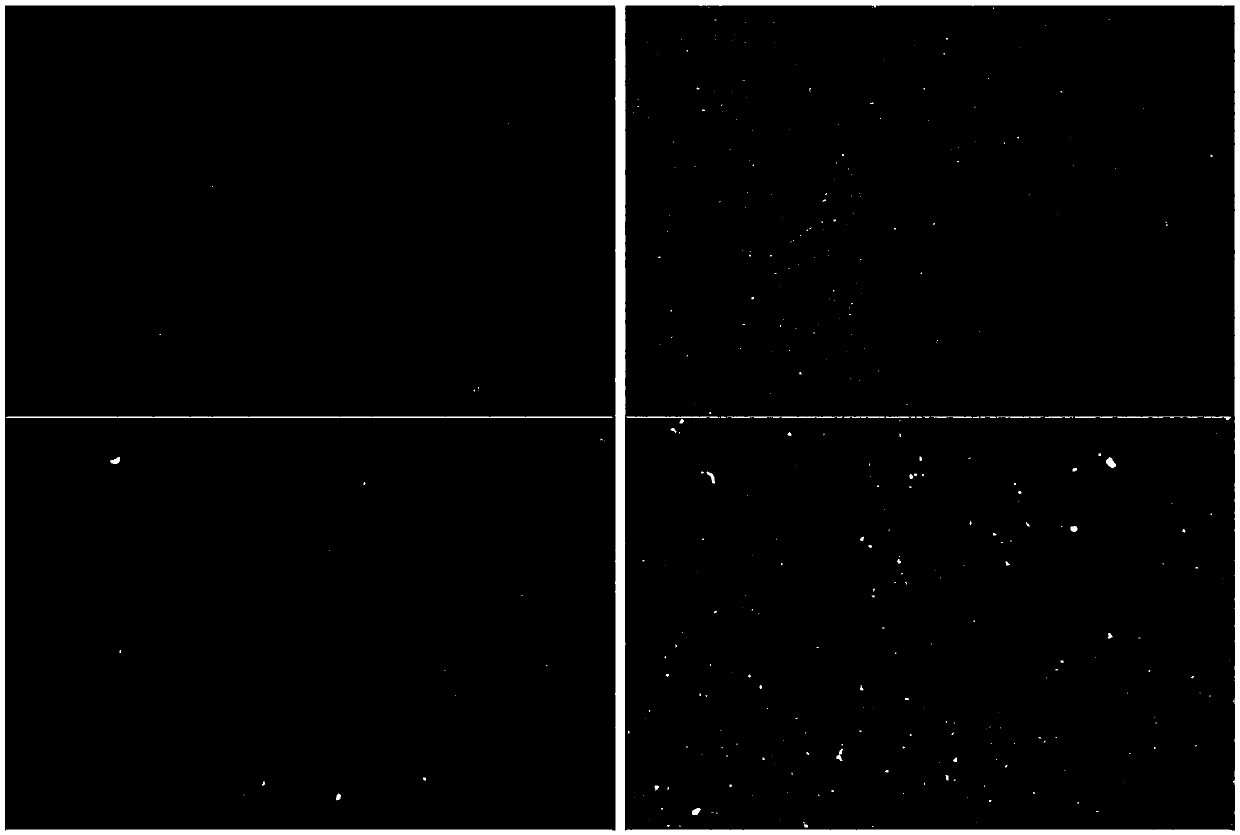

[0048] Through characterization and testing, the selectivity coefficient of the anion exchange membrane (MAEM-10) after the modification of the present embodiment is shown in Table 1, and the geometric structure of the surface is as follows image 3 As shown, the infrared spectrum is shown as Figure 4 As shown, the I-V curve is shown as Figure 5 shown.

Embodiment 3

[0050] In this embodiment, a multivalent anion selective permeable membrane is prepared in the same manner as in Example 1, the difference is that in step 4, a 50mA / cm 2 current.

[0051] Through characterization and testing, the selectivity coefficient of the anion exchange membrane (MAEM-10) after the modification of the present embodiment is shown in Table 1, and the geometric structure of the surface is as follows image 3 As shown, the infrared spectrum is shown as Figure 4 As shown, the I-V curve is shown as Figure 5 shown.

[0052] Table 1 Selectivity coefficient list of modified anion exchange membrane

[0053]

[0054]

[0055] *T-5 means the current density of the test is 5mA / cm 2 , the same T-10 and T-20 refer to the test current density of 10mA / cm 2 and 20mA / cm 2 .

[0056] It can be seen from the surface scanning electron microscope that the surface of the modified anion exchange membrane is smoother than that of the unmodified anion exchange membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com