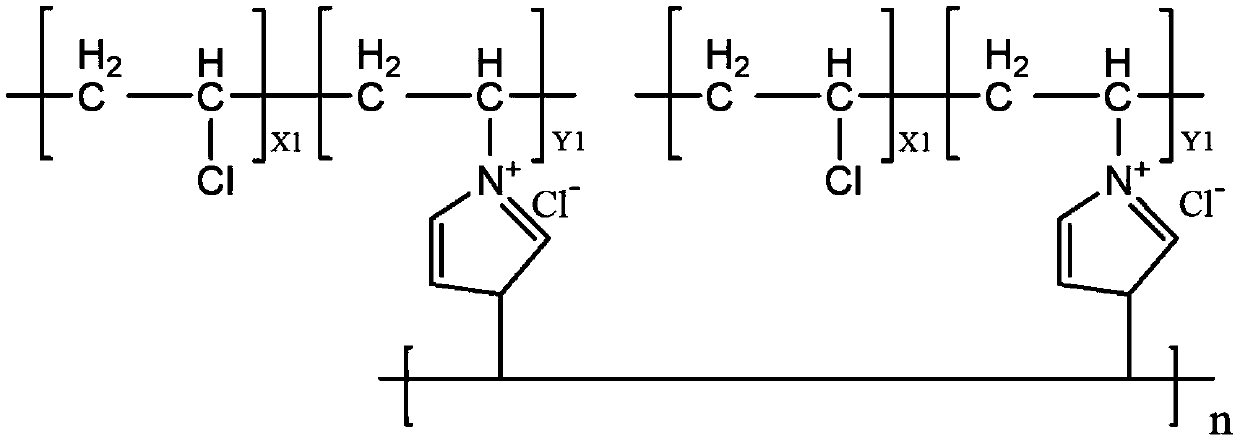

Preparation method of homogeneous PVC-based anion exchange membrane

An anion exchange membrane and base membrane technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of non-crosslinked network structure, complex preparation process, uneven impregnation, etc., and achieve good dimensional stability , The process is simple and the price is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the homogeneous PVC base anion exchange membrane of this example, its steps are:

[0027] PVC and N,N-dimethylformamide are configured into a uniform casting solution according to a mass ratio of 15:100; mm, the number of meshes is 100 meshes) on the coating film, treated in a hot water tank and dried to form a PVC base film with a thickness of 0.12mm; the pore size of the PVC base film is 0.5 microns; 1-vinylimidazole and azobis The isobutyronitrile is configured into a uniform monomer mixed solution according to the mass ratio of 100:0.5; the PVC base film is soaked in the monomer mixed solution, and the soaking temperature is controlled at 65°C, and the soaking time is 5h. The soaked PVC base film and the polyester protective film are stacked at intervals, compressed and rolled up, and then polymerized at 85°C for 20 hours, and then the polyester protective film is peeled off to obtain a roll-type homogeneous PVC anion exchange membrane.

...

Embodiment 2

[0030] The preparation method of the homogeneous PVC base anion exchange membrane of this example, its steps are:

[0031] PVC and N,N-dimethylacetamide are configured into a uniform casting solution according to a mass ratio of 25:100; 100 mesh) coating film, treated in a hot water tank and dried to form a PVC base film with a thickness of 0.14mm; the pore diameter of the PVC base film is 0.3 micron; 1-vinylimidazole and dibenzoyl peroxide The mass ratio is 100:0.5 to configure a uniform monomer mixed solution; soak the PVC base film in the monomer mixed solution, control the soaking temperature to 65°C, and the soaking time to 6h. The soaked PVC base film and the polyester protective film are stacked at intervals, pressed tightly and rolled up, and then polymerized at 90°C for 24 hours, and then peeled off the polyester protective film to obtain a roll-type homogeneous PVC anion exchange membrane.

[0032] According to the measurement method described in the industry stand...

Embodiment 3

[0034] The preparation method of the homogeneous PVC base anion exchange membrane of this example, its steps are:

[0035] The PVC and N-methylpyrrolidone are configured into a uniform casting solution according to the mass ratio of 40:100; after the casting solution is ultrasonically degassed, it is placed on a nylon mesh cloth (the thickness of the mesh is 0.1mm, and the mesh number is 80 mesh) The upper coating film is treated and dried in a hot water tank to form a PVC base film with a thickness of 0.15mm; the pore size of the PVC base film is 0.01 micron; : 0.5 to prepare a uniform monomer mixed solution; soak the PVC base film in the monomer mixed solution, control the soaking temperature to 45°C, and the soaking time to 8h. The soaked PVC base film and the polyester protective film are stacked at intervals, pressed tightly and rolled up, and then polymerized at 90°C for 24 hours, and then peeled off the polyester protective film to obtain a roll-type homogeneous PVC ani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com