Reinforced perfluorosulfonic acid ion exchange membrane for chloride electrolysis, and preparation method thereof

A perfluorosulfonic acid ion and perfluorosulfonic acid technology, applied in the field of ion exchange membranes, can solve the problems of affecting the ion exchange capacity of the basement membrane, increasing the resistance of the basement membrane, and low exchange capacity, so as to achieve easy industrial production and low membrane resistance , Improve the effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

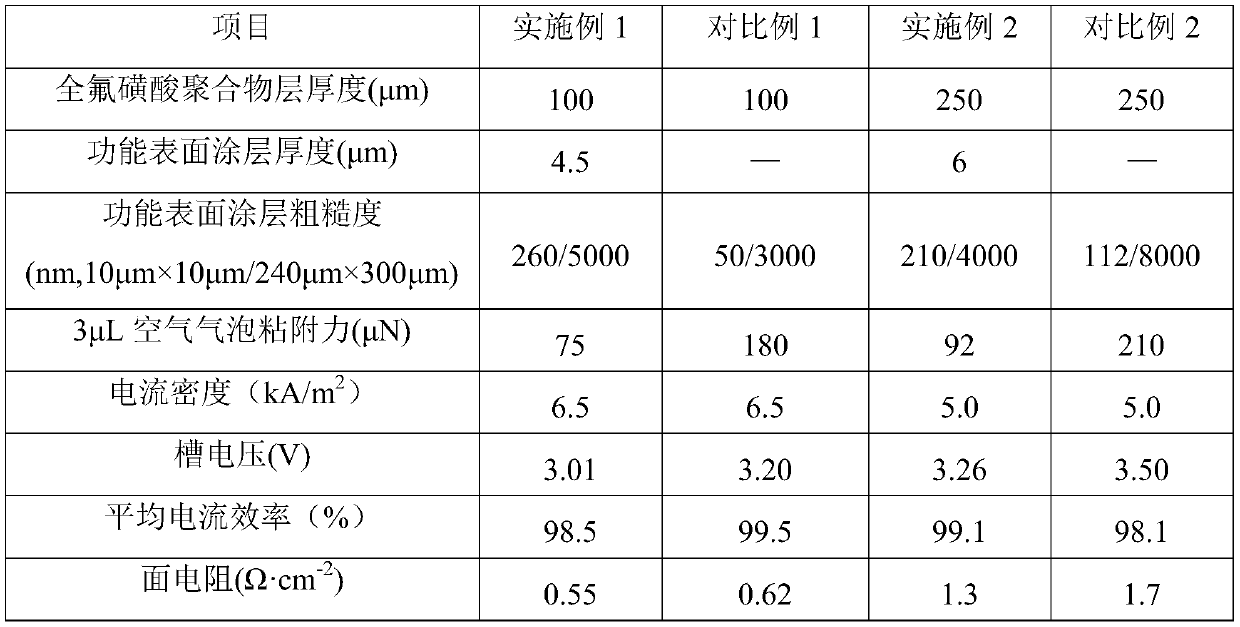

Embodiment 1

[0033] The preparation method of the described reinforced perfluorosulfonic acid ion exchange membrane for chloride electrolysis comprises the following steps:

[0034] (1) The perfluoroion exchange resin base film is obtained by extrusion casting of perfluorosulfonic acid resin of IEC=1.08mmol / g, wherein the thickness of the perfluorosulfonic acid resin layer is 100 μm, and polytetrafluoroethylene and silk The composite braided reinforcing material net was soaked in ultrasonically treated trifluorotrichloroethane solvent for 1.5 hours, the thickness of the porous reinforcing material was 50 μm, the volume ratio of polytetrafluoroethylene and silk was 1:1, and the porosity of the reinforcing material net 30%, take it out and dry it, and then compound it with the perfluoroion exchange resin base membrane by rolling to form the precursor of the perfluorosulfonic acid ion exchange membrane;

[0035] (2) under the temperature of 180 ℃, under the pressure of 120 tons, the perfluori...

Embodiment 2

[0050] The preparation method of the described reinforced perfluorosulfonic acid ion exchange membrane for chloride electrolysis comprises the following steps:

[0051] (1) The perfluoroion exchange resin base film is obtained by extrusion casting of perfluorosulfonic acid resin of IEC=0.75mmol / g, wherein the thickness of the perfluorosulfonic acid resin layer is 250 μm, and polytetrafluoroethylene and silk The composite braided reinforcing material net was soaked in ultrasonically treated trifluorotrichloroethane solvent for 1.5 hours. The thickness of the porous reinforcing material was 100 μm, the volume ratio of polytetrafluoroethylene and silk was 1:2, and the porosity of the reinforcing material net 20%, take it out and dry it, and then compound it with the perfluoroion exchange resin base membrane by rolling to form the precursor of the perfluorosulfonic acid ion exchange membrane;

[0052] (2) under the temperature of 210 ℃, under the pressure of 100 tons, with the per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com